A cold and hot air conditioner with oil-free circulating pipeline

A circulation pipeline and air conditioner technology, which is applied to fluid circulation arrangements, refrigerators, refrigeration components, etc., can solve problems such as increased compressor power consumption, compressor inoperability, and reduced refrigerant displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] Example 1: A cold and hot air conditioner with oil-free circulating pipeline (air conditioner with four-way valve omitted)

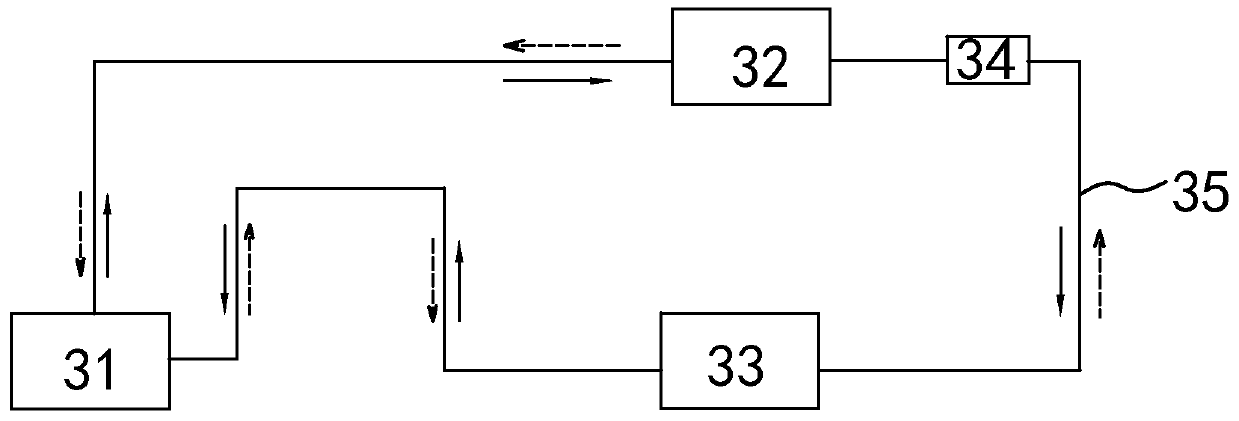

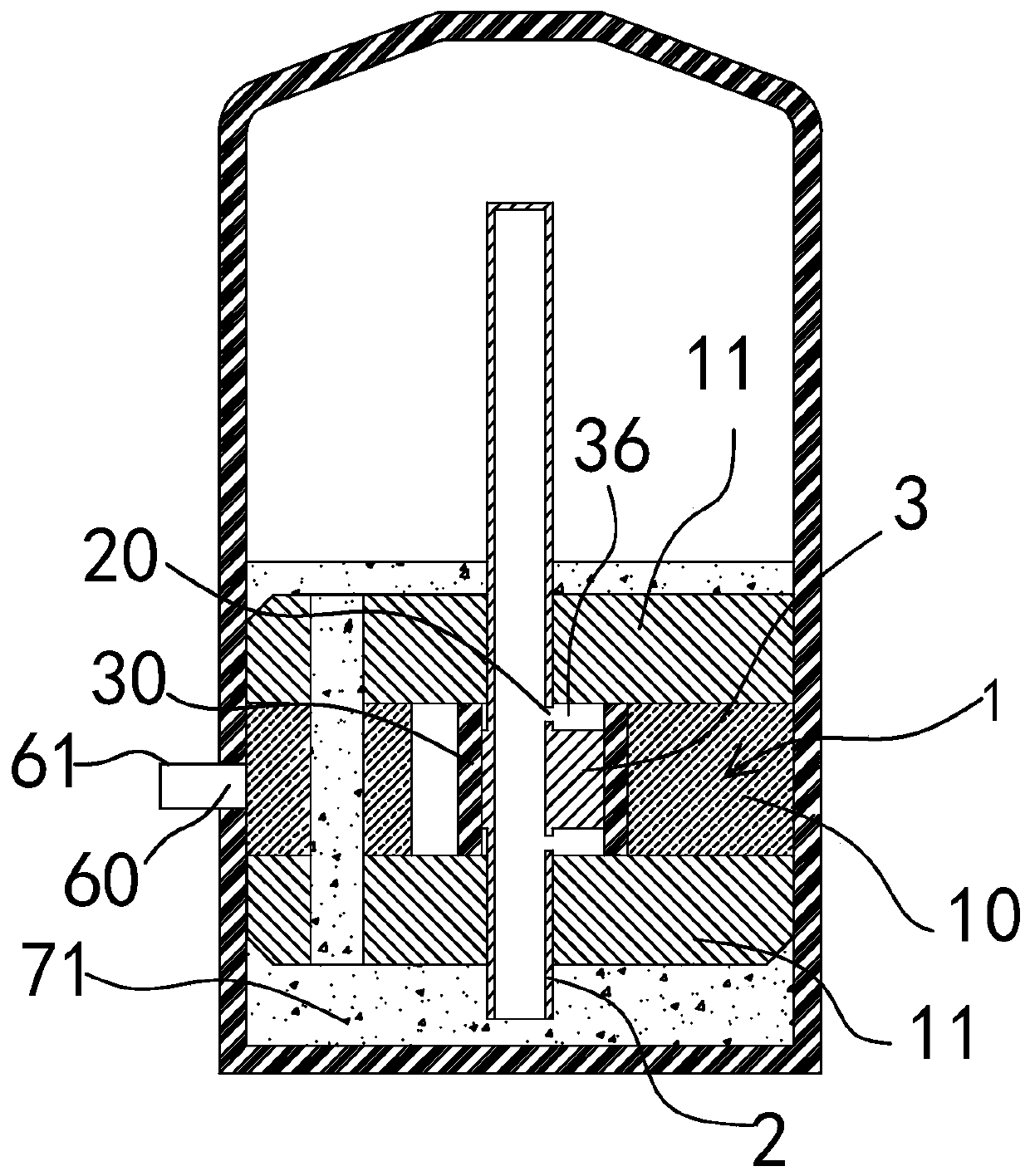

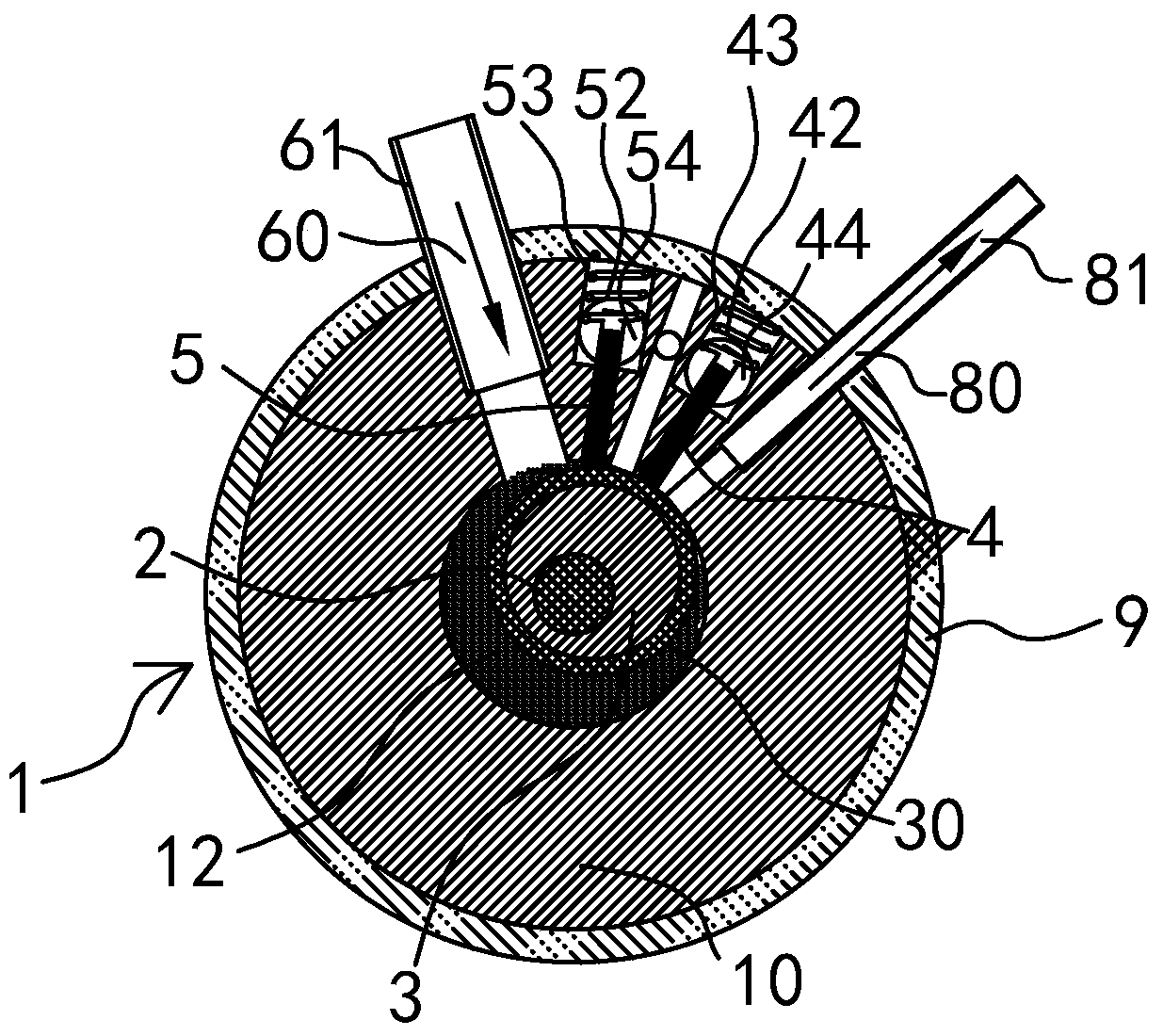

[0066] See attached figure 1 , attached Figure 3-5 , attached Figure 7 , The hot and cold air conditioner has a compressor, a condenser 32 , a throttle 34 , an evaporator 33 and a pipeline 35 . Wherein, the compressor is an oil-gas separation compressor 31, which is composed of a driving motor (not shown in the figure) and a compression device connected to the driving motor. The cooling and heating circulation loop is composed of an oil-gas separation compressor 31 , a condenser 32 , a throttling device 34 , and an evaporator 33 connected in sequence through the pipeline 35 .

[0067] The driving motor has two working states of forward rotation and reverse rotation. When the driving motor is rotating forward, the cooling and heating cycle circuit realizes refrigeration cycle work, and when the driving motor rotates reversely, the cooling and ...

Embodiment 2

[0083] Example 2: A circulating pipeline oil-free cold and hot air conditioner (air conditioner with a four-way valve)

[0084] See attached Figure 9 , the rest are the same as in Embodiment 1, except that the hot and cold air conditioner has a four-way valve 37. The cooling and heating circulation circuit is composed of an oil-gas separation compressor 31 , a four-way valve 37 , a condenser 32 , a throttling device 34 , and an evaporator 33 sequentially connected through the pipeline 35 . When the driving motor rotates, the cooling and heating cycle circuit realizes cooling or heating cycle through the switching of the four-way valve 37 .

[0085] The cooling and heating air conditioner with no oil in the circulating pipeline of this embodiment significantly improves the heat exchange efficiency of the air conditioner and significantly improves the energy efficiency ratio of the air conditioner because no lubricating oil participates in the system circulation. The oil-gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com