Stress-induced light-emission material, method for manufacturing stress-induced light-emission material, stress-induced light-emission paint composition, resin composition, and stress-induced light-emission body

A resin composition, stress luminescence technology, applied in luminescent materials, luminescent coatings, chemical instruments and methods, etc., can solve the problems of reduced luminous intensity, insufficient reduction of luminous intensity, lack of water resistance, etc., and achieve full water resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0186] 0.45 g of diammonium hydrogen phosphate (manufactured by Wako Pure Chemical Industries, Ltd.) was weighed in a container, and 30 mL of pure water was added and stirred to obtain a slurry containing a phosphoric acid compound.

[0187] Put 15 g of the above-mentioned europium-activated strontium aluminate (1) particles [SAO particles (1)] into a 100 mL plastic container, add the above-mentioned slurry to prepare a mixed solution, and then add 80 g of alumina balls with a diameter of 1.5 mm to obtain a slurry.

[0188] The slurry was pulverized for 25 minutes using a planetary ball mill (manufactured by Fritsch Japan Co., Ltd.) at a rotational speed of 150 rpm, and the slurry was passed through a stainless steel strainer to remove alumina balls to obtain a pulverized slurry. The relative centrifugal acceleration at this time G(m / s 2 ) is 3.08.

[0189] The product of the relative centrifugal acceleration G and the time (hour) of the crushing process was 1.28.

[0190] T...

Embodiment 2

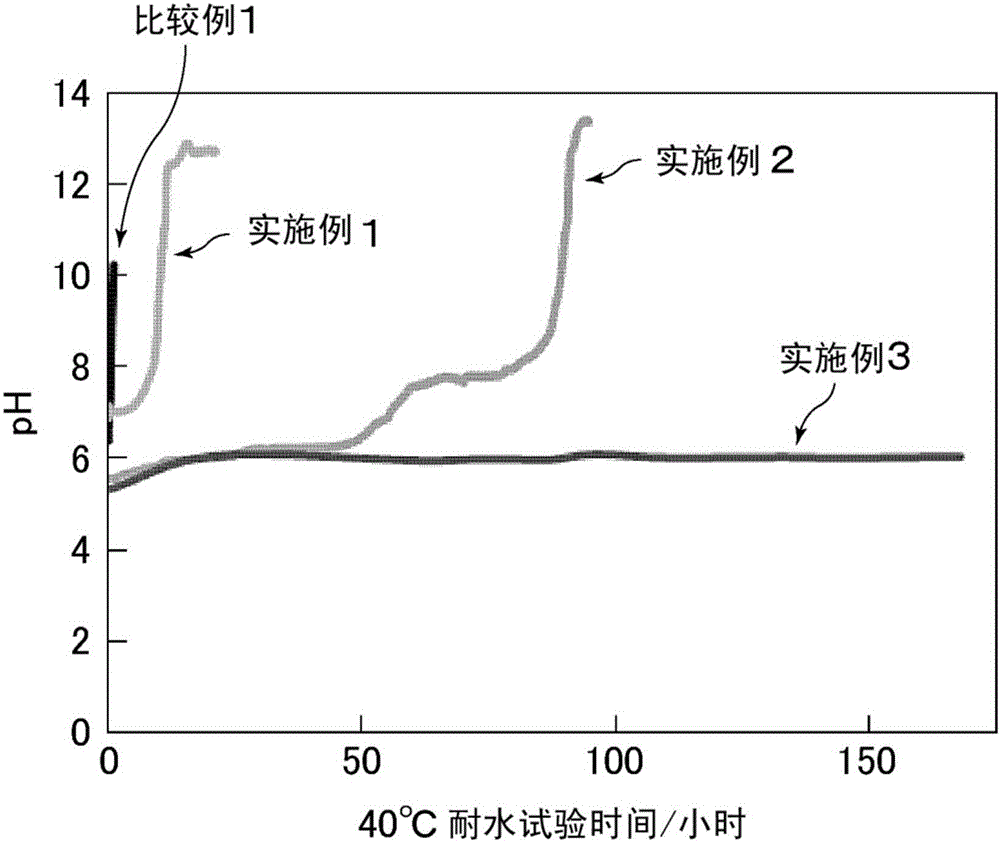

[0193] In Example 1, the pulverized slurry from which alumina balls were removed was stirred for 4 hours, and then a drying process was performed using an atomizer-type spray dryer (direct heating spray drying device) to make SAO particles (1 ) reacts with a phosphoric acid compound to obtain a stress luminescent material with a surface treatment layer formed.

[0194] The content A of the strontium element in the stress light-emitting material was measured by the same method as in Example 1, and it was 32.1% by weight.

Embodiment 3

[0196] In Example 2, after the drying step, a heat treatment step of heating with an electric dryer at 200°C for 2 hours was performed to react the surface of the SAO particles (1) with a phosphoric acid compound, thereby obtaining stress luminescence with a surface treatment layer formed. Material.

[0197] The content A of the strontium element in the stress light-emitting material was measured by the same method as in Example 1, and it was 31.8% by weight.

[0198] In addition, the content of phosphorus element in the stress light-emitting material was measured by the same method as the content of strontium element, and it was 0.72% by weight.

[0199] In the stress luminescent material, the content of phosphorus element relative to 100 parts by weight of europium-activated strontium aluminate particles is 0.70 parts by weight.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com