Automatic-distribution feeding device

An automatic feeding trough technology, applied in the field of breeding, can solve the problems of uneven material distribution and food rush

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

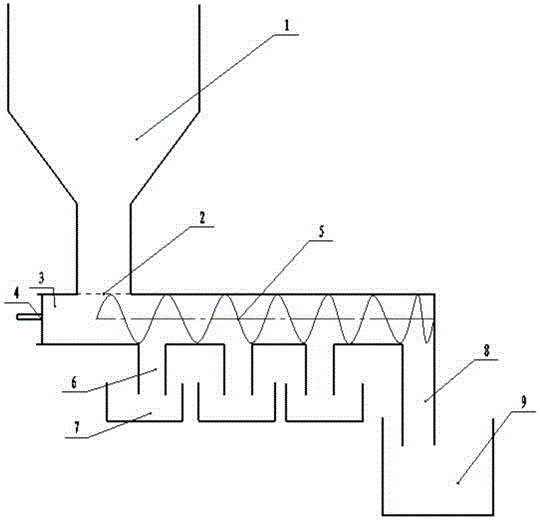

[0010] The present invention will be further explained in combination with specific embodiments and schematic structural diagrams of the present invention. There are 3 feeding ports and feeding troughs respectively in this specific embodiment. This is like figure 1 As shown, the pig food mixed in advance is added to the storage box 1, and the pig food enters the distribution box 3 along the automatic partition 2. When the pig food is full of the front end of the distribution box 3, the motor is started, and the pushing plate 4 Push the pig food in the distribution box 3 into the push screw 5, and with the rotation of the push screw 5, the pig food enters the middle part of the distribution box, and when it reaches the first feeding port 6, the pig food goes along the first The feeding port enters the first feeding trough 7. When the pig food in the feeding trough 7 is full, the pig food will enter the second feeding trough 7 along the second feeding port 6. After the second f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com