Clamp detecting device

A detection device and fixture technology, applied in the direction of color/spectral characteristic measurement, etc., can solve the problems of easy missed detection, labor cost, low efficiency, etc., and achieve the effect of high accuracy and labor cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

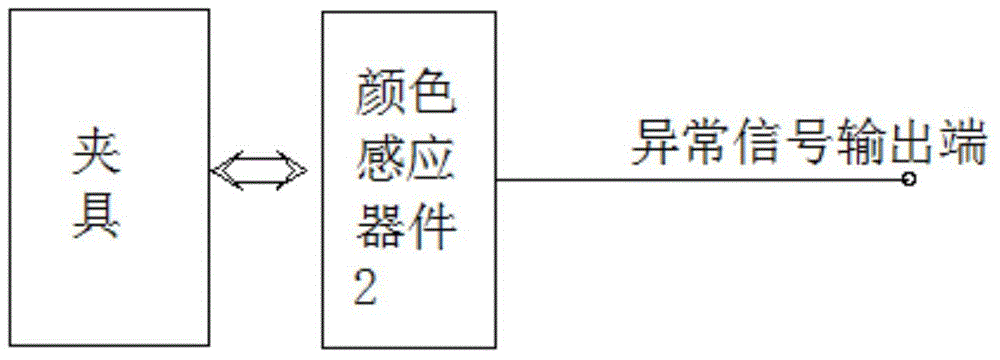

[0027] like figure 1 As shown, this embodiment provides a fixture detection device, including at least one color sensing device 2, which is arranged on one side of the fixture, and a standard color value and a color difference threshold are preset in the color sensing device 2, which acquires the current color of the fixture value and compare it with the preset standard color value, when the difference between the obtained current color value and the standard color value exceeds the color difference threshold, an abnormal signal is output. This fixture detection device is mainly used to detect whether the fixture of the vertical continuous electroplating line is copper-bonded. The surface of the normal fixture is silver-white, which is set as the standard color value. When the fixture is copper-bonded, the surface color of the copper-bonded position will become Red copper color, when the color sensing device 2 detects red copper color, that is, when the difference between the ...

Embodiment 2

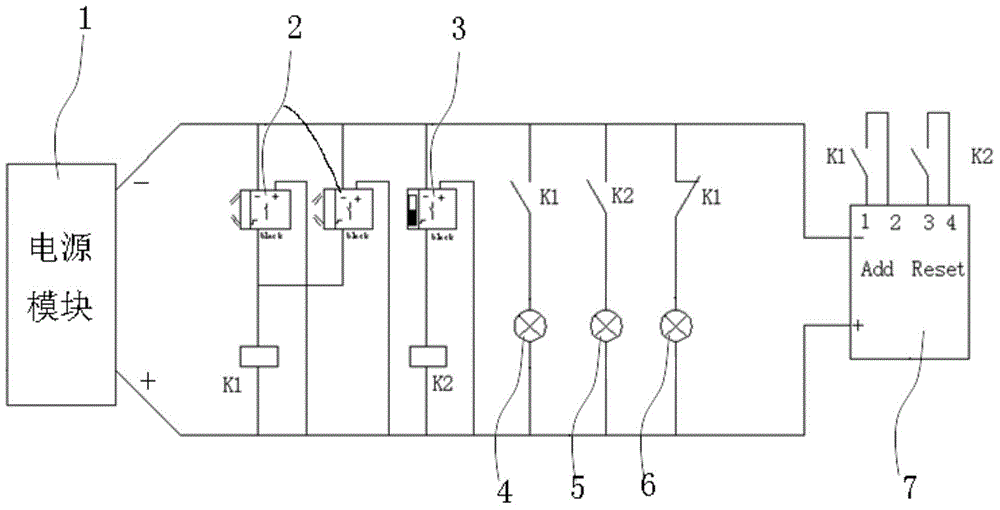

[0029] like figure 2 As shown, this embodiment provides a fixture detection device, including two color sensing devices 2, which are respectively arranged on both sides of the fixture, to obtain the current color value on both sides of the fixture, and compare it with the preset standard color value, If the difference between the current color value and the standard color value exceeds the threshold, an abnormal signal is output. This fixture detection device is mainly used to detect whether the fixture of the vertical continuous electroplating line is copper-bonded. The normal surface of the fixture is silvery white. When the fixture is copper-bonded, the surface color of the copper-bonded position becomes red copper. When it is red copper, it is judged that the corresponding fixture is copper-bonded. The purpose of setting two color sensing devices 2 to detect both sides of the fixture at the same time is to make the detection of the copper junction of the fixture more acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com