Double-layer bridge structure capable of lowering integral height

A bridge structure and overall height technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as unsatisfactory needs, high technical difficulty of long-span bridge structures, increase of overall building height, etc., to achieve a clear and reliable way of bearing force, The construction technology is convenient and mature, and the effect of shortening the length of the bridge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

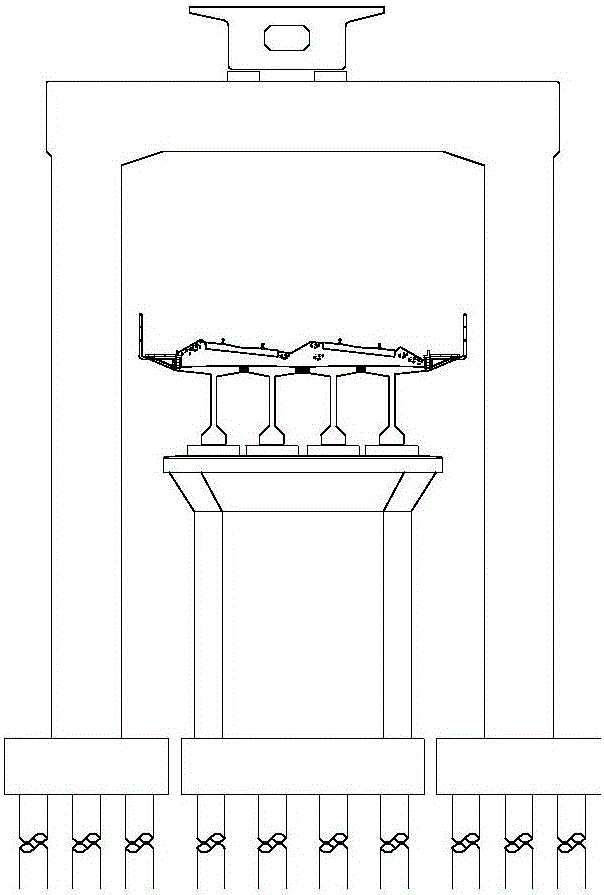

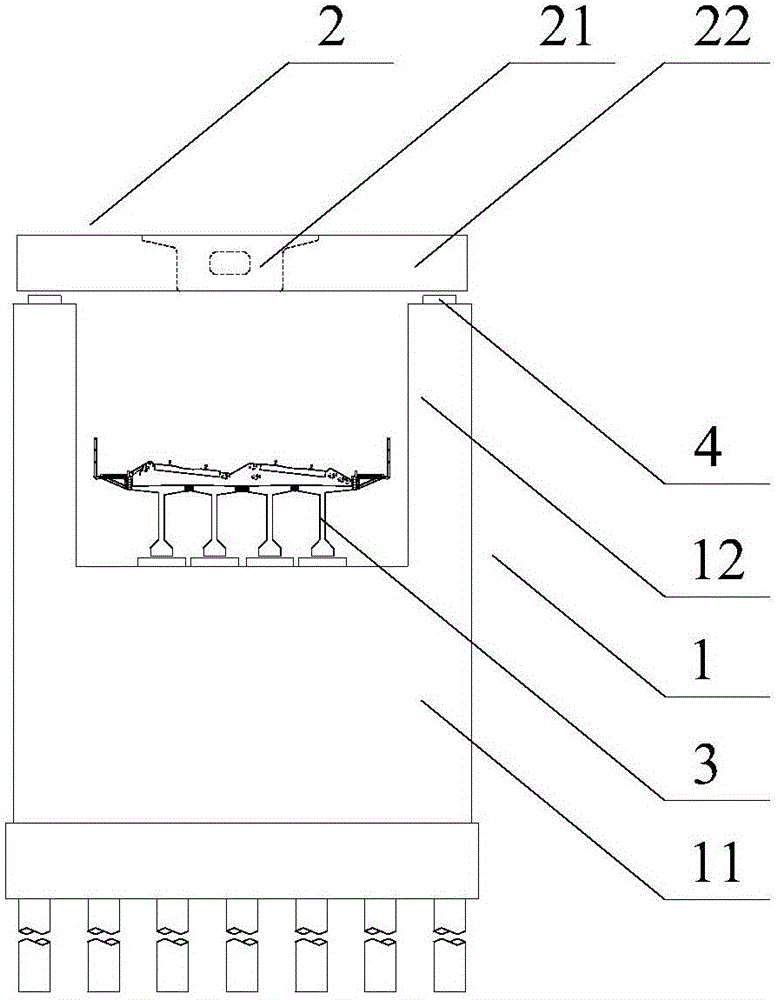

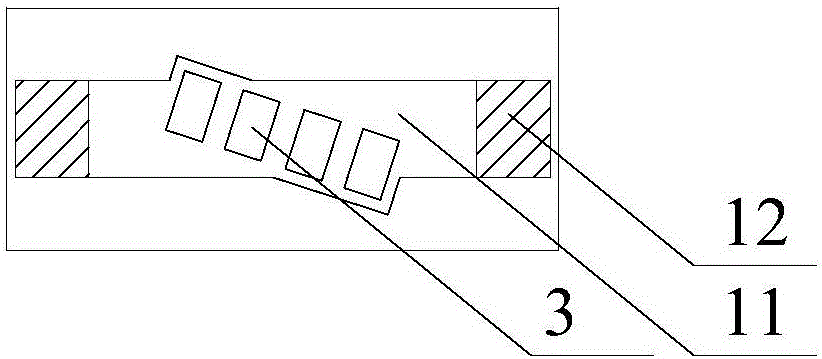

[0019] Such as figure 2 As shown, a double-layer bridge structure with reduced overall height includes a common pier column 1, an upper railway beam part 2 and a lower railway beam part 3, and the common pier column 1 is composed of a lower solid pier 11 and an upper double-column pier 12 One-piece structure, the upper double-column pier 12 is located above the two sides of the lower solid pier 11, such as image 3 and Figure 4 As shown, the lower railway beam part 3 is horizontally arranged on the upper surface of the lower solid pier 11, and the central axis of the lower railway beam part 3 intersects the central axis of the lower solid pier 11 non-perpendicularly, and the upper end surfaces of the upper double-column pier 12 are provided with supports...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com