Automatic spray boom obstacle-avoiding mechanism for boom sprayer

A technology of automatic obstacle avoidance and spraying machine, which is applied in the fields of catching or killing insects, applications, animal husbandry, etc. It can solve the problems that the spray boom does not have automatic obstacle avoidance function, the spray quality drops, and the spray boom truss is damaged. Reliable obstacle avoidance performance, good operation quality and high safety in use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

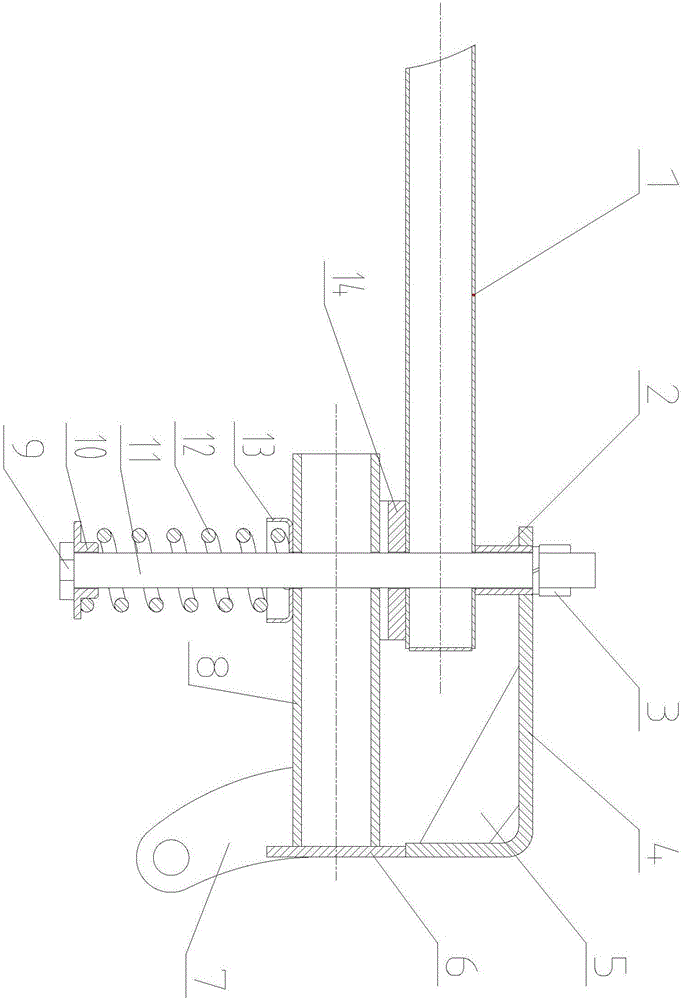

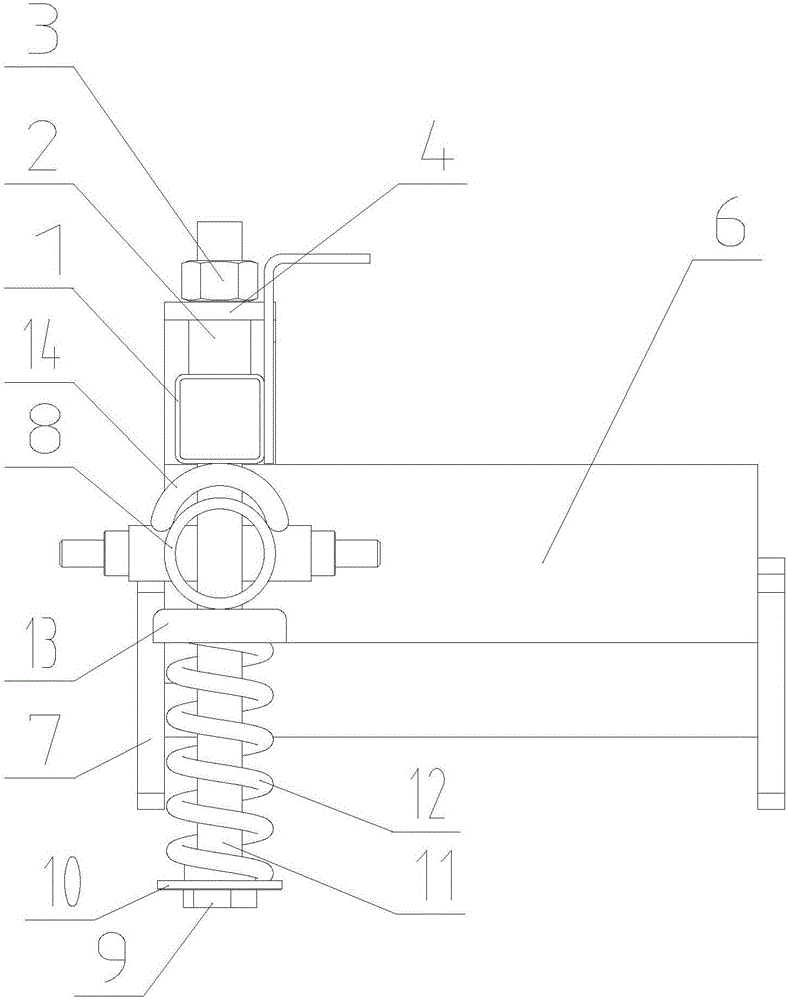

[0009] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. An automatic obstacle avoidance mechanism for the spray bar of a spray bar sprayer includes a spray bar frame tail section 1, hinge plates 7 are respectively fixed on the opposite ends of the end plate 6, and angle plates are fixed on the upper end of the end plate 6. Shaped support plate 4, on the side of the end plate 6, the clutch tube 8 is fixed, and the clutch drive shaft 11 can be moved up and down and installed on the angular support plate 4 and the clutch tube 8. 11 Install the spring seat 13, the pressure spring 12, the gland 10 and the pressure regulating nut 9 from top to bottom on the lower side of the clutch tube 8. The upper and lower ends of the pressure spring 12 are connected to the spring seat respectively. 13 is in contact with the gland 10, and the spring seat 13 is pressed against the lower wall of the clutch tube 8, and the gland 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com