Aqueous dispersion composition and use of same

A water-based dispersion and composition technology, applied in the direction of medical preparations containing active ingredients, dressing preparations, cosmetics, etc., can solve the problems without any records and revelations, and achieve excellent operability and sufficient hydrophobicity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0163] Hereinafter, the present invention will be described in more detail based on examples, but the present invention is not limited to these examples at all. Unless otherwise specified, the compounding quantity of each component shows "mass %" ("weight %"). In addition, below, the aqueous dispersion composition of an Example etc. is abbreviated as "aqueous dispersion".

[0164] Carboxylic acid-modified silicone (compound 1 and compound 2) which is the component (A) of this invention was synthesize|combined by the following method.

Synthetic example 1

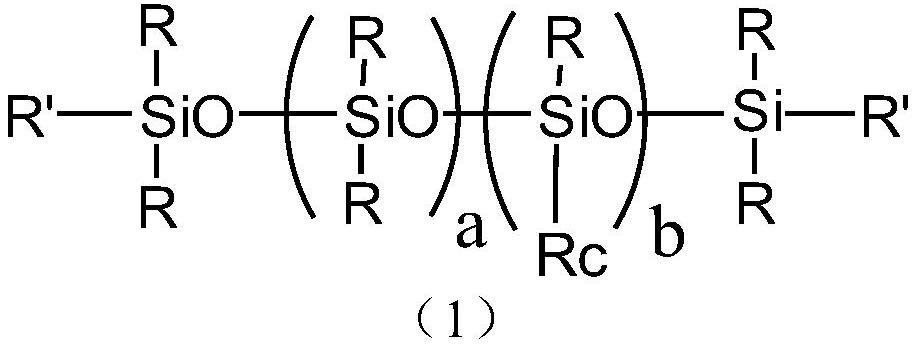

[0166] Add 230.67 g of trimethylsilyl undecylenate and platinum-1,3-divinyl-1,1,3,3-tetramethyl to a flask equipped with a stirrer, a reflux condenser, a dropping funnel, and a thermometer. 0.042 g of the base disiloxane complex, and 129.33 g of Si-H siloxane represented by the following structural formula were added dropwise so as to maintain the range of 70-80°C.

[0167] [chemical formula 10]

[0168]

[0169] After completion of the dropwise addition, aging was performed at 110° C. for 2 hours, and the disappearance of the Si—H bond was confirmed by a hydrogen generation method. Low boiling point components were distilled off under reduced pressure. Thereafter, 90 g of deionized water was added, and aging was performed for 4 hours under reflux to perform deprotection. Thereafter, the low boiling point components were removed again under reduced pressure to obtain Compound 1. As a result of the analysis, it was confirmed that it was Compound 1 represented by the follo...

Synthetic example 2

[0174] Add 100 g of 1,1,1,3,5,5,5-pentamethyltrisiloxane, platinum-1,3-divinyl- 0.02 g of toluene solution of 1,1,3,3-tetramethyldisiloxane complex was added dropwise to 105 g of undecylenic acid trimethylsilyl ester so as to maintain the range of 70-100°C. After completion of the dropwise addition, aging was performed at 110° C. for 2 hours, and the disappearance of the Si—H bond was confirmed by a hydrogen generation method. Low boiling point components were distilled off under reduced pressure. Thereafter, water was added, and aging was carried out for 4 hours under reflux to perform deprotection. Thereafter, the low boiling point components were again removed under reduced pressure to obtain compound 2. As a result of the analysis, it was confirmed that the chemical structure of Compound 2 is represented by the following chemical formula.

[0175] Compound 2:

[0176] [chemical formula 12]

[0177]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com