Serpentine belt braiding machine

A braiding machine and serpentine belt technology, applied in the field of braiding machines, can solve the problems of unstable diameter deviation, low yield, uneven pitch of serpentine belts, etc. Even pitch effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

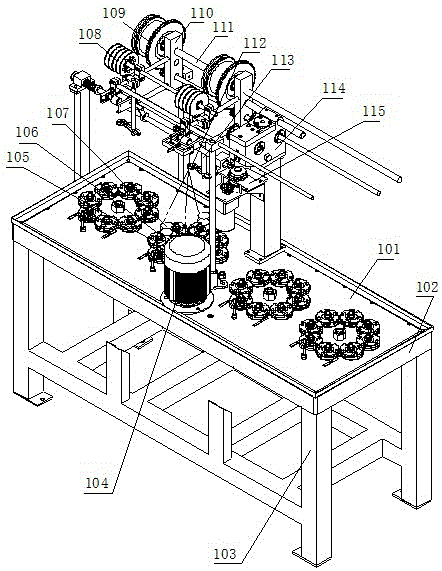

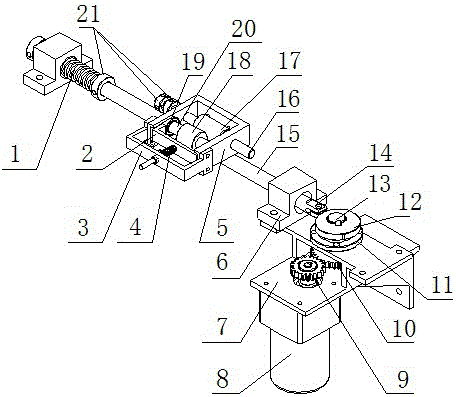

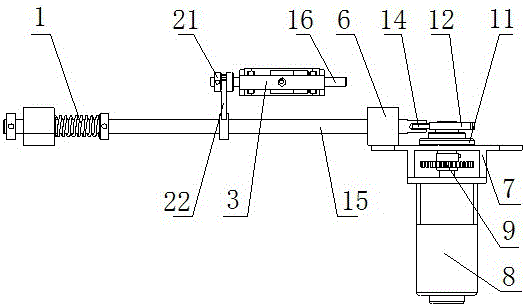

[0018] Embodiment 1: the braiding machine includes: upper plate 101, lower plate 102, frame 103, host motor 104, spindle driving device, wire take-up device, serpentine transmission device 115 and support column 116; sequentially connected on frame 103 There is a lower plate 102 and an upper plate 101, on which a spindle driving device, a main machine motor 104 and a support column are connected, and a wire take-up device and a serpentine transmission device are connected on the support column, and the wire take-up device is located at the side of the serpentine transmission device. above.

[0019] The spindle driving device includes: a dial 105, a dial shaft 106 and a spindle 107; the dial 105 is sleeved on the dial shaft, and a spindle is connected between the upper edges of the dial, and the spindle is stuck on the outer edge of the dial for control and can slide along the direction of the guide rail on the upper and lower sides of the outer edge of the dial.

[0020] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com