Construction method for steel-concrete joint section of bridge

A technology of steel-concrete combination and construction method, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficult adjustment of steel towers, and achieve the effect of solving rough connections, small internal space occupation, and overcoming difficult adjustments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A preferred embodiment will be given below, and the present invention will be described more clearly and completely in conjunction with the accompanying drawings.

[0023] A construction method for a steel-concrete joint section of a bridge, comprising the following steps:

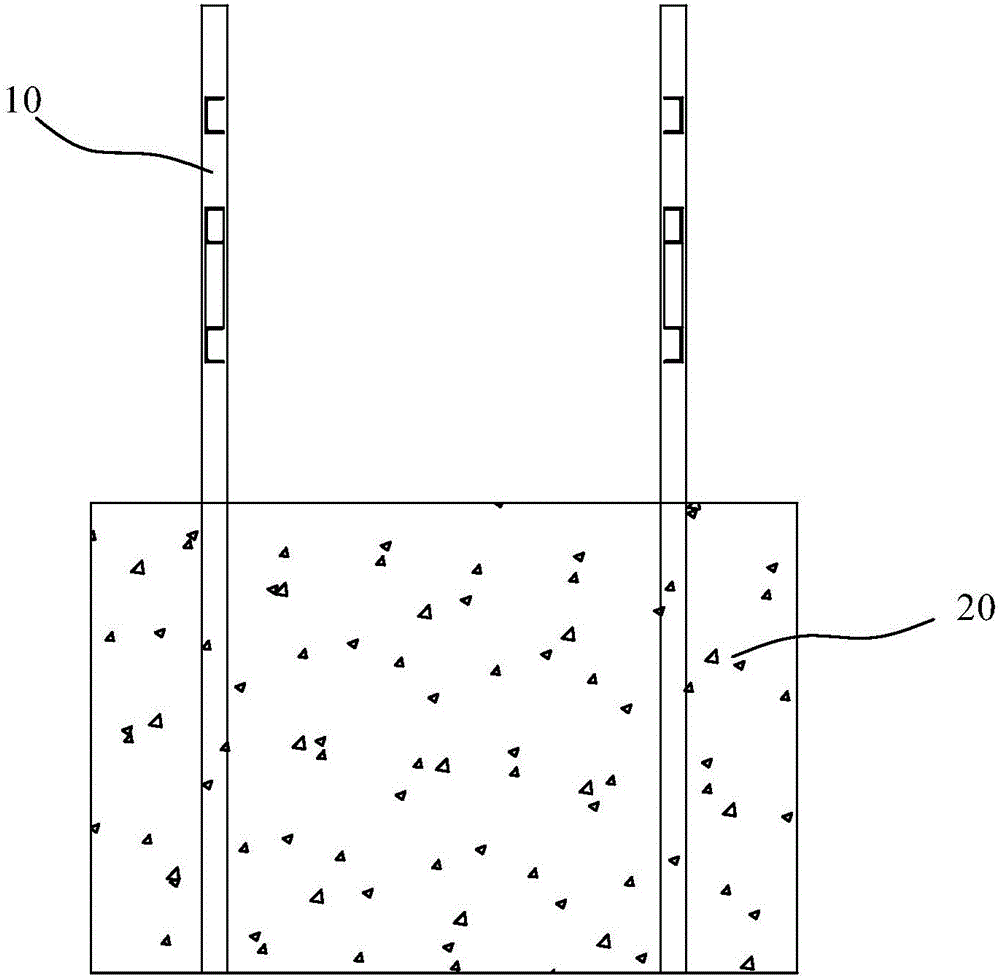

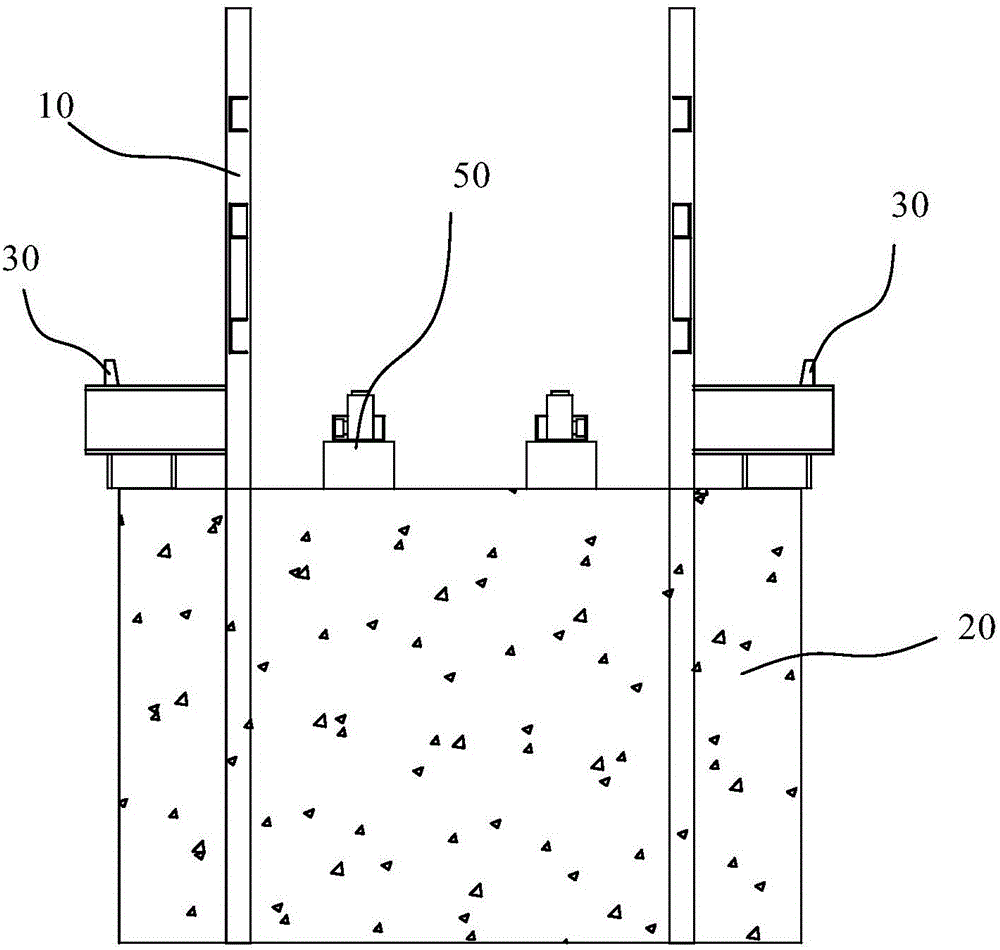

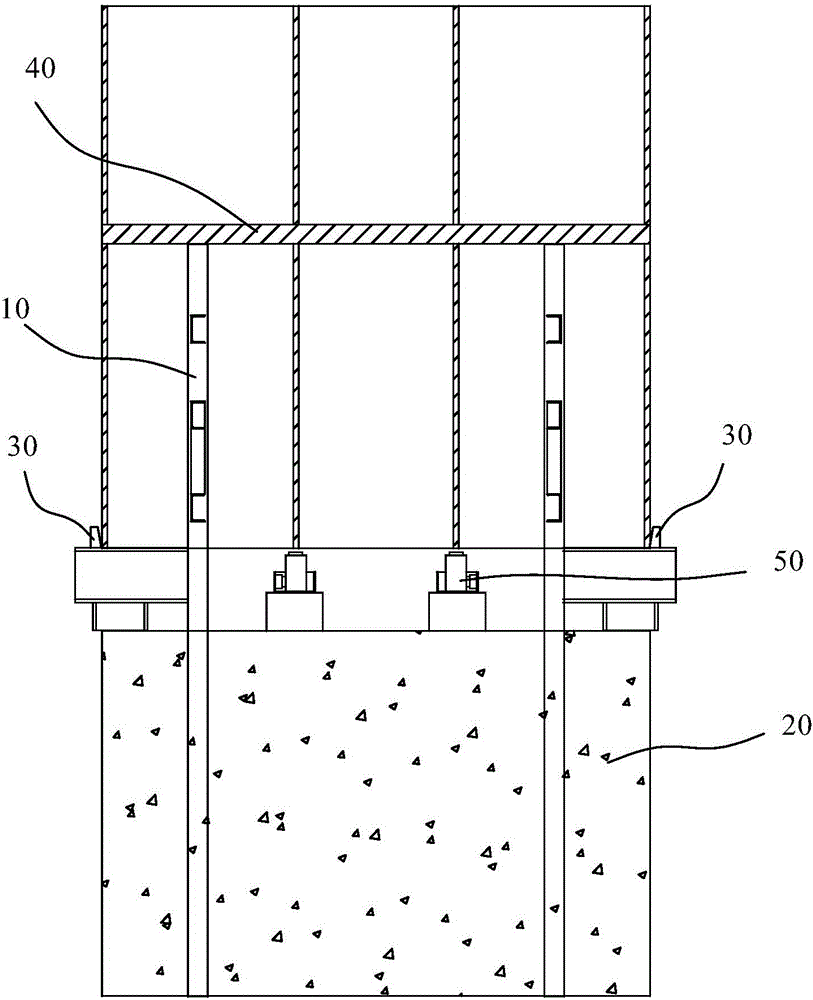

[0024] Step 1, such as figure 1 As shown, the lower part of the inner support frame 10 is embedded in the top of the concrete section 20 of the bridge tower. When binding the steel bars (not shown in the figure) of the concrete section, the lower part of the inner support frame is buried in the concrete section; and then the concrete is poured on the top of the concrete section. In this way, the characteristics of the concrete structure can be fully utilized to transfer loads; materials are saved, and the economy is outstanding; the implementation is simple and convenient; the impact on the appearance of the structure is small, and the construction quality can be better guaranteed. The inner suppo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com