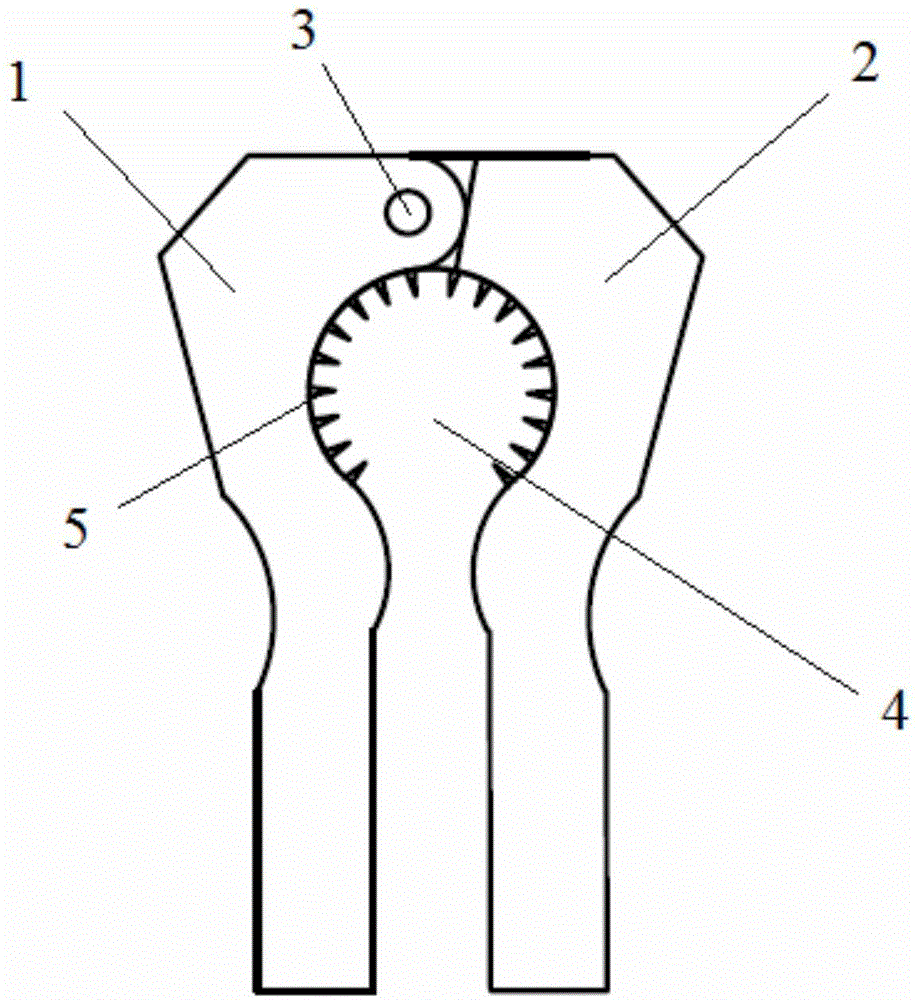

Handheld walnut cracker

A technology for breaking shells and walnuts, which is used in household appliances, applications, kitchen utensils, etc., can solve the problems of unbreakable walnut shells, and achieve the effects of low cost, increased torque, and improved structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] A hand-held walnut shell cracker, including a first clamping part, a second clamping part, a connecting part, a circular hollow, and acupuncture, wherein the first clamping part and the second clamping part are connected by a shaft through the connecting part, and the second clamping part is A circular hollow is formed between the first clamping part and the second clamping part, and 10 iron needles are evenly distributed on the edge of the circular hollow.

Embodiment 2

[0015] A hand-held walnut shell cracker, including a first clamping part, a second clamping part, a connecting part, a circular hollow, and acupuncture, wherein the first clamping part and the second clamping part are connected by a shaft through the connecting part, and the second clamping part is A circular hollow is formed between the first clamping part and the second clamping part, and 20 stainless steel needles are evenly distributed on the edge of the circular hollow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com