An automatic pressing device for pressing wires into terminals

A press-in device and moving device technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of small shape, unstable product quality, and low output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

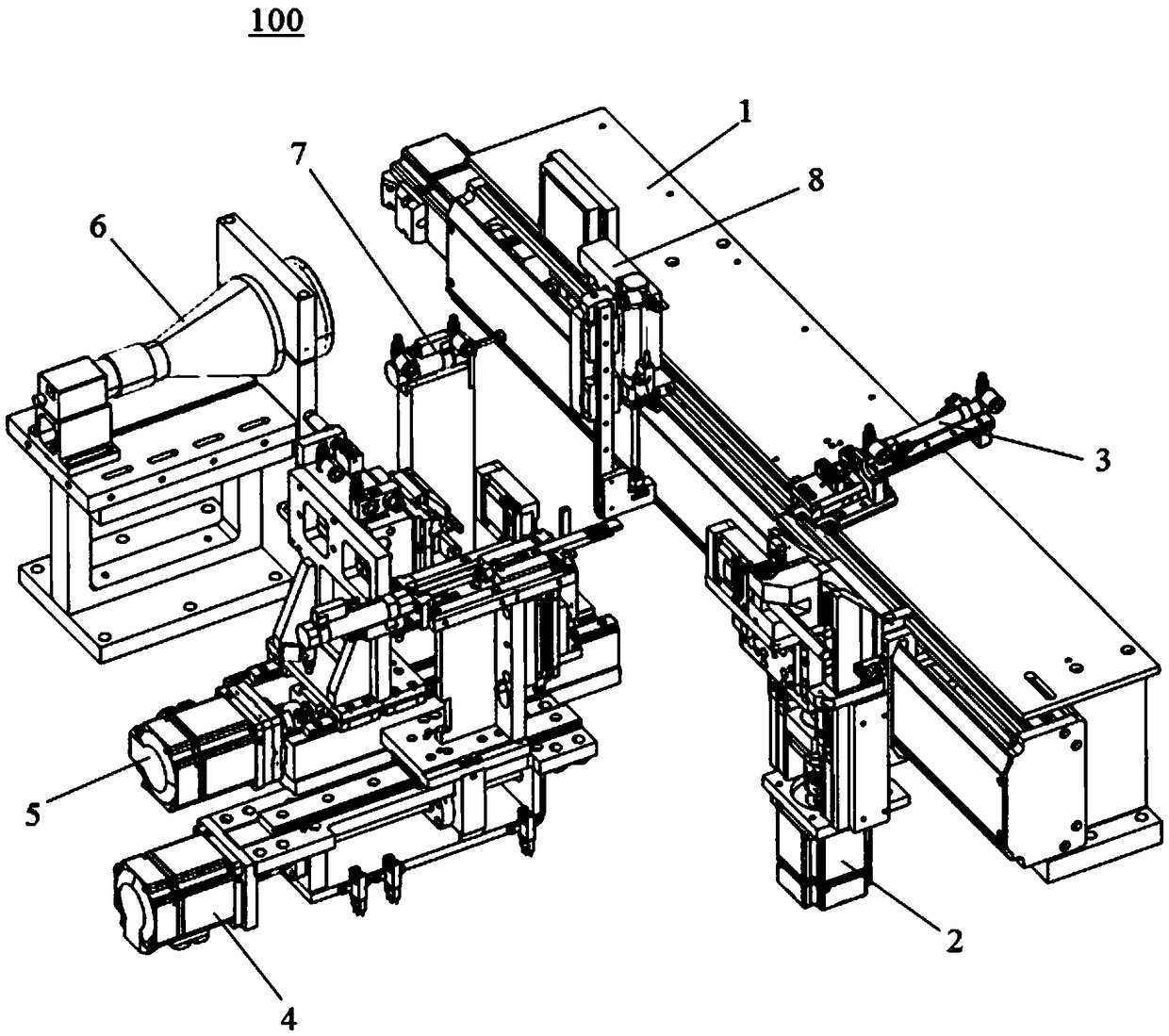

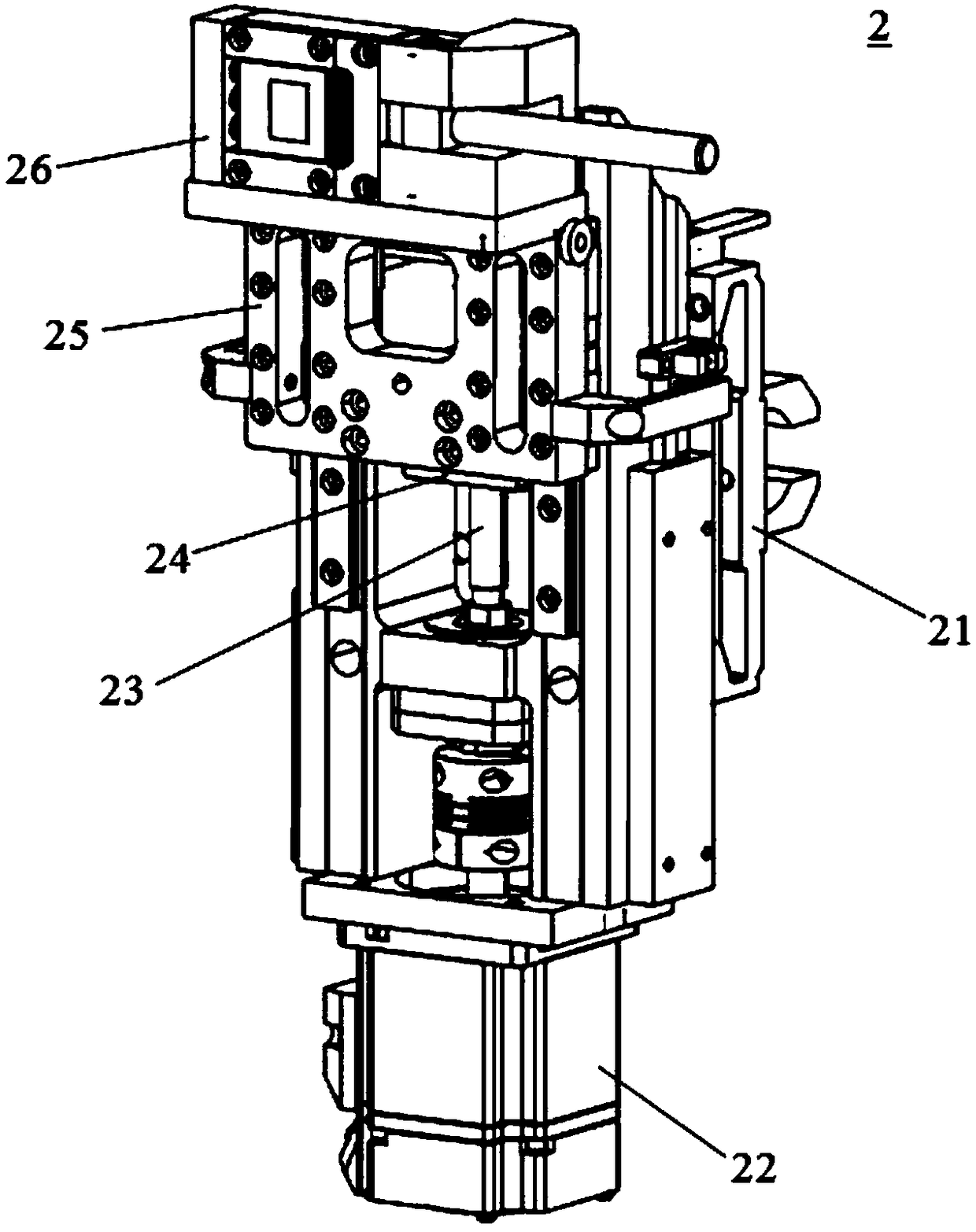

[0041] Please refer to Figure 1-Figure 9 , the present embodiment is an automatic press-in device 100 for pressing wires into terminals, which includes a terminal moving device 1, a terminal positioning device 2 moving on the terminal moving device 1, a thimble device 3 fixed on the terminal moving device 1, and The terminal moving device 1 is vertically arranged and the wire pressing device 4 corresponding to the position of the thimble device 3, the wire input device 5 arranged beside the wire pressing device 4, the CCD camera device 6 arranged beside the wire input device 5, and the wire input device 6 arranged beside the wire input device The terminal flattening device 7 between the input device 5 and the CCD camera device 6 , and the shaping device 8 used in conjunction with the terminal pressing device 4 .

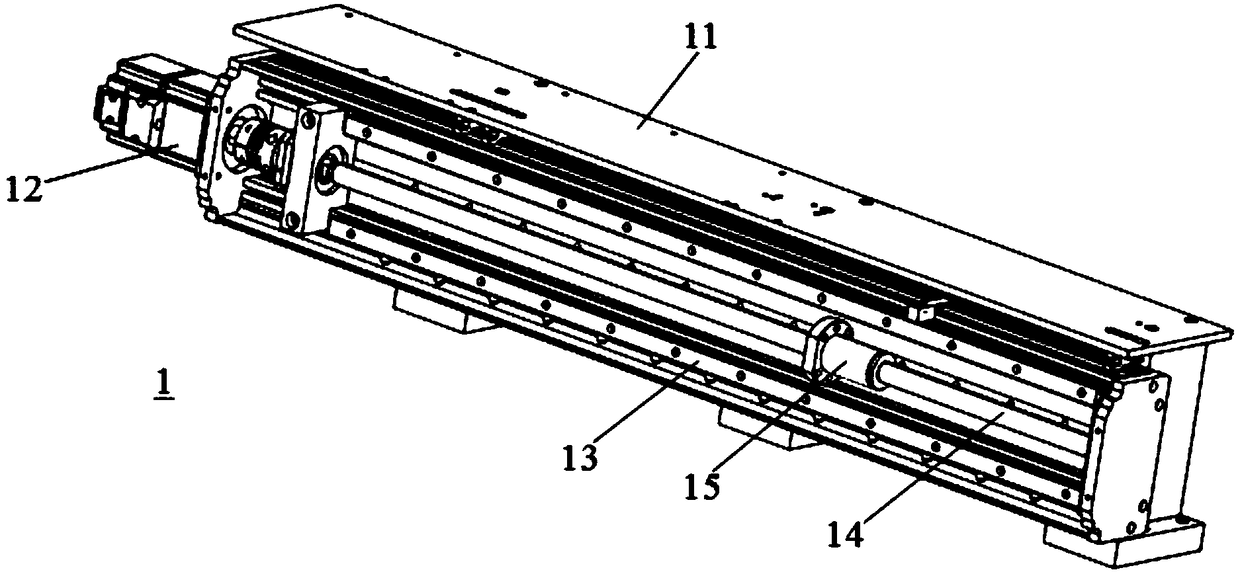

[0042] The terminal moving device 1 includes a first support 11, a first driving device 12 fixed on the first support 11 and providing left and right driving force,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com