A prefabricated building folding throwing net and its installation method

A prefabricated and foldable technology, applied in construction, building structure, processing of building materials, etc., can solve the problems of high cost, complicated installation procedures of protective throwing nets, and a lot of labor, so as to achieve easy disassembly and assembly, and solve the installation procedures. Sophisticated, material and time-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

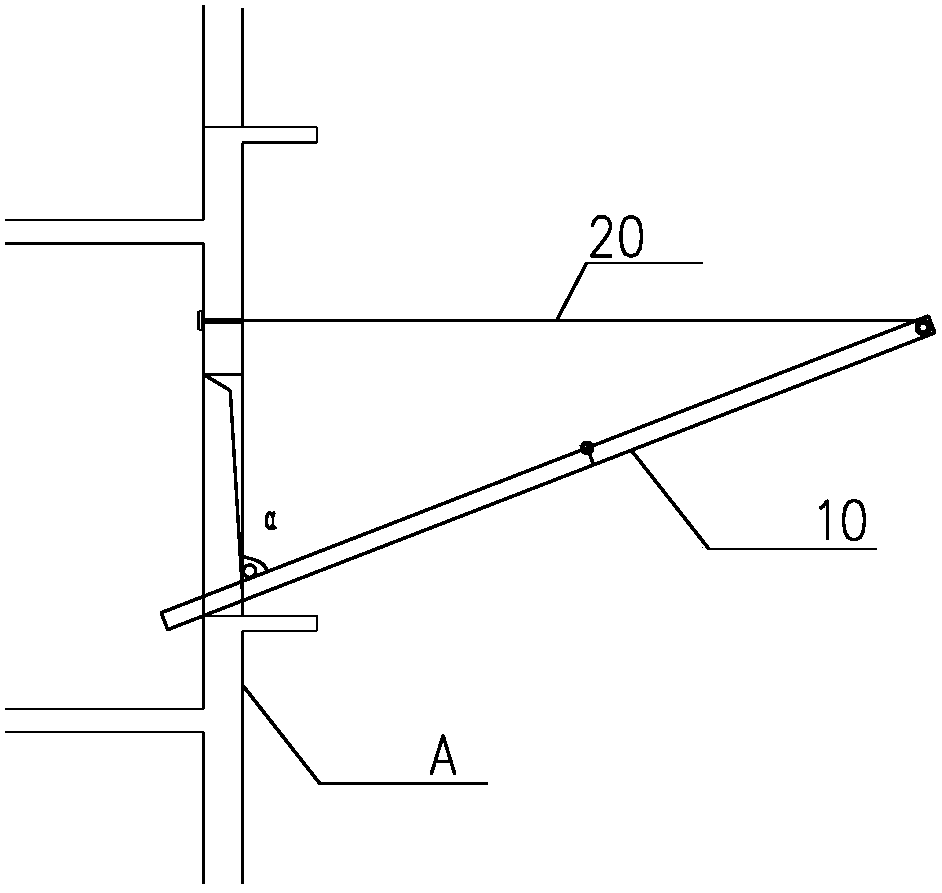

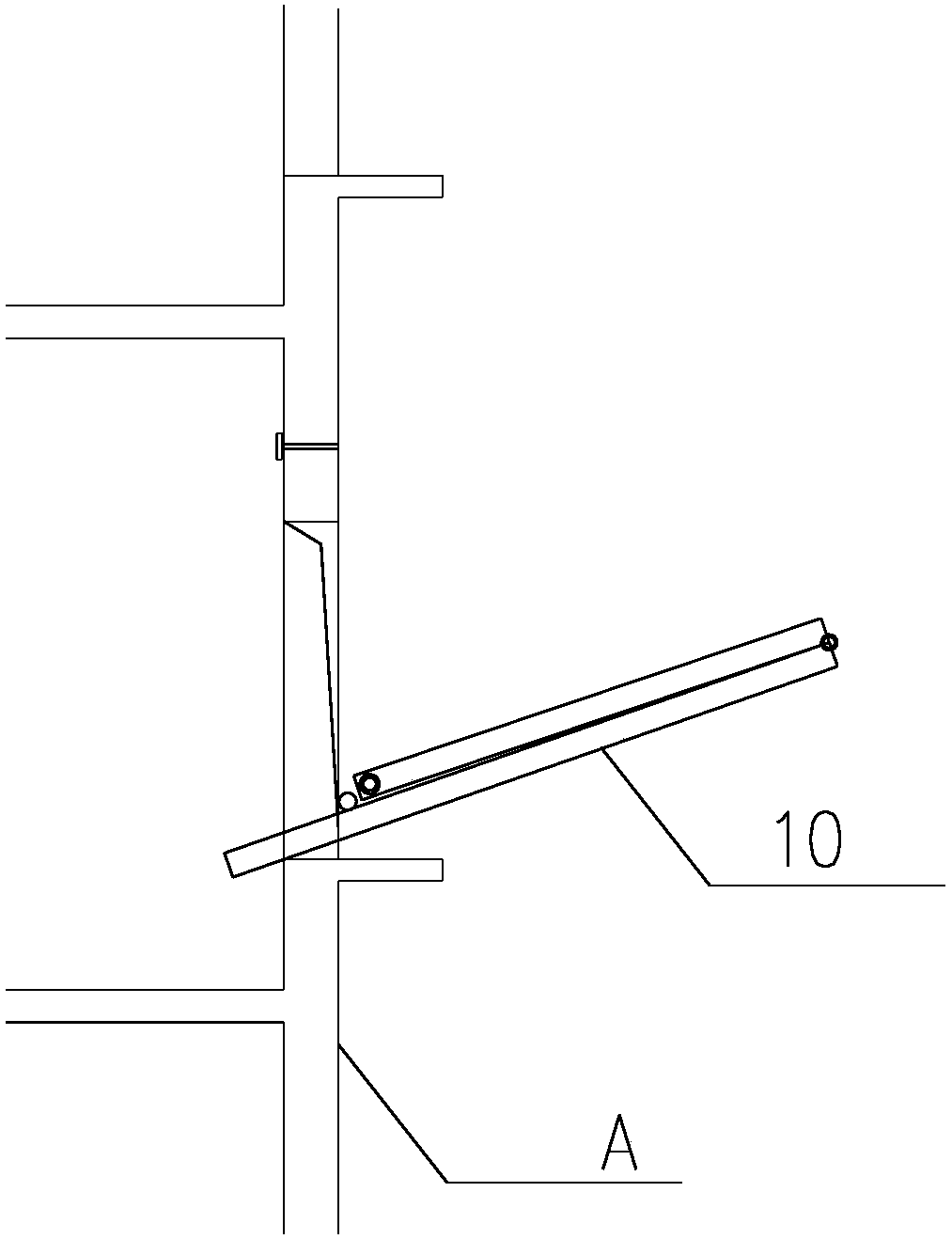

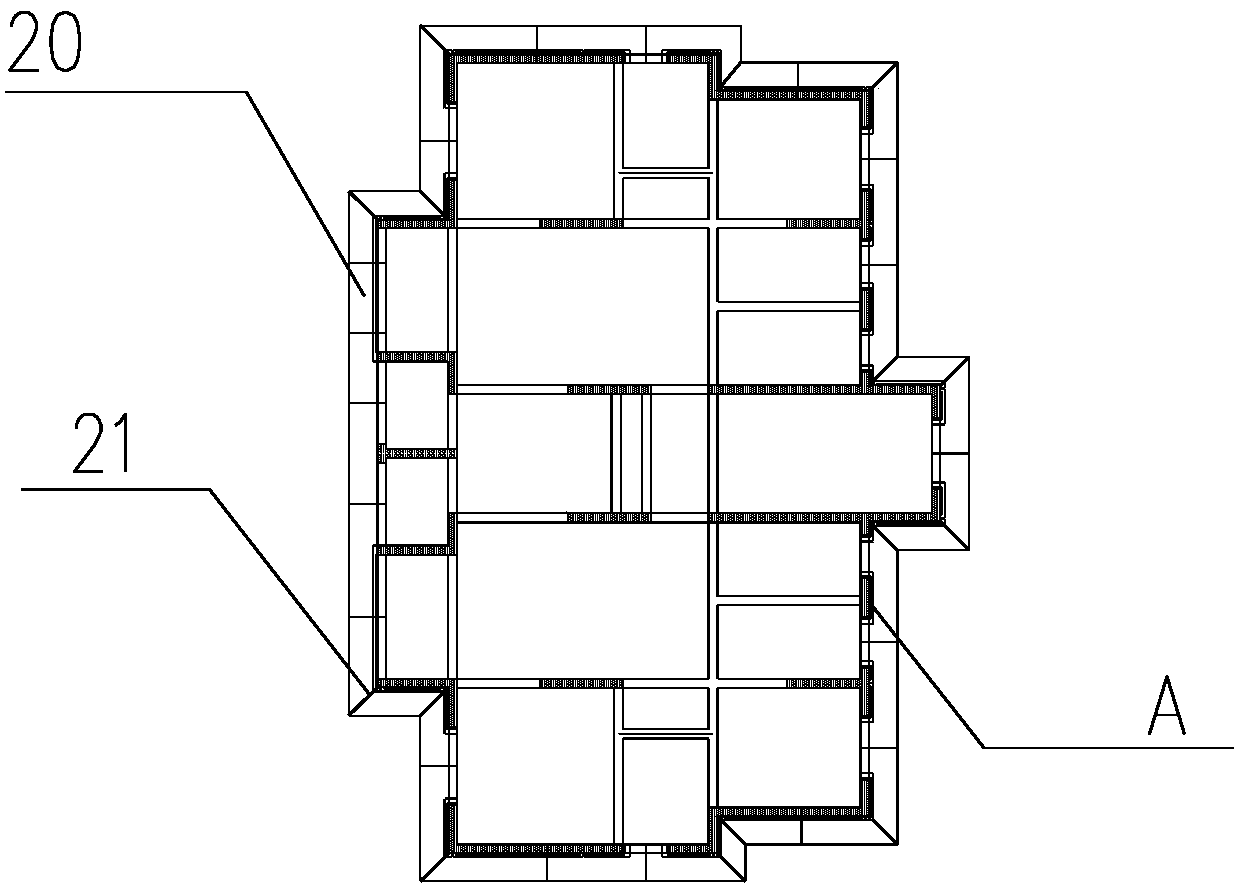

[0028] refer to Figure 1 to Figure 3 Describe in detail the prefabricated building folding throwing net and installation method of the present invention. A prefabricated and assembled building folding throwing net, which is arranged close to the outer wall A of the prefabricated and assembled building from bottom to top according to a certain interval. The cantilever rods 10 are spliced in parallel at intervals, and the cantilever rods are formed by two sections of standard rods connected vertically and sequentially; the net body 20, the net body 20 is laid on the upper surface of the horizontal frame, and the surroundings of the net body 20 and the horizontal The surroundings of the frame body are fixedly connected, and the cantilevered rods 10 are connected into one; the angle between the horizontal frame body and the exterior wall A of the prefabricated building is α, 70°≤α≤80°, so that the cantilevered rods 10 are close to The standard rod at the free end can be folded...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com