Electric power cabinet structure with ventilating pressure-reducing plate

A technology for power cabinets and ventilation panels, which is applied in the cooling/ventilation of substations/switchgears, substations/distribution equipment shells, etc., and can solve problems such as insufficient air convection, poor heat dissipation, and poor natural outflow effects. Achieve the effect of avoiding local high fever and cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

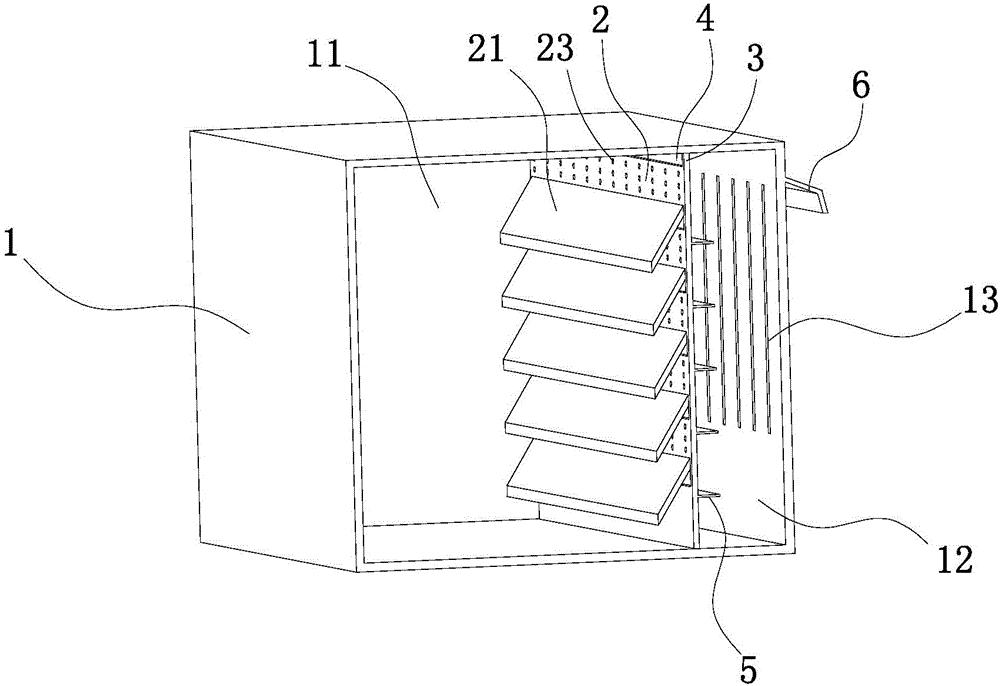

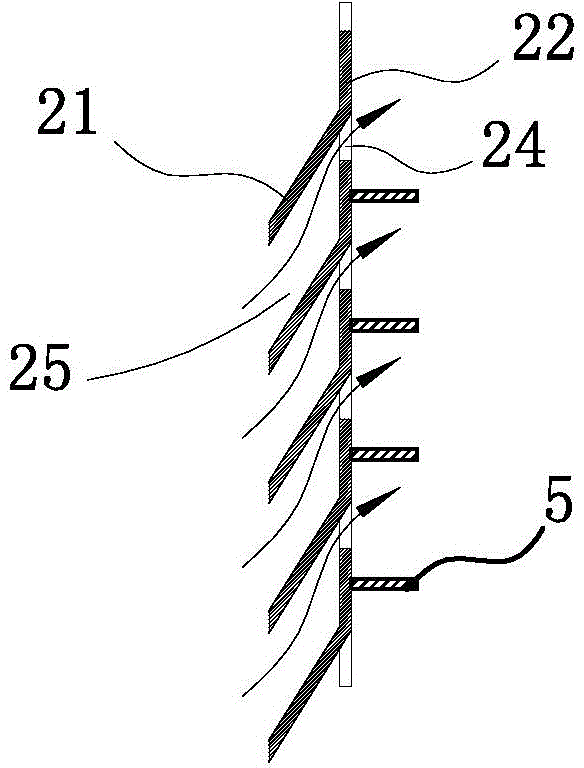

[0012] like figure 1 , figure 2 As shown, the structure of the power cabinet with ventilation and decompression plates in this embodiment includes a cabinet body 1 and a ventilation panel 2 inside the cabinet body 1, and the ventilation panel 2 divides the interior of the cabinet body 1 into an electrical device installation cavity 11 and a ventilation and heat dissipation cavity 12. The side wall of the ventilation and heat dissipation cavity 12 has a ventilation groove 13; the ventilation plate is fixedly connected with the cabinet body 1 by means of the frame body 3 on both sides, and the upper end of the ventilation plate 1 and the inner top surface of the cabinet body 1 have a ventilation top gap 4 The ventilation plate 2 includes an airflow introduction plate 21 and an airflow derivation plate 22, the introduction plate 21 is arrange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com