Temperature regulating fan and control method thereof

A technology of temperature regulation and control method, which is applied in heating and ventilation control system, control input related to air characteristics, space heating and ventilation control input, etc. Poor effect and other problems, to achieve high-efficiency cooling and heating efficiency, high cooling efficiency, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

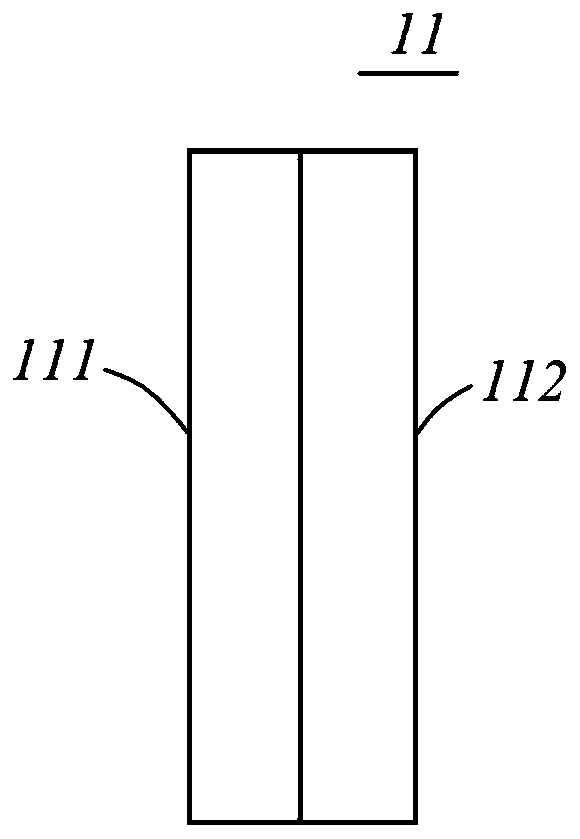

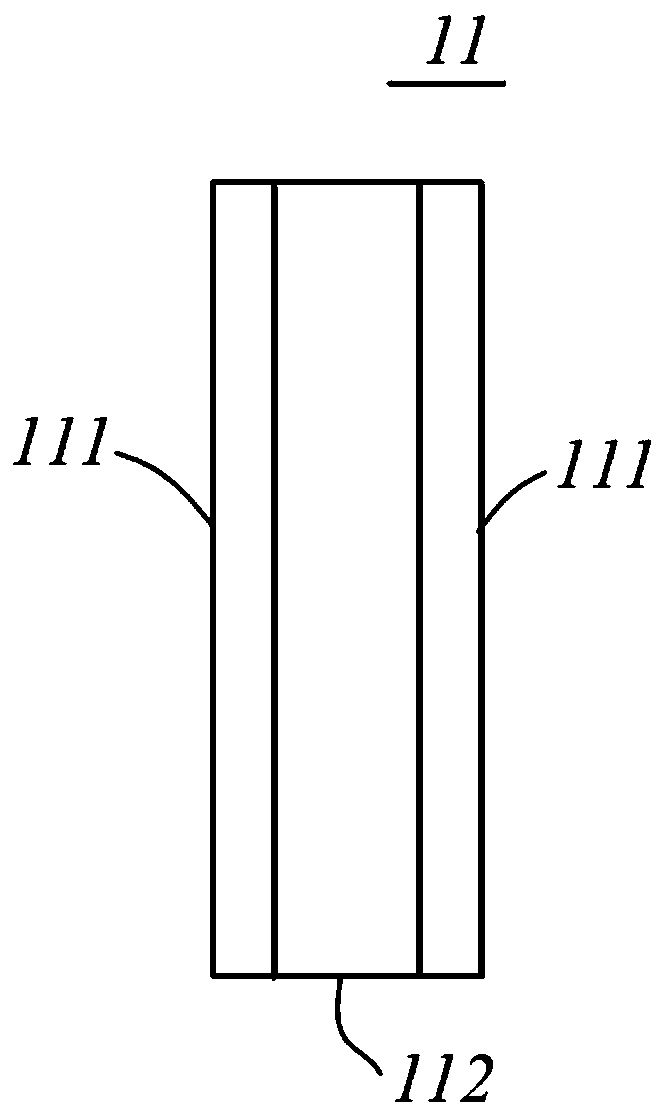

[0090] ginseng Figure 6 , the temperature regulating fan 100a includes a casing, a wet curtain assembly, and an airflow driving assembly 71a. At least part of the evaporation unit 11a of the wet curtain assembly is made of metal, specifically, the evaporation unit 11a can be metal honeycomb paper, the honeycomb paper has a porous honeycomb array structure, has a higher specific surface area, and significantly increases the evaporation area. Thereby further improving the heat exchange efficiency.

[0091] Similarly, the evaporation unit can also include metal honeycomb paper and paper honeycomb paper composited with each other. The number of composite layers and composite forms of metal honeycomb paper and paper honeycomb paper can be selected according to actual needs, with a three-layer composite structure as the For example, it may be metal honeycomb paper, paper honeycomb paper, and metal honeycomb paper that are sequentially composited; or, paper honeycomb paper, metal h...

Embodiment 2

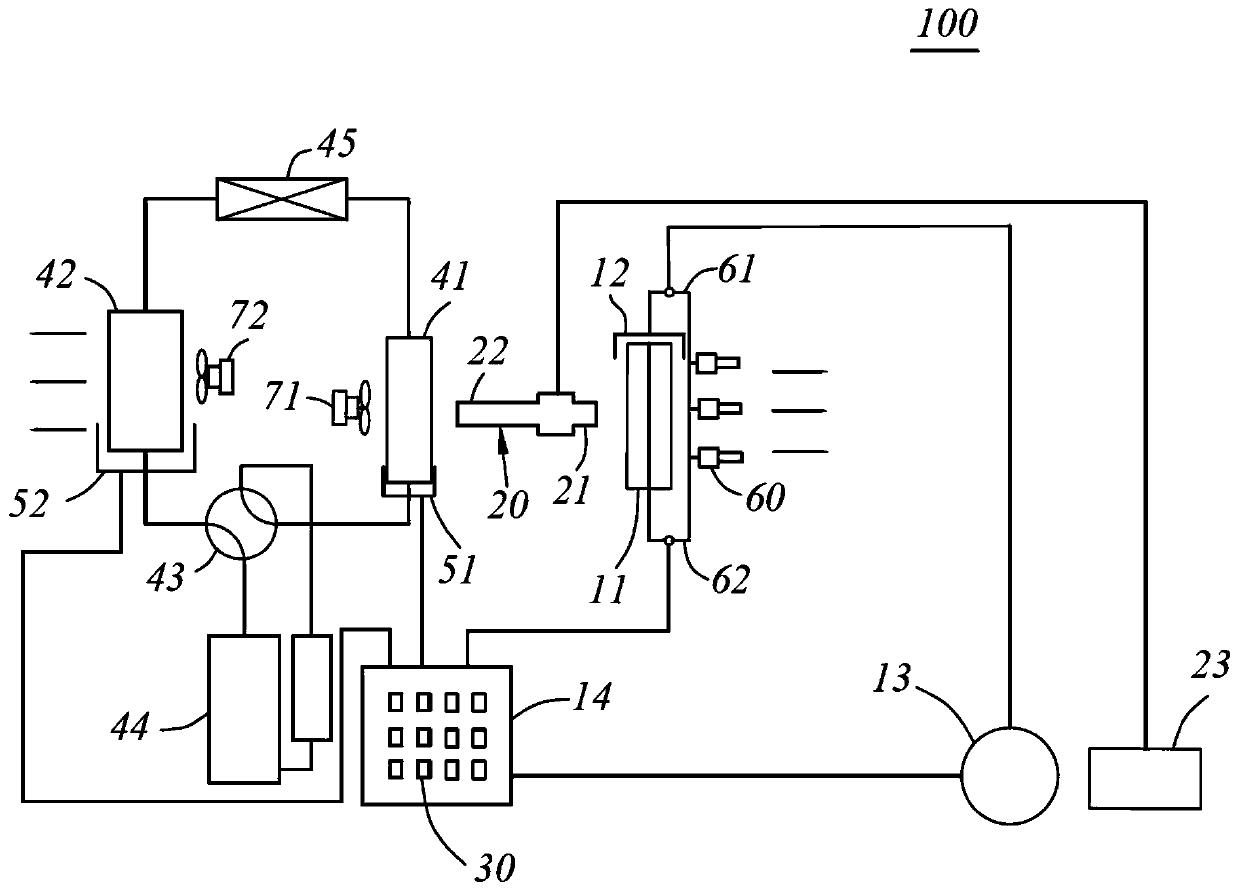

[0094] ginseng Figure 7 and Figure 8 The temperature regulating fan 100b includes a housing, a wet curtain assembly, a vortex cooling assembly 20b, and an airflow driving assembly 71b. The vortex cooling assembly 20b includes a vortex cooling tube, and the vortex cooling tube can at least send the airflow blown out from the cold end 21b or the hot end 22b into the airflow channel in a controlled manner. The number of vortex cooling tubes can be set to one or more according to needs, and the vortex cooling assembly 20b also includes an air compressor 23b in gas communication with the vortex cooling tubes, and the air compressor is used to provide compressed air for the vortex cooling tubes.

[0095] Figure 7 and Figure 8 What is shown is a schematic diagram of cooperation between different ends of the vortex cooling tube and the exhaust channel, and the air flow at the cold end 21b of the vortex cooling tube can make up for the defect of insufficient cooling efficiency o...

Embodiment 3

[0099] ginseng Figure 9 The temperature regulating fan 100c includes a casing, a wet curtain assembly, a temperature control assembly 30c, and an airflow driving assembly 71c. The temperature control assembly 30c cooperates with the water tank 14c to adjust the temperature of the water stored in the water tank 14c. By adjusting the water storage temperature of the water tank 14c, the cooling and heating efficiency of the temperature regulating fan 100c can be further increased. The temperature control assembly 30c here includes a semiconductor refrigerator. The semiconductor refrigerator can be controlled to make its hot end cooperate with the water tank 14c to heat the stored water in the water tank 14c; of water storage.

[0100] That is to say, this embodiment mainly involves the additional temperature control assembly 30c that cooperates with the water tank, and may not involve others.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com