Enhanced robot workbench based on multiple depth cameras

A robot workbench and depth camera technology, applied in the direction of instruments, manipulators, manufacturing tools, etc., can solve the problems of not being able to obtain the robot environment, affecting the accuracy of three-dimensional coordinates, affecting object matching, etc., to reduce the area, improve efficiency, and enhance vision perceived effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the present invention more specifically, the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

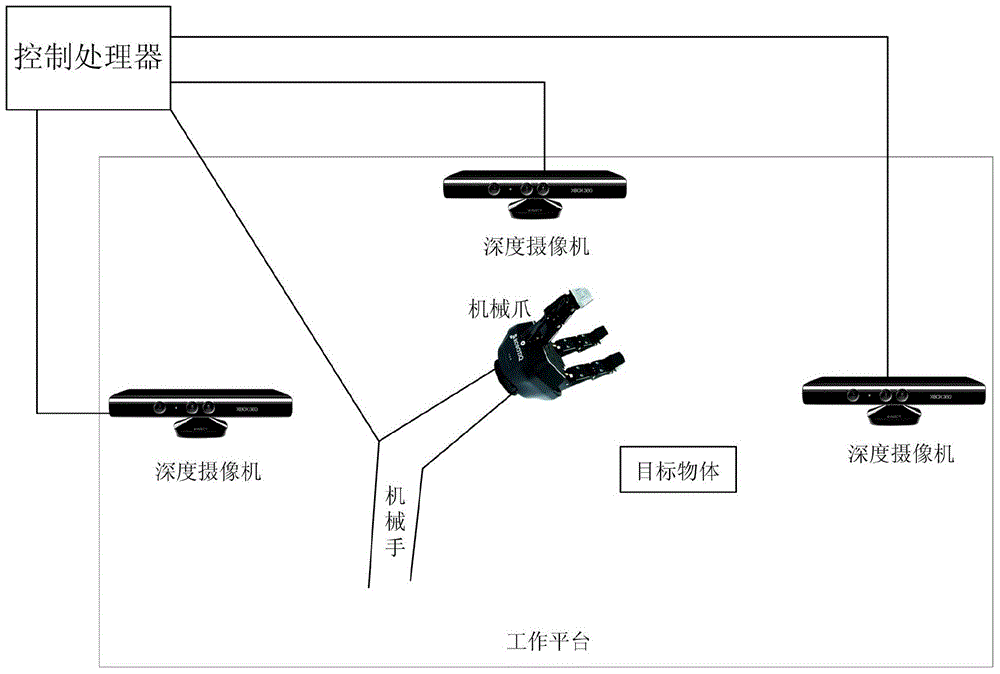

[0028] Such as figure 1 As shown, the present invention is based on a multi-depth camera enhanced robot workbench, including multiple depth cameras, a work platform, a manipulator, a mechanical claw and a control processor, wherein:

[0029] Multiple depth cameras are fixed around the robot, taking three as an example, located at the front and left and right sides respectively, and the depth cameras are used to collect image information of the robot's surrounding environment in real time.

[0030] The control processor recognizes the target object according to the image collected by the depth camera, converts its three-dimensional coordinates in the camera coordinate system into three-dimensional coordinates in the robot coordinate system, and then contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com