Efficient concentrator with self-cleaning and rake pressing prevention functions

A concentrator and self-cleaning technology, which is applied to the feeding/discharging device of the settling tank, settling tank, chemical instruments and methods, etc., can solve the lack of research on the overflow weir of the concentrator, the turbulence of the agent and the body of the slime water concentrator The problem of small flow rate can be achieved to shorten the transportation distance, ensure the effective working volume, and avoid the effect of agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

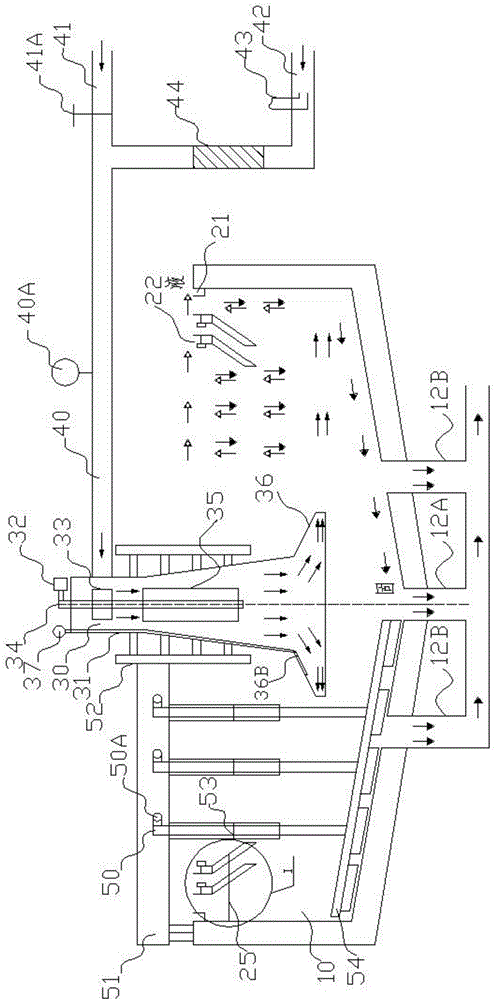

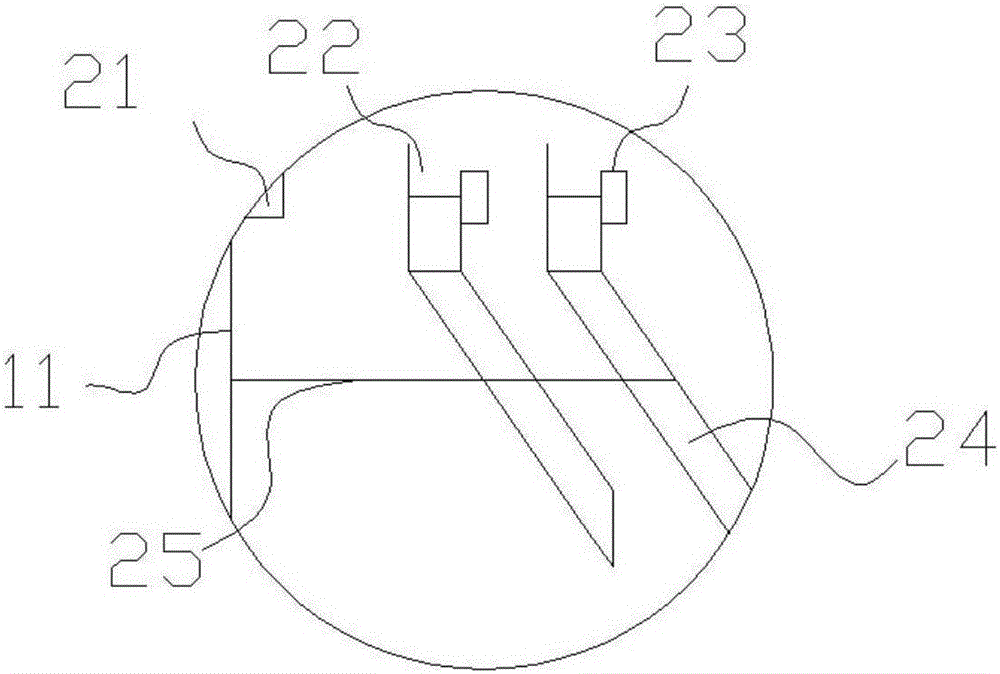

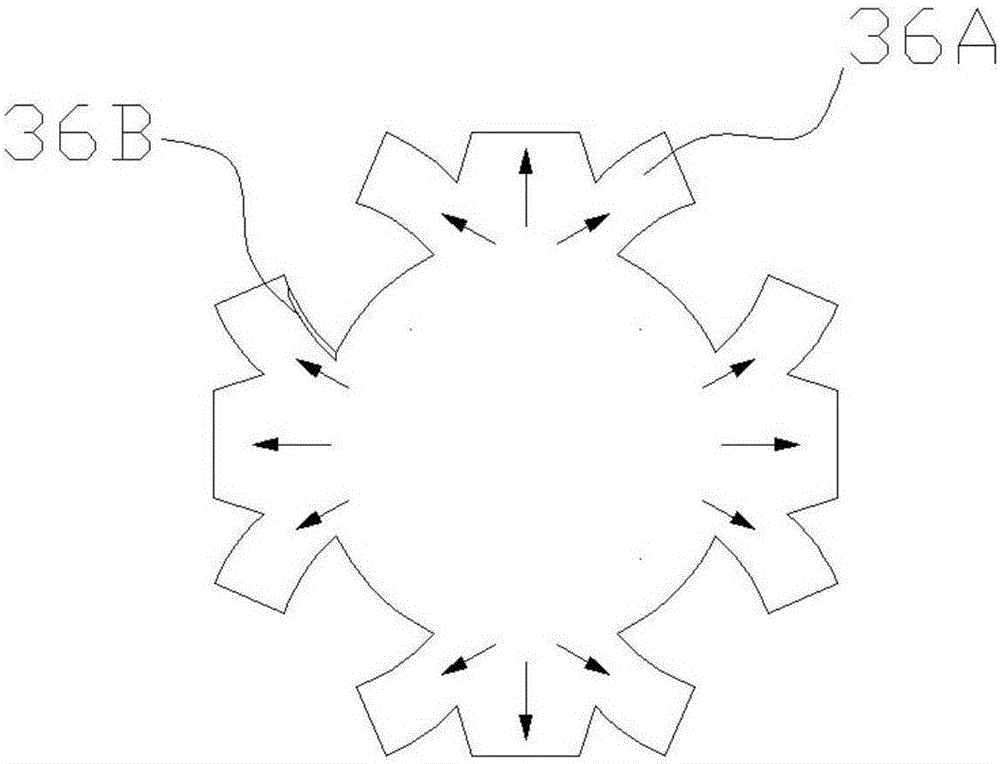

[0031] For ease of understanding, combined here Figure 1-4 , the specific embodiments of the present invention are further described as follows:

[0032] The specific components of the present invention are divided into several major modules, including: thickener body 10 , feeding pipeline driving stirring mechanism 30 , overflow weir 20 and hydraulic rake lifting device 50 . Describe them one by one below:

[0033] 1. Concentrator body

[0034]The body of the thickener is the basic structure of the thickener, which provides enough volume for the flocculation, sedimentation and clarification of the slime water. The bottom outlet (12) is used for the discharge of high-concentration sediment, including the center bottom outlet (12A) and the side bottom outlet. (12B), the center bottom outlet (12A) is located at the center of the ring at the bottom of the concentrator, and the side bottom outlet (12B) is arranged in the vertical and horizontal directions of the center bottom o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com