Automatic laminaria japonica flatting shredding machine

A shredding machine and kelp technology, applied in metal processing and other directions, can solve the problems of low shredding efficiency, low operation safety, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

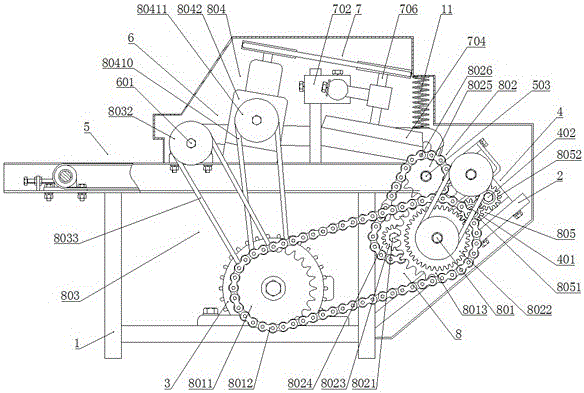

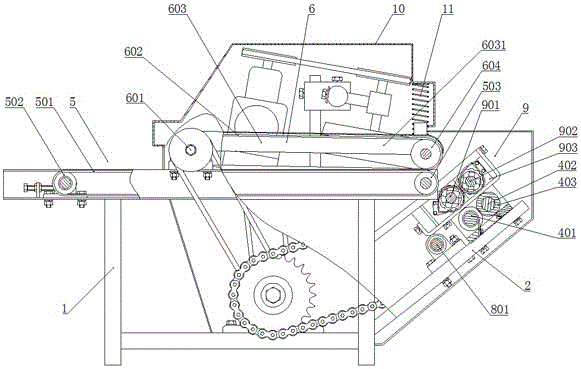

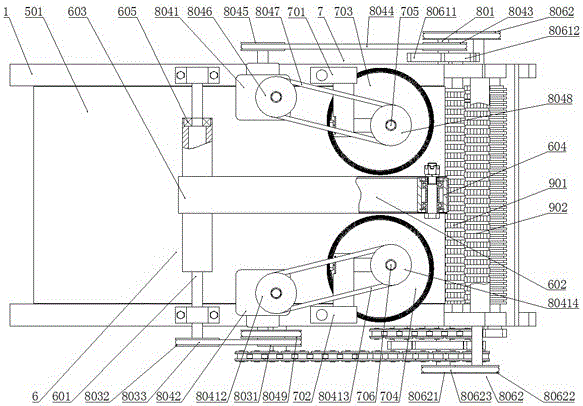

[0026] exist figure 1 Among them, an automatic flattening kelp shredding machine includes a frame 1, a driving motor 3 and a shredding device 4. Wherein, the drive motor 3 is installed on the frame 1, and an outstretched support 2 is installed outside the discharge end of the frame 1.

[0027] The shredded device 4 is used to cut the sea-tangle into silk by strip-like cutting. Such as figure 2As shown, it includes a driving knife shaft 401, a driven knife shaft 402 and several circular blades 403, wherein the driving knife shaft 401 and the driven knife shaft 402 are arranged in parallel, and they are respectively rotatably supported by corresponding knife seats and bearings. On the bracket 2 , the circular blades 403 are mounted on the driving cutter shaft 401 and the driven cutter shaft 402 respectively at intervals and non-rotatingly, and the adjacent circular blades 403 on the two cutter shafts are interlaced. It should be noted that the number and thickness of the cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com