Drying system and clothes drying device

A drying system and throttling device technology, which is applied in washing devices, household dryers, textiles and papermaking, etc., can solve problems such as accumulation, complex pipeline design, and condensed water cannot be discharged smoothly, so as to reduce volume and drain water good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

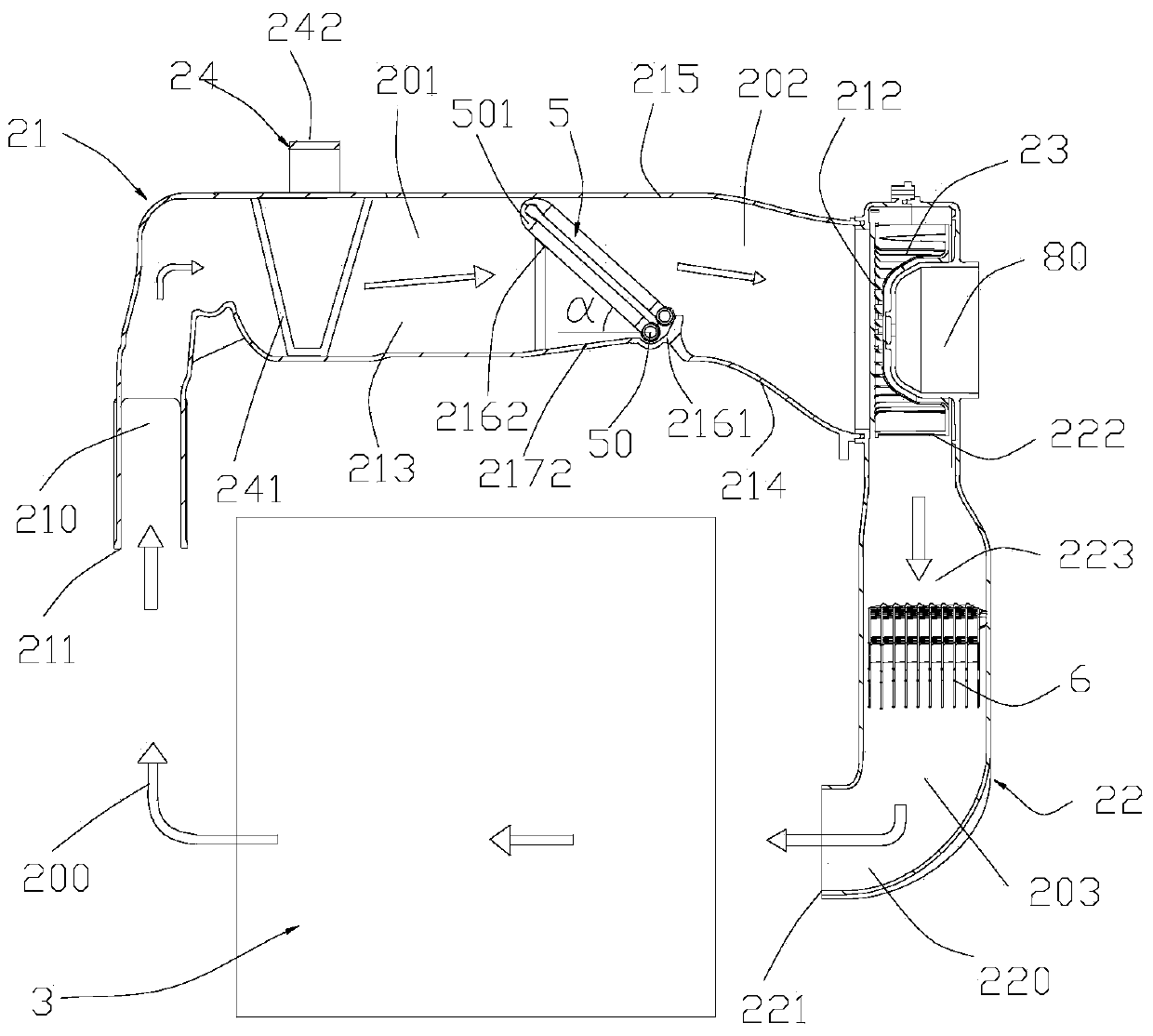

[0023] The following is an exemplary embodiment of a heat pump clothes drying device. The drawings are only schematic and should not be regarded as limitations on the embodiment of the invention. For example, the fins of the heat exchanger are only partially schematic but not fully drawn.

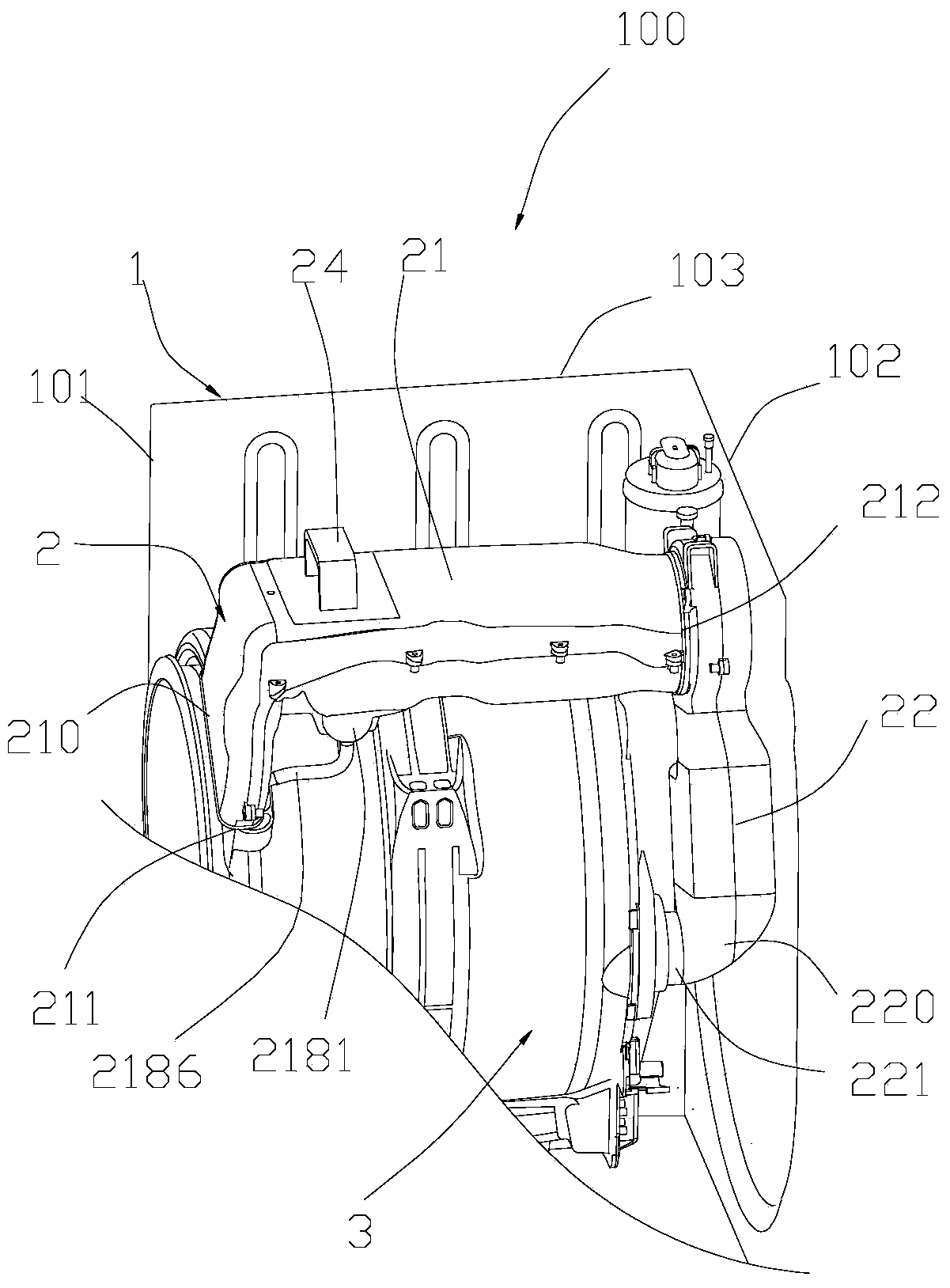

[0024] Hereinafter, specific description will be made with reference to a drum-type washer-dryer or clothes dryer as an example. Please refer to Figure 1 to Figure 3 As shown, the first embodiment of the present invention discloses a washing and drying machine 100, which includes a box body 1, a drying system 2 and a drum 3 installed in the box body 1, and the box body 1 includes a door opening The front portion 101, the rear portion 102 opposite to the front portion, and the side portions 103 located on the left and right sides of the front and rear portion.

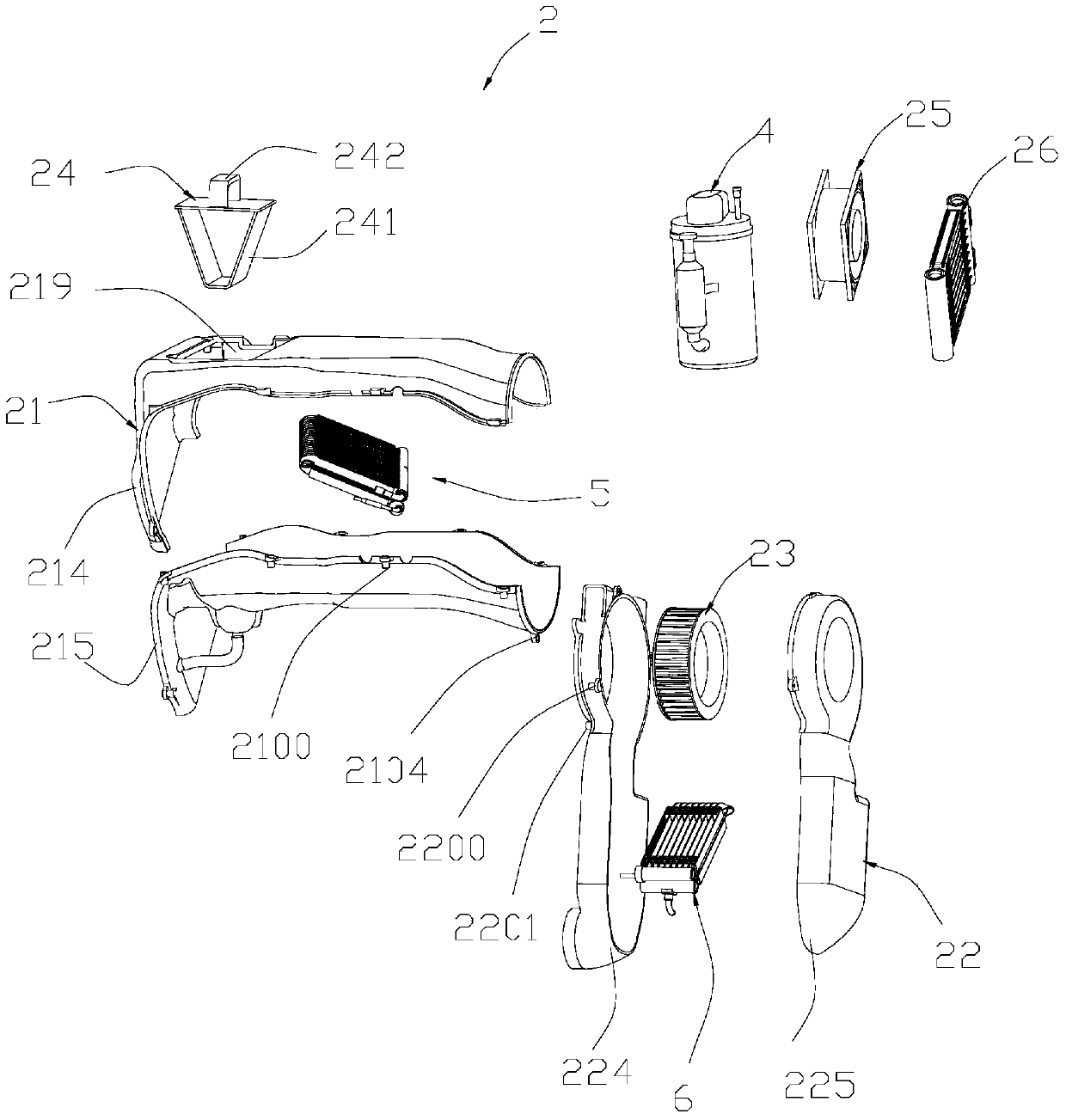

[0025] The drying system 2 includes a first casing 21 arranged roughly horizontally, a second casing 22 assembled on the first ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com