Serpentine belt transmission device for braiding machine

A transmission device and serpentine belt technology, which is applied to transmission devices, braids, mechanical equipment, etc., can solve problems such as unstable diameter deviation, low yield, and uneven pitch of serpentine belts, so as to save raw materials and improve Product quality and output, the effect of uniform serpentine pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

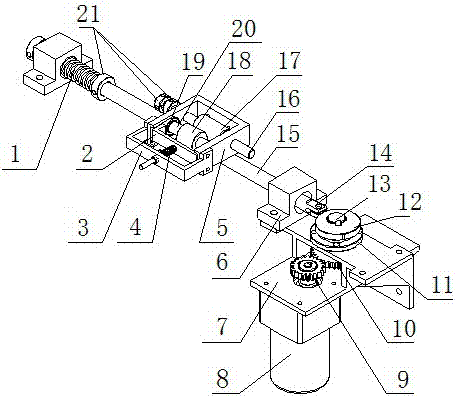

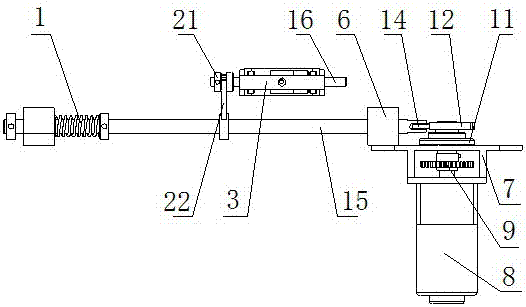

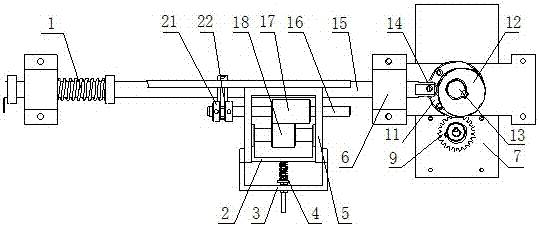

[0014] Embodiment 1: The transmission device includes: a roller moving mechanism and a driving mechanism; the roller moving mechanism and the driving mechanism are rollingly connected through their cams and rollers.

[0015] The roller moving mechanism includes: telescopic spring 1, roller bracket 5, shaft seat 6, roller shaft 14, travel shaft 15, travel roller shaft 16, travel wheel 17, roller 18, bearing 19, roller shaft 20, retaining ring 21 and a tension compression device; the roller bracket 5 is a frame surrounded by three sides, one side is an opening, and the walking roller shaft 16 passing through is arranged on the two side walls of the frame, and there is a concave hole in the inner side of the frame side wall passing through the shaft. The two ends of the roller shaft 20 are connected with bearings 19; the outer circle of the bearing 19 is positioned in the grooves on both sides of the roller bracket 5, and the outer circle of the bearing 19 can slide in the groove,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com