Full-automatic hydrogen receiving and filling system of hydrogen refueling station

A technology of filling system and hydrogen filling station, applied in the field of fully automatic hydrogen receiving and filling system of hydrogen filling station, can solve the problems of wasting manpower and a lot of time and energy, irregular quality data recording, safety risk of hydrogen leakage, etc. To achieve the effect of reducing cumbersome and reducing personnel costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described in detail with reference to the accompanying drawings.

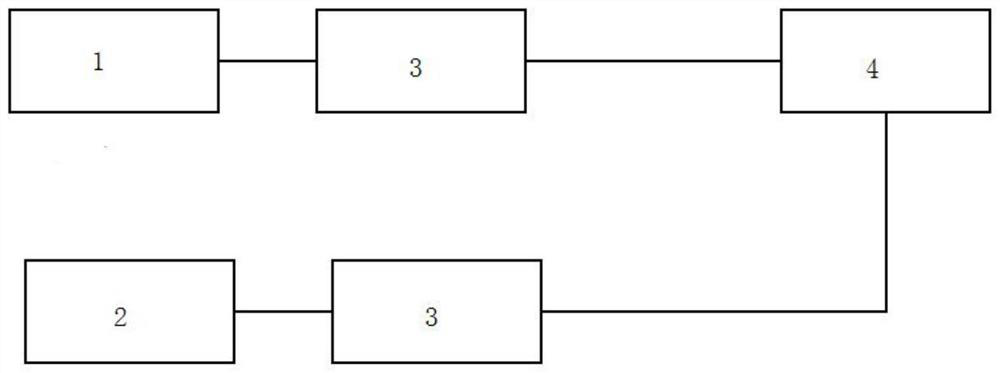

[0023] An embodiment of the present invention provides a fully automatic hydrogen receiving and filling system for a hydrogen refueling station. Please refer to figure 1 , figure 1 It is a working principle diagram of a fully automatic hydrogen receiving and filling system of a hydrogen refueling station in the embodiment of the present invention, including: automatic vehicle identification subsystem, voice prompt and ground lighting subsystem, hydrogen robot automatic receiving subsystem and filling device ;

[0024] Automatic vehicle identification subsystem, including on-site automatic camera function camera, access control device and vehicle information control system, the vehicle information includes vehicle license plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com