Oil-gas separation type air-condition compressor

An air-conditioning compressor and a separate technology, applied in the field of air-conditioning compressors, can solve the problems of affecting refrigerant heat exchange, space reduction, occupation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

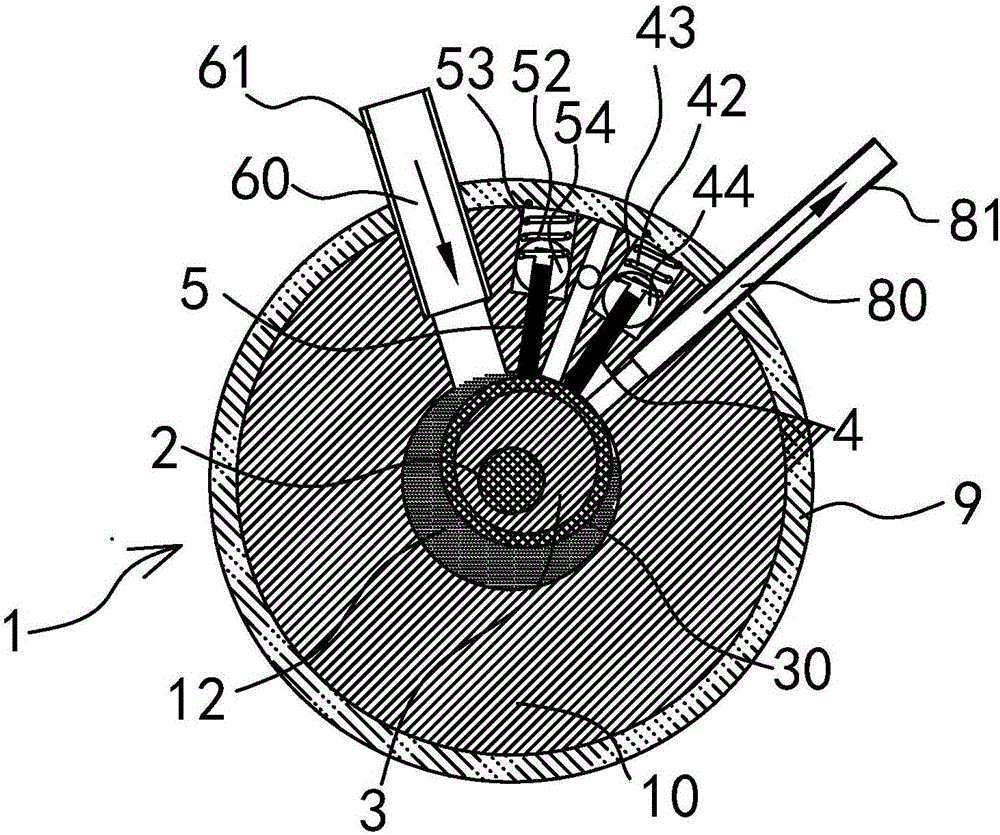

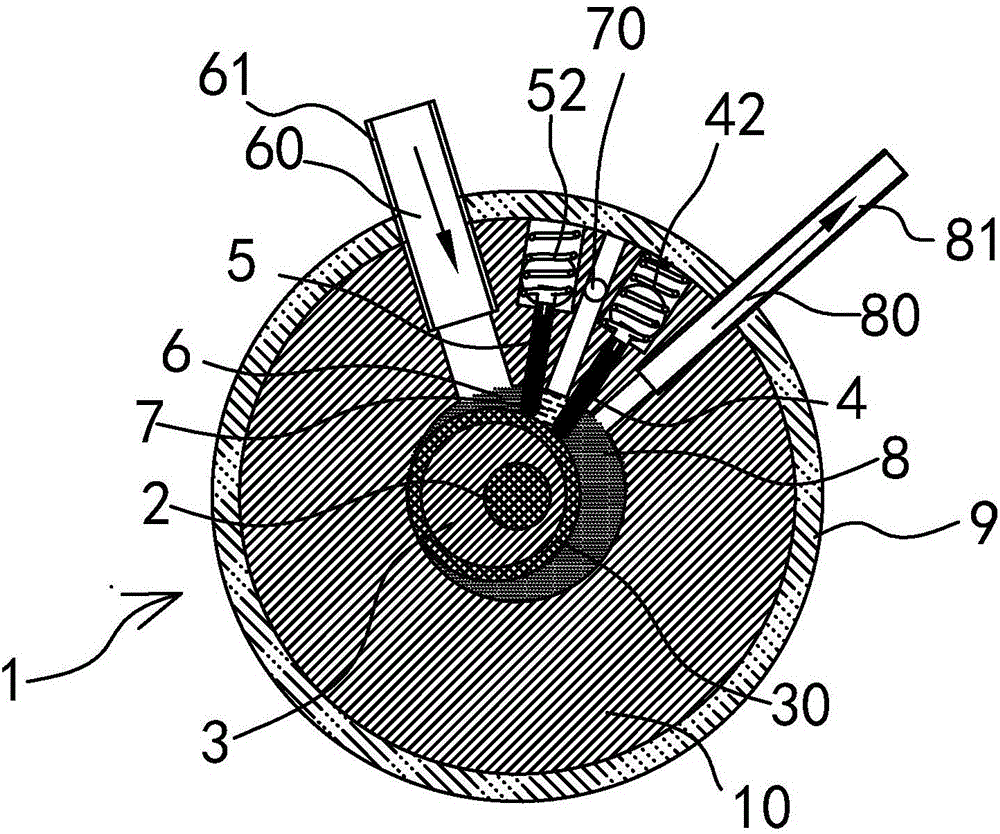

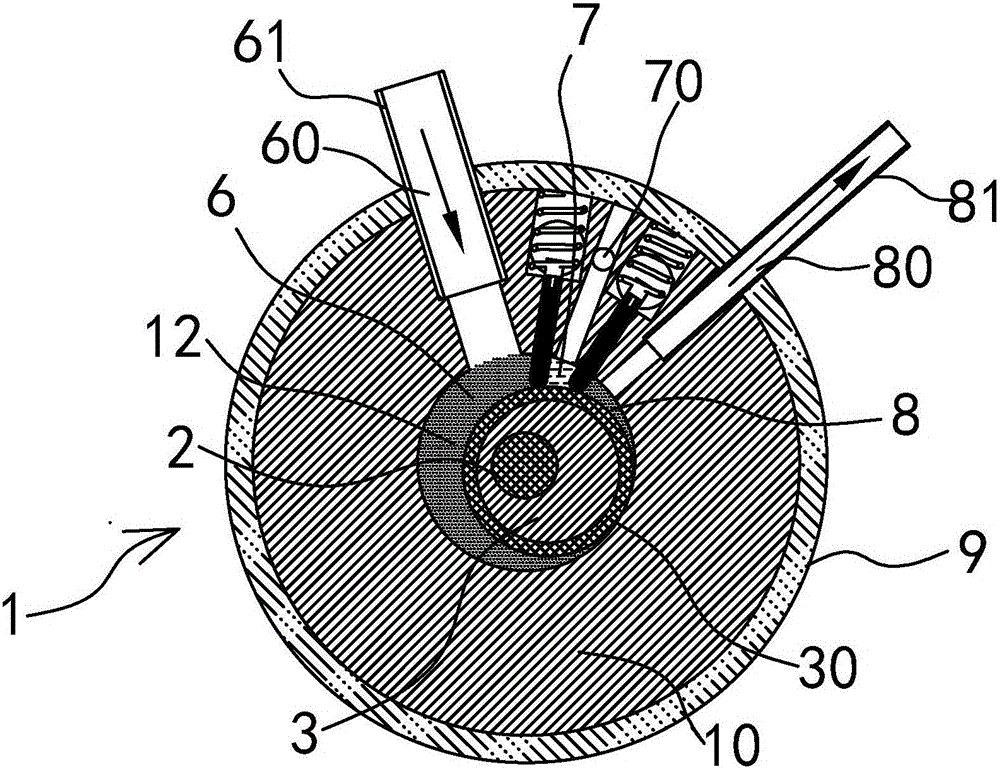

[0055] Example: an oil-gas separation type air conditioner compressor

[0056] See attached Figure 1~3 , attached Figure 5 , an oil-gas separation type air conditioner compressor, including a shell 9, the shell 9 includes: a drive motor, a cylinder 1, a main shaft 2, an eccentric rotor 3, a rotary sleeve 30, a first sliding assembly and a second sliding assembly.

[0057] The main shaft 2 is concentric with the cylinder body 1, and the eccentric rotor 3 is arranged on the outer peripheral surface of the main shaft 2 and is eccentric with the main shaft 2. The output shaft of the drive motor is connected to the main shaft 2 to drive the main shaft 2 to rotate.

[0058] Wherein, the cylinder 1 includes a cylinder body 10 and sealing end caps 11 arranged on the upper and lower ends of the cylinder body 10, the cylinder body 10 and the sealing end caps 11 enclose the entire cylinder space. The lubricating oil storage space 71 is formed between the shell 9 and the cylinder bod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com