Improved fastening screw

A technology for fastening screws and screws, applied in the direction of screws, threaded fasteners, locking fasteners, etc., can solve problems such as loosening, inconvenience in life, glue overflow, etc., and achieve novel and reasonable screw structure, simple and convenient operation, The effect of long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

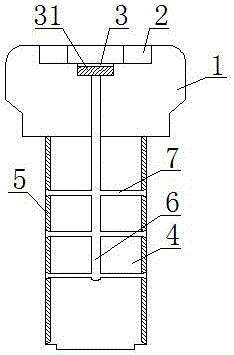

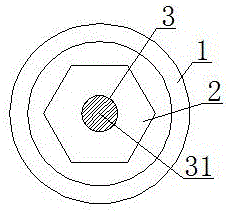

[0018] like figure 1 and figure 2 As shown, an improved fastening screw includes a screw body 4, the top of the screw body 4 is provided with a nut 1, the center of the upper surface of the nut 1 is provided with an inner hexagonal hole 2, and the bottom center of the inner hexagonal hole 2 is provided with Groove 3, there is a matching gasket 31 in the groove 3, the bottom center of the groove 3 is provided with a main channel 6, the bottom of the main channel 6 extends into the screw body 4, and the side of the screw body 4 is provided with an outer In the thread 5 , a plurality of transverse branches 7 are symmetrically arranged on both sides of the main channel 6 .

[0019] In this embodiment, the number of the transverse branches 7 is reasonably adjusted according to the length of the screw body 4, and the optimal number is 4 or 6 or 8. When in use, first use an Allen wrench to rotate the screw body 4 into the component, then pass the glue injection needle through the ...

Embodiment 2

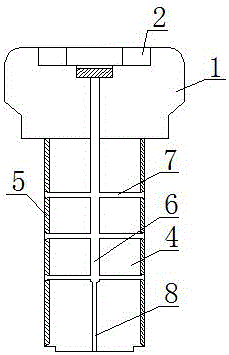

[0021] like image 3 As shown, in this embodiment, on the basis of the first embodiment, a longitudinal branch 8 is arranged in the center of the bottom of the main channel 6, and the bottom of the longitudinal branch 8 is flush with the bottom of the screw body 4, so that the bottom of the screw body 4 and the components The screws are also fastened with glue to further improve the tightness of the screws.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com