A system and method for sorting and packing bulb lamps based on machine vision

A machine vision and vision system technology, applied in manipulators, program-controlled manipulators, chucks, etc., can solve the problems of high manufacturing cost, complex structure, inconvenient installation, etc., and achieve the effect of ensuring photographing quality, high operating efficiency, and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] In order to enable those skilled in the art to better understand the technical solution of the present invention, the product of the present invention will be further described in detail below in conjunction with the embodiments and accompanying drawings.

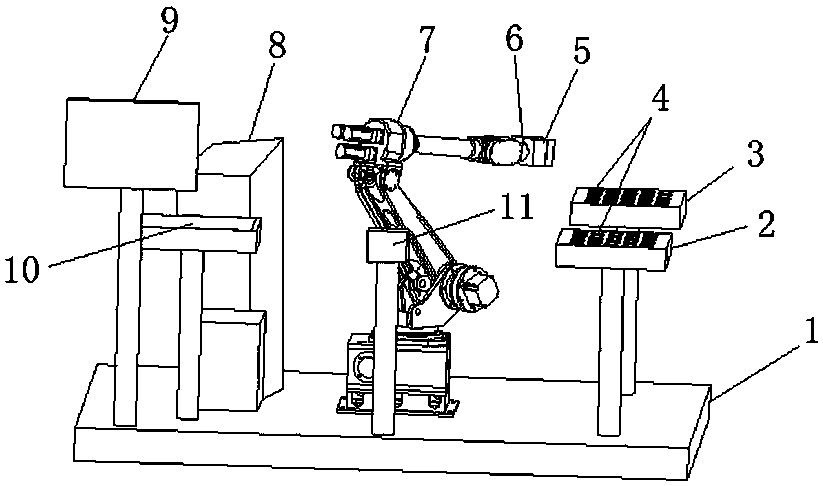

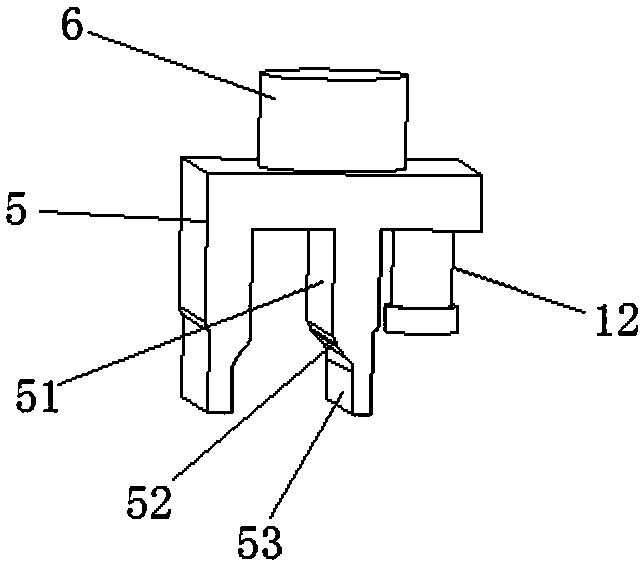

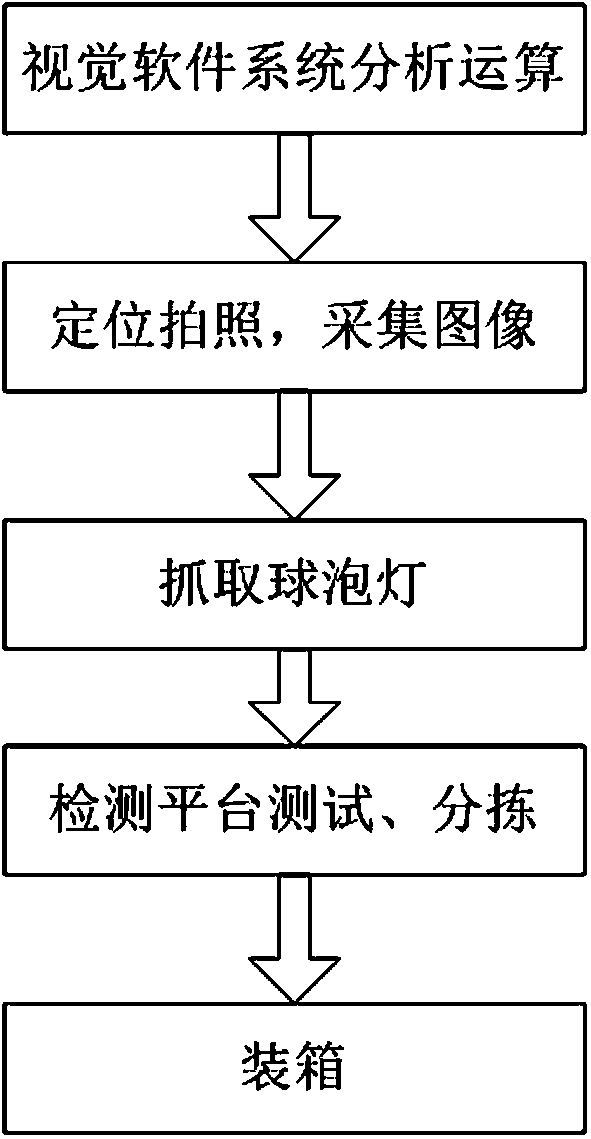

[0032] like figure 1 and figure 2 As shown, a bulb lamp sorting and packing system based on machine vision includes a working platform 1, on which a robot module, a vision system module and a workpiece platform module are arranged, and the robot module includes a six-axis Robot 7, manipulator claw 5 and PLC control box 8, described manipulator claw 5 is installed on the rotating manipulator 6 of six-axis robot 7 ends, and described six-axis robot 7 and manipulator claw 5 are connected with PLC control box 8 respectively; The workpiece platform module includes a camera area platform 10 for placing the bulb lamp to be detected, a detection platform 11 for testing whether the bulb lamp is good, a finished product box ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com