Horizontal bidirectional visco elastic collision tuned mass damper system and working method thereof

A technology of tuning mass damping and viscoelasticity, which is applied to building components, building structures, and earthquake resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

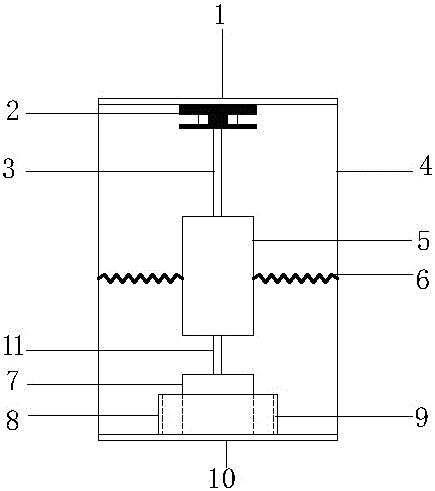

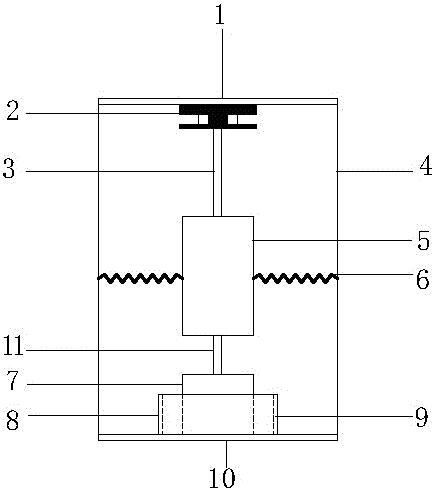

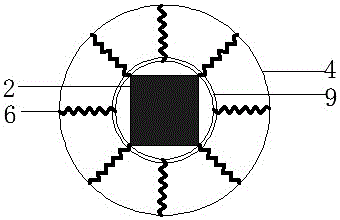

[0026] The technical solution of the present invention will be specifically described below in conjunction with the accompanying drawings.

[0027] A horizontal two-way viscoelastic collision tuned mass damper system of the present invention comprises a hollow circular outer cylinder, an upper cover plate arranged above the hollow circular outer cylinder and a lower cover plate arranged below the hollow circular outer cylinder. A universal hinge is provided at the middle part of the lower end surface of the upper cover plate, and a circular viscoelastic stop device is provided at the middle part of the upper end surface of the lower cover plate, which also includes first and second cylindrical mass blocks, and the first The center of the upper end of a cylindrical mass is hinged to the universal hinge through a first rigid rod, and the center of the lower end of the first cylindrical mass is connected to the center of the upper end of the second cylindrical mass through a secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com