Anti-backflow ventilation plate for power box

A ventilation plate, anti-backflow technology, applied in the cooling/ventilation of substation/switchgear, substation/distribution device casing, etc., can solve the problem of insufficient waterproof, dustproof, thermal insulation, and easy water entry at the vent. , small animals are easy to invade, etc., to achieve the effect of simple structure, simple manufacture and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

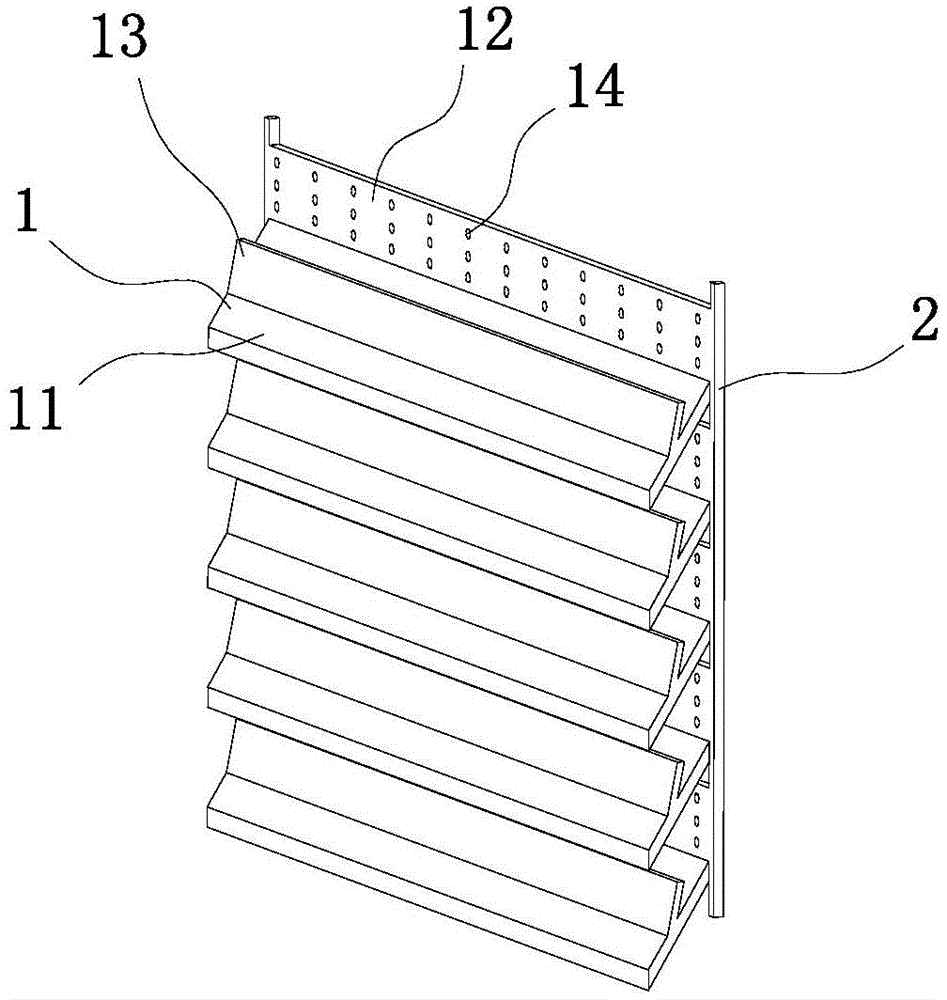

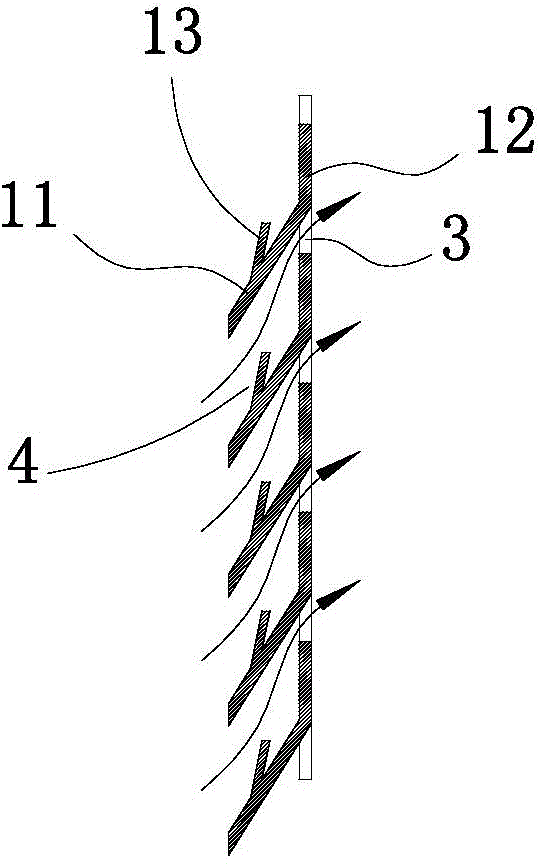

[0012] Such as figure 1 As shown, the anti-backflow ventilation panel of the power box of the present embodiment includes a ventilation panel body, and the ventilation panel body includes a frame body 2 and a plurality of wind deflectors 1 installed in the frame body 2, and the two ends of the wind deflector 1 are connected to The frame body 2 is fixedly connected, and the air guide plate 1 is arranged at intervals up and down; The surfaces are parallel, the upper and lower adjacent lead-in plates 11 have lead-in grooves 4, and the adjacent lead-out plates 12 have lead-out grooves 3;

[0013] The upper surface of the lead-in plate 11 is provided with an anti-backflow plate 13 inclined toward the lead-out plate 12 , and the lead-out plate 12 is evenly distributed with guide holes 14 .

[0014] The invention adopts the folded plate structure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com