A particle size control method of superparamagnetic iron oxide microspheres

A technology of superparamagnetic iron oxide and microspheres, applied in the direction of iron oxide, iron oxide/iron hydroxide, nanotechnology for materials and surface science, etc., can solve problems such as complex methods, and achieve simple operation and practicability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Weigh 0.14 g (2 mmol) of polyacrylic acid and 0.16 g (1 mmol) of anhydrous ferric chloride and dissolve them in 12 mL of ethylene glycol, stir to form a transparent solution, then add 3 mL of 3-aminopropanol dropwise under stirring , then add 20 μL of ionic liquid 1-ethyl-3-methylimidazolium tetrafluoroborate, mix evenly, transfer to a hydrothermal synthesis reactor (20 mL) with polytetrafluoroethylene liner, seal it, and dry it in the air Keep the temperature in the box at 200°C for 6 h, and cool to room temperature with the furnace to obtain a black sol, add water to dilute, wash with the aid of a magnet to remove impurities, and vacuum dry to obtain a black powder.

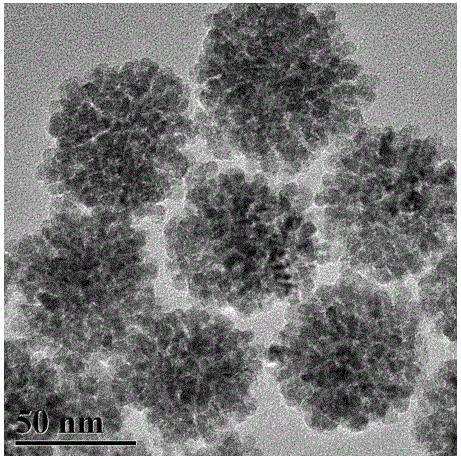

[0027] The electron microscope photograph of the obtained product is as follows figure 1 As shown, the average particle size of the microspheres is 63 nm.

Embodiment 2

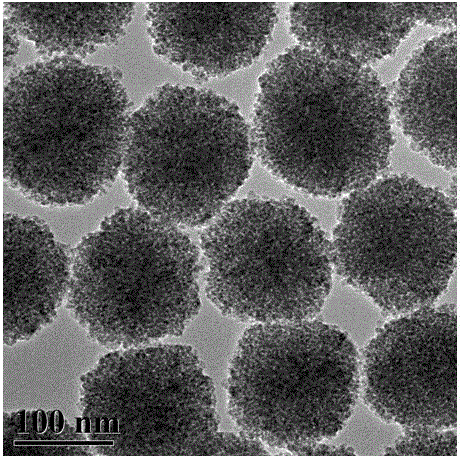

[0029] The method is the same as in Example 1, the volume of the ionic liquid added is 10 μL, and the electron micrograph of the resulting product is as follows: figure 2 As shown, the average particle size of the microspheres is 122 nm.

Embodiment 3

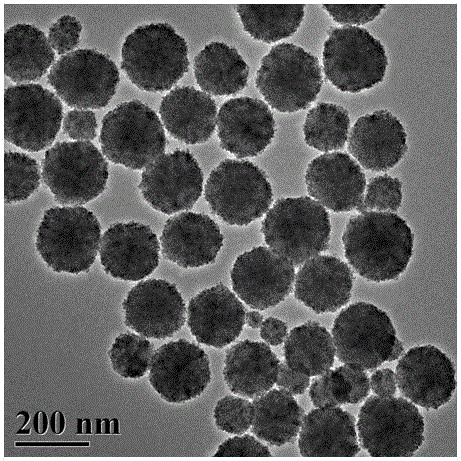

[0031] The method is the same as in Example 1, the volume of the ionic liquid added is 5 μL, and the electron micrograph of the resulting product is as follows: image 3 As shown, the average particle size of the microspheres is 165 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com