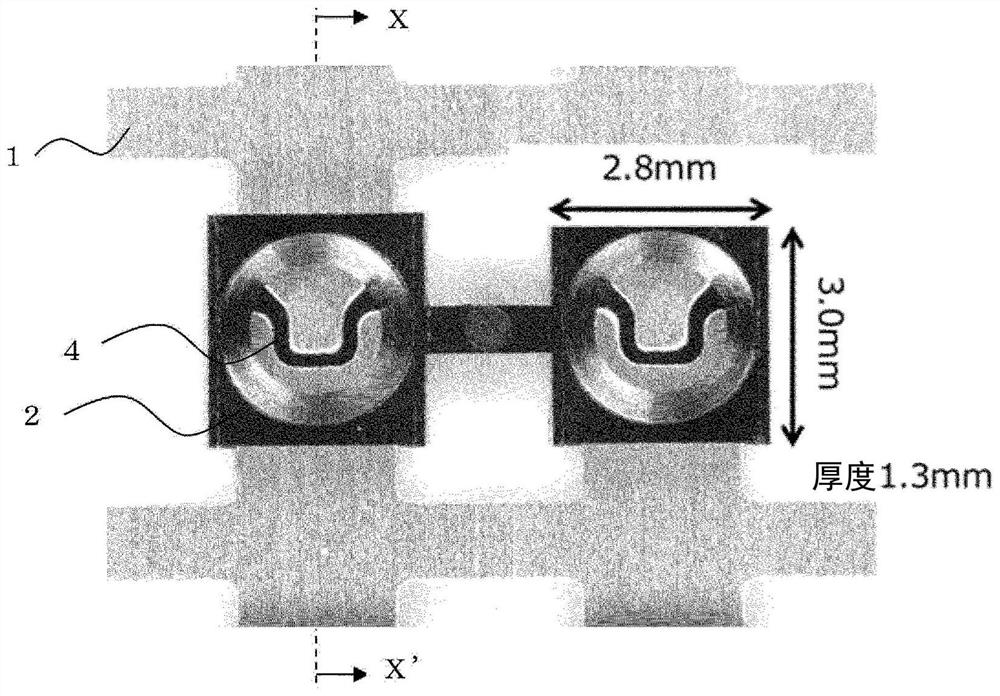

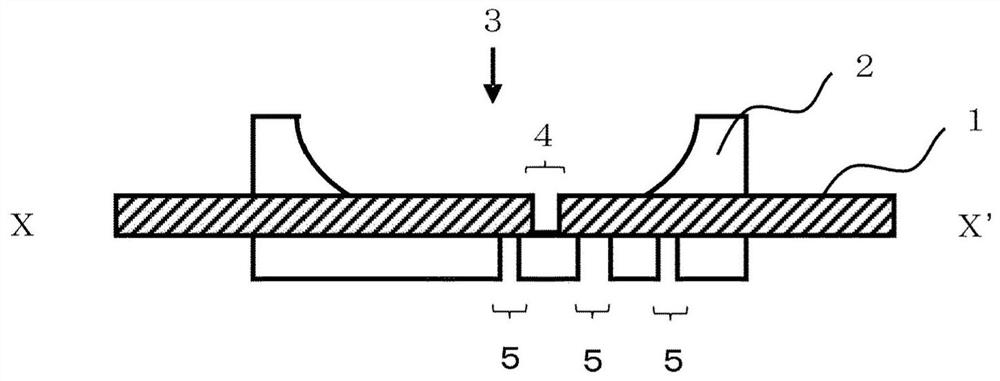

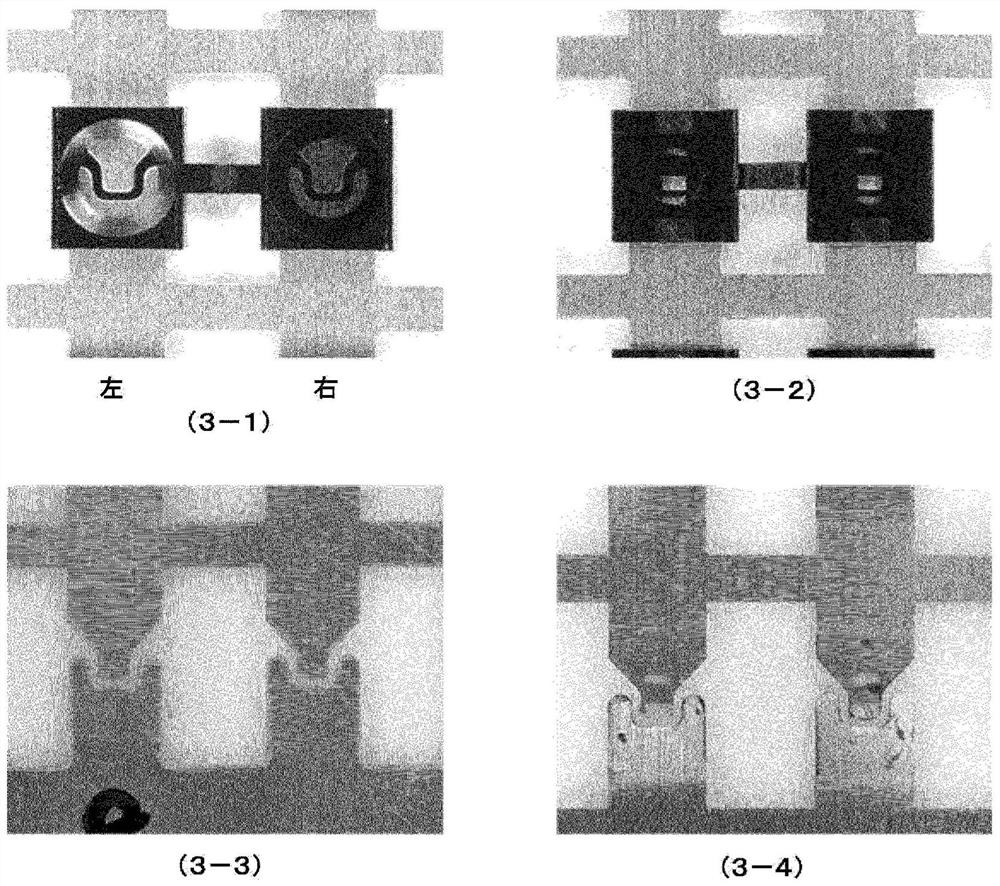

Waterproof component, electronic equipment comprising same, waterproofing method using insert-molded body, and waterproofing method for electronic equipment

A technology for electronic equipment and moldings, applied in the field of waterproof parts, which can solve the problems of finished parts, elastic body production costs, and difficulties in miniaturization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6 and comparative example 1~3

[0145] Through the most upstream hopper, the thermoplastic resin (A) shown in Table 1 and other components were supplied to a twin-screw extruder (screw diameter: 32 mm, L / D = 30, rotation speed: 150 rpm, In a discharge rate of 10 kg / h), the inorganic filler (B) shown in Table 1 was further supplied from a side feeder, and melt-kneaded. The melt-kneaded thermoplastic resin composition was extruded into a strand, cooled and then cut to obtain pellets of the thermoplastic resin composition. It should be noted that the amounts of the thermoplastic resin (A), the inorganic filler (B) and other components in Table 1 all mean "parts by mass".

[0146] Using these pellets, evaluation as a molded product (insert molded product) was performed by the following method.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com