Robot-assisted automatic assembly and lubricating oil addition equipment for rolling wheel assemblies

A robot-assisted and automatic assembly technology, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as failure to meet transportation requirements and insecurity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

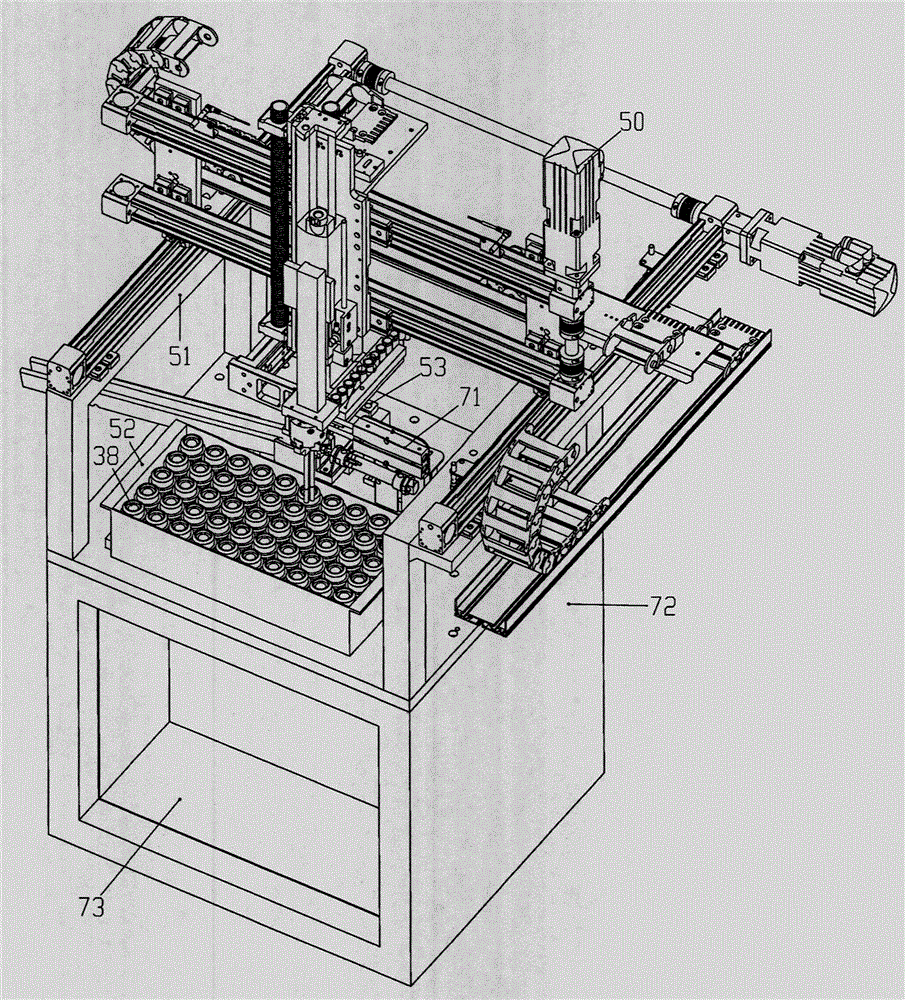

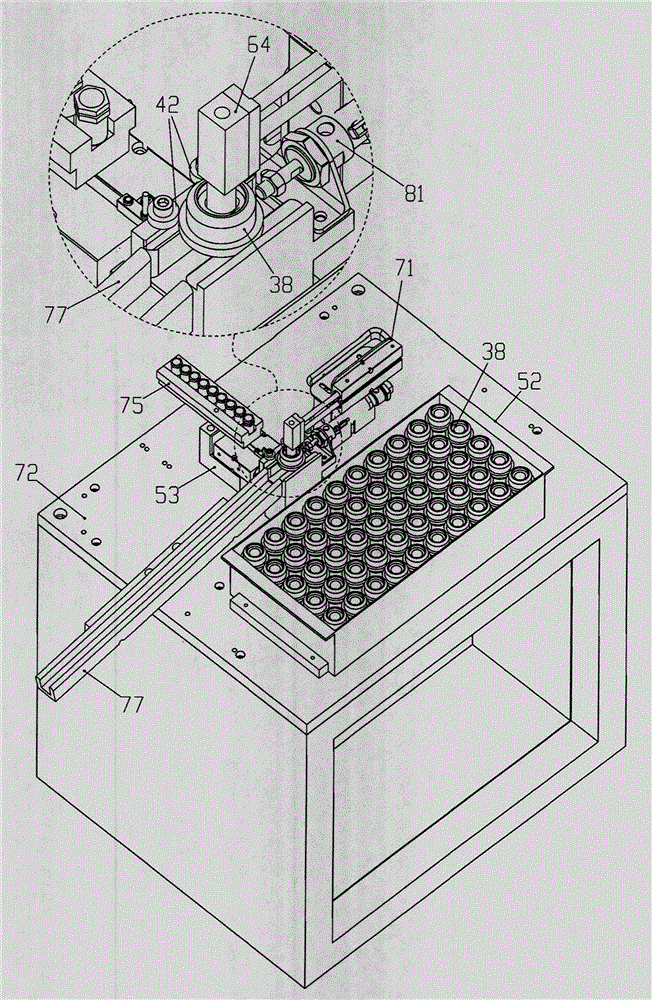

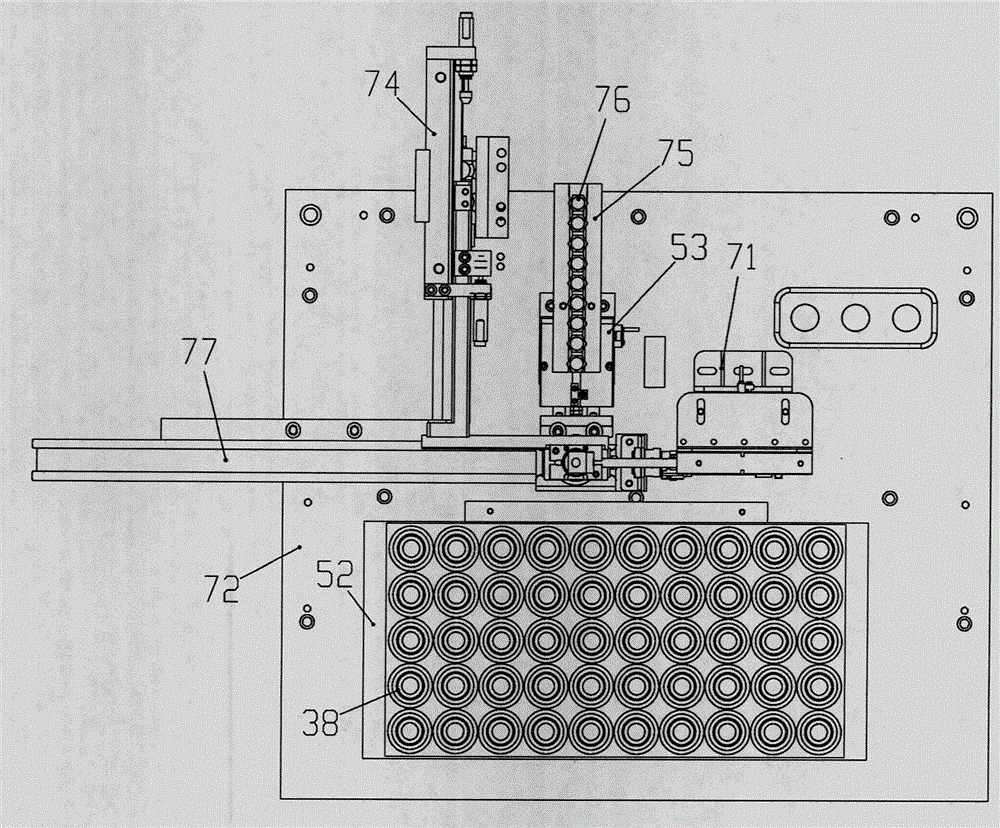

[0069] The present invention will be further described in detail below in conjunction with the accompanying drawings, but does not constitute any limitation to the present invention. Similar component numbers in the accompanying drawings represent similar components. As mentioned above, the present invention provides a robot-assisted automatic assembly of roller assemblies and lubricating oil addition equipment. The present invention is used in the automatic assembly of roller assemblies in the process of mechanical manufacturing, and adds a precise amount of lubricant to the inner holes of the rollers. Oil; the robot-assisted automatic assembly of the roller assembly and lubricating oil addition equipment of the present invention realizes the unmanned operation of the roller assembly, has high work efficiency, good product quality, and precisely controls the dosage of the added lubricating oil, achieving the goal of machine substitution Purpose.

[0070] figure 1 It is a sch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com