Method for synthesizing for non-probability time-varying reliability of link mechanism containing hinge gap

A technology of hinge clearance and comprehensive method, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve the problems of time-varying reliability, inability to obtain sample information, ignoring free movement of shaft pins, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

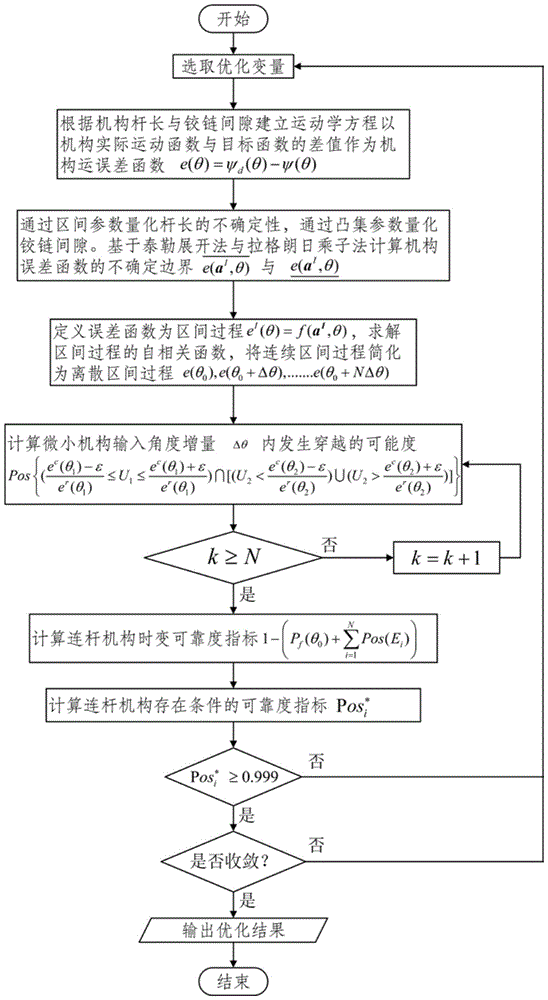

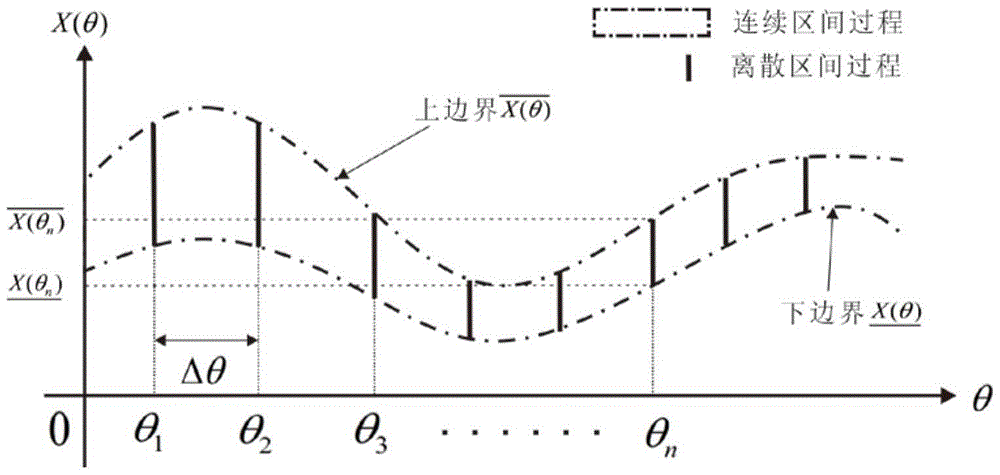

Method used

Image

Examples

Embodiment

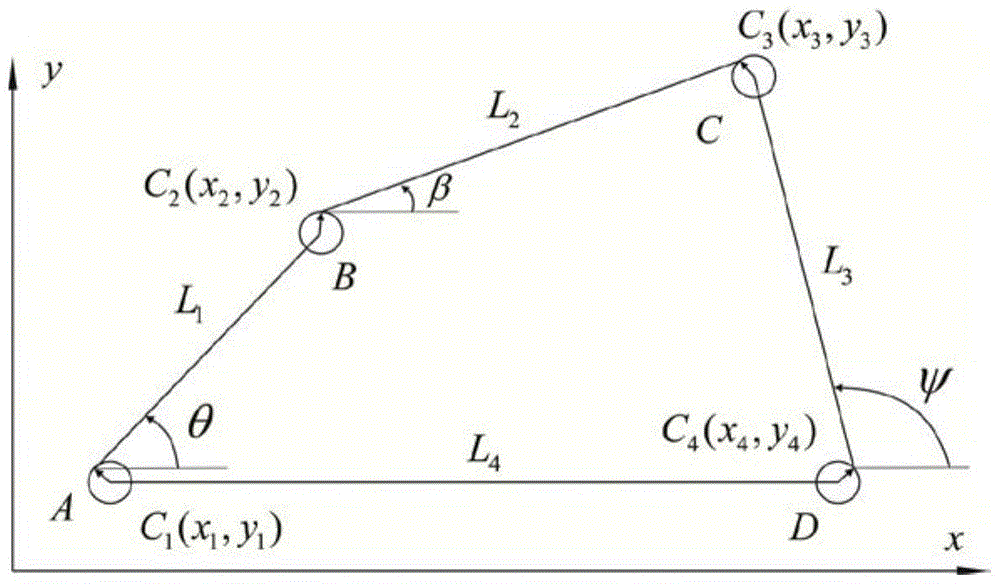

[0133] In order to understand more fully the characteristics of the invention and its applicability to engineering practice, the present invention aims at figure 2 The shown four-link equation generation mechanism performs the non-probabilistic time-varying reliability synthesis proposed by the present invention and the traditional static reliability synthesis. The institutional objective function is y=arctan(x), where x=[x 0 ,x e ]=[0,1]. The input angle variation range △θ is 100°, the value range of the objective function △ψ is 45°, and the mechanism design tolerance ε is 0.35mm. The manufacturing tolerance of the rods of the mechanism is 0.15mm. Therefore, define the size interval variable △l i (i=1,2,3,4) has a radius of 0.15 mm. The clearance circle radius for all 4 hinges is 0.02mm. The design range of the transmission angle of the mechanism is [20°, 160°]. The input angle is discretized into 100 interval segments. of all constraints is 0.999.

[0134] pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com