Gauge structure of single cone bit

A single cone and drill bit technology, which is applied in the direction of drill bits, drilling equipment, earthwork drilling, etc., can solve the problems of poor safety performance, inability to make the well wall smooth and smooth, and low practical value, and achieve the effect of reducing flow resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

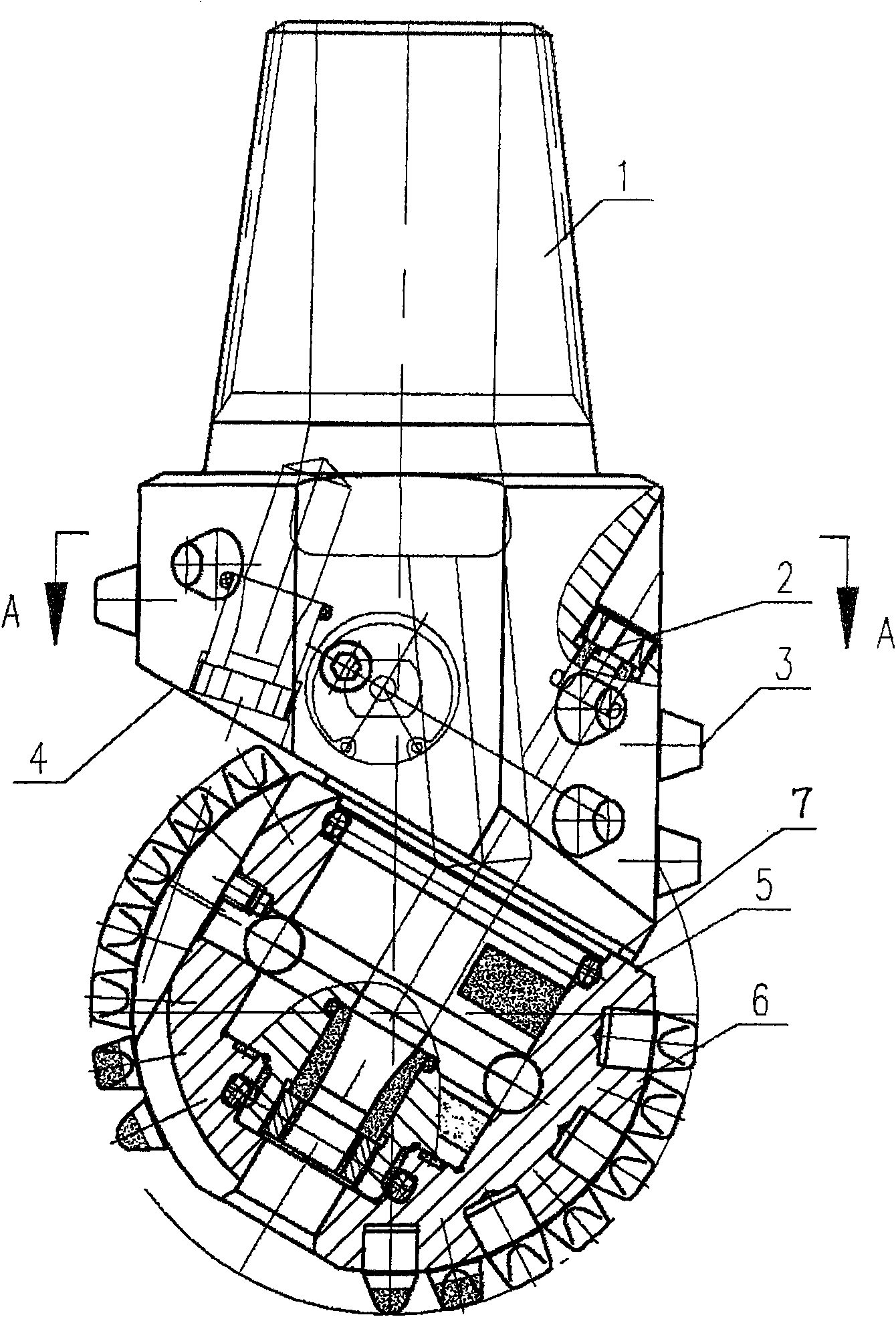

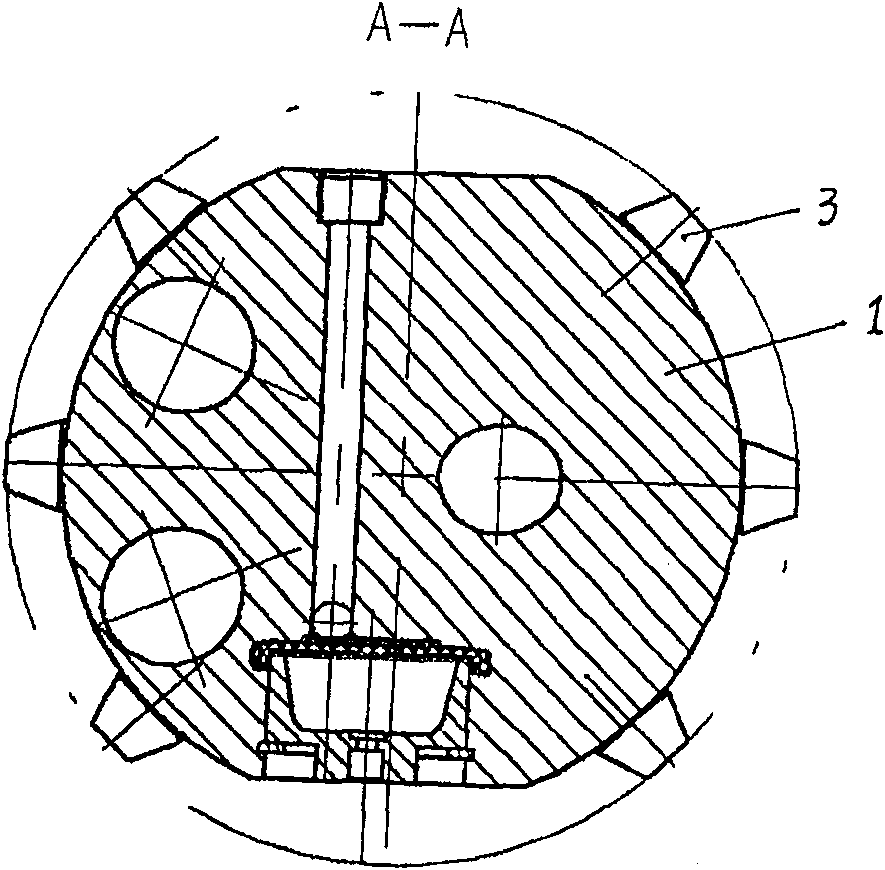

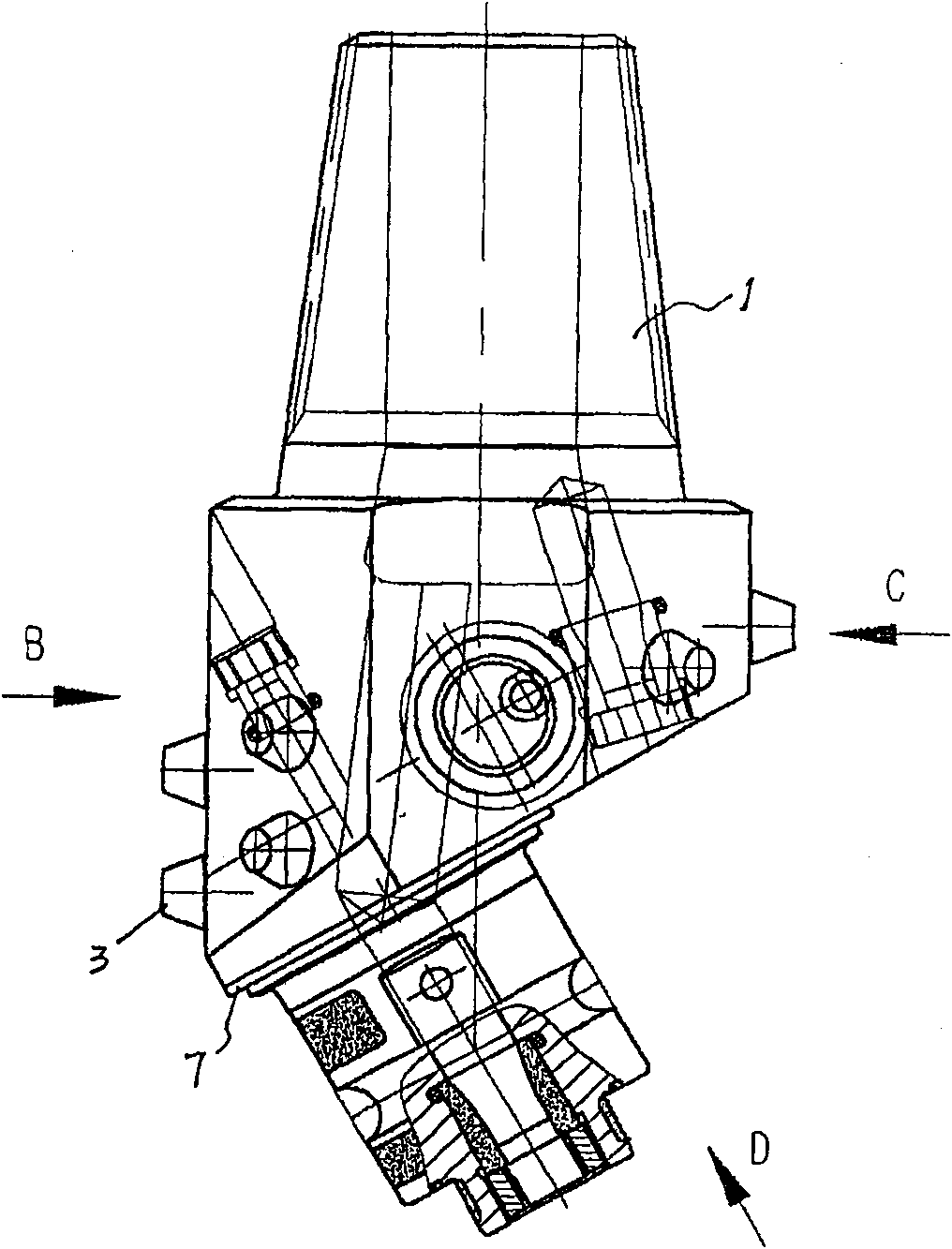

[0019] Such as Figure 1-6 The schematic diagram of the diameter-gauge structure of the single-cone drill bit of the present invention is shown in each direction. The cylindrical body of the claw 1 is divided into two asymmetric sections by the slope 4 of the claw. The cylinder is not long. Compared with the drill pipe, the ratio is extremely small and the diameter is maintained. Teeth 3 are made of alloy material, and one-third of the gauge teeth 3 are set on the upper end of the claw body's claw slope 4 highest point. In this example, three lower ends are provided with two-thirds of the gauge teeth 3. In this example Set 6 gauge teeth 3, that is, set 6 gauge teeth 3 at the lower part of the claw 1 anti-nozzle 2 outlet, the gauge teeth 3 are radially equiangularly symmetrical, distributed in an axially equidistant straight line, and radially adjacent to two teeth The axial spacing is less than or equal to the diameter of the addendum circle of the gage tooth 3, which is sligh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com