Base and plasma processing equipment

A pedestal and metal disc technology, which is applied in the manufacture of semiconductor/solid-state devices, discharge tubes, electrical components, etc., can solve the problems of reducing the service life of the metal disc 10, contaminating the substrate, increasing maintenance costs, etc., and achieving improved uniformity. performance, cost reduction, and the effect of changing RF coupling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to enable those skilled in the art to better understand the technical solution of the present invention, the susceptor and plasma processing equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

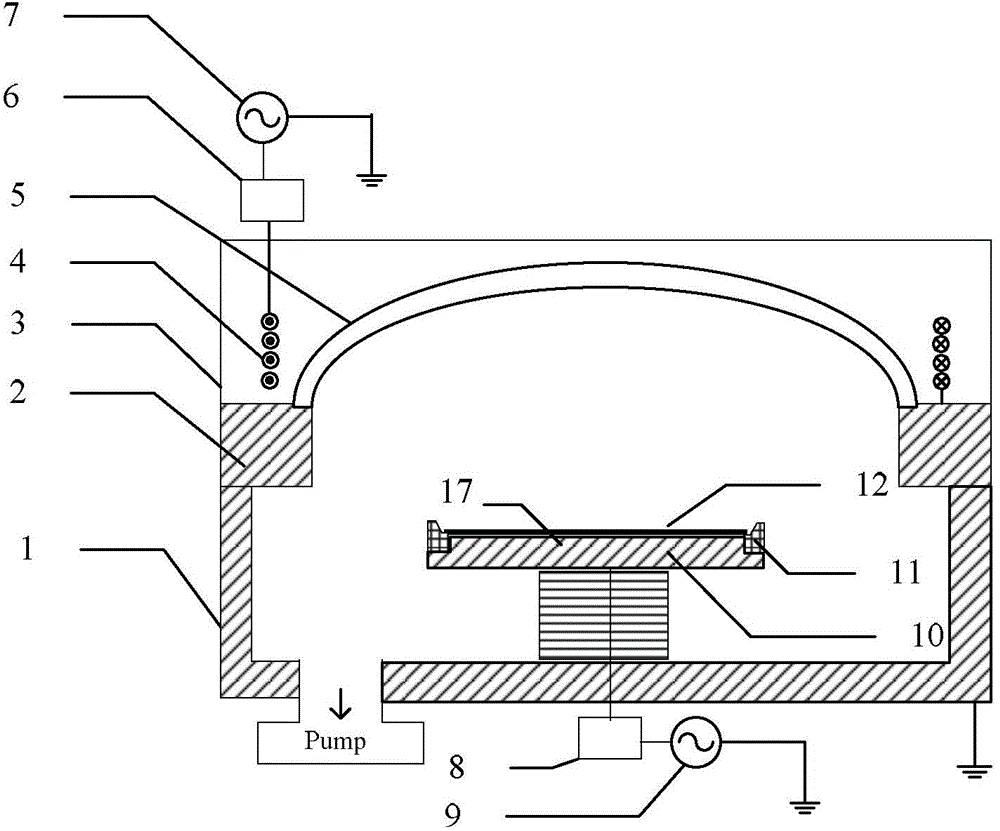

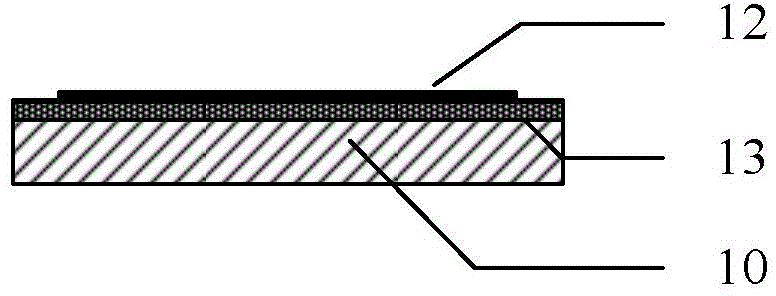

[0024] Plasma processing equipment can be used to perform processes such as thin film deposition and etching. figure 1 A schematic diagram of the plasma processing equipment used for etching. Such as figure 1 As shown, the plasma processing equipment includes a reaction chamber, the reaction chamber includes a reaction chamber 1, a metal ring part 2 and a dome-shaped insulating top cover 5, the dome-shaped insulating top cover 5 is arranged on the top of the reaction chamber 1, and the metal The annular component 2 is arranged between the reaction chamber 1 and the dome-shaped insulating top cover 5 . A cylindrical three-dimensional coil 4 is arranged around the outside of the dome-shaped insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com