Curved surface touch device and method for manufacturing same

A touch device and touch surface technology, applied in the input/output process of data processing, instruments, electrical digital data processing, etc., to achieve the effect of meeting diversified needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

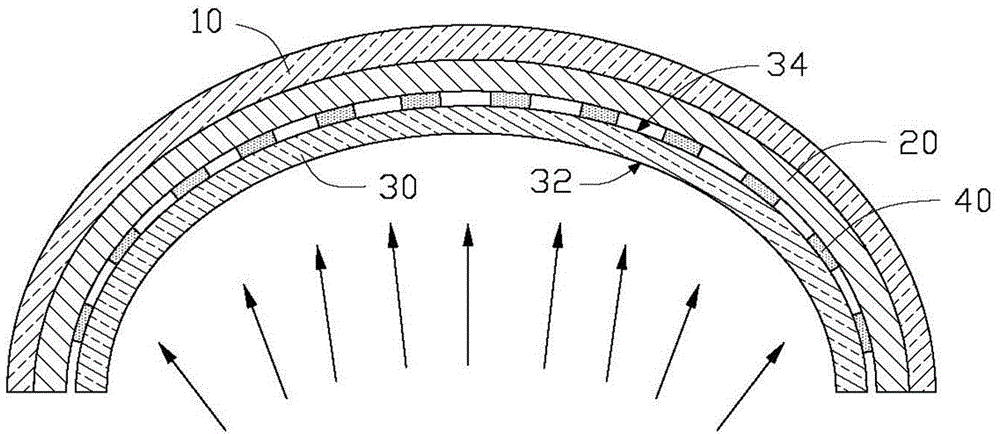

[0014] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

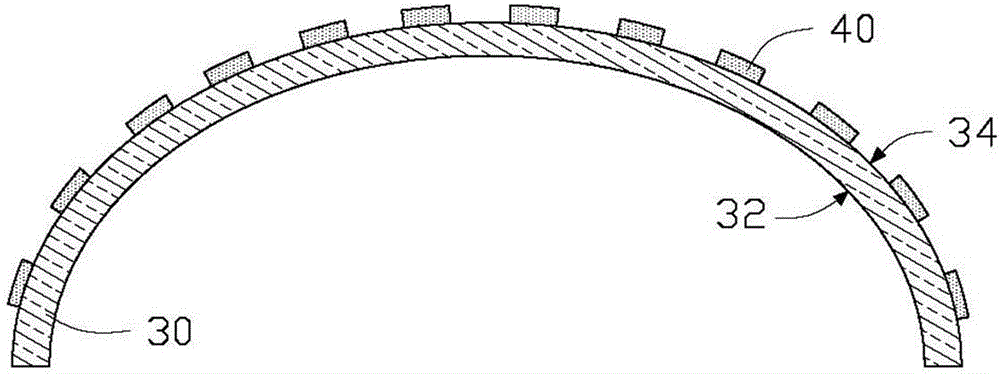

[0015] Please refer to Figure 1 to Figure 4 , Is a method for manufacturing the curved touch device 100 provided by the embodiment of the present invention.

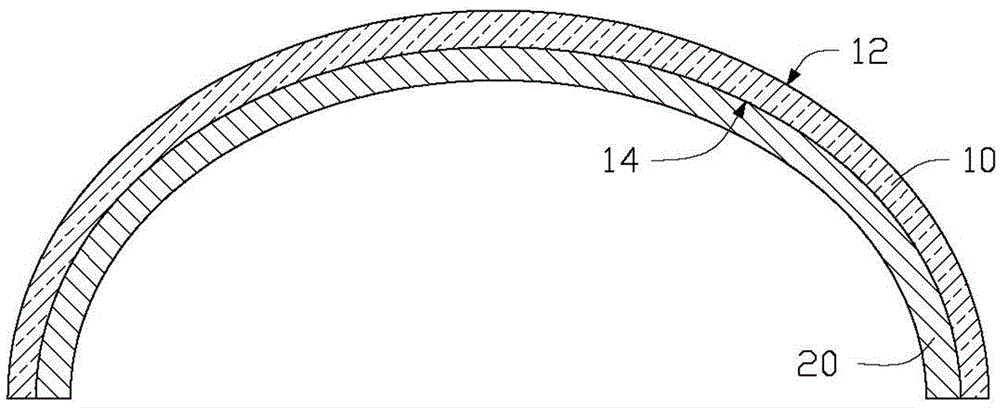

[0016] See figure 1 , The first step is to provide a transparent workpiece 10. The workpiece 10 is approximately in the shape of a curved arch bridge. The workpiece 10 includes a touch surface 12 and a molding surface 14. The touch surface 12 and the molding surface 14 are located on opposite sides of the workpiece 10. The touch surface 12 protrudes outward. Both the molding surface 14 and the touch surface 12 are arc-shaped. The workpiece 10 is made of transparent materials such as glass or acrylic.

[0017] See figure 1 In the second step, a layer of conductive material 20 with a uniform thickness is plated on the molding surface 14. The shape of the conductive material layer 20 is...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap