Monitor Height Adjustment Mechanism

A height adjustment mechanism and display technology, which is applied in the direction of supporting machines, mechanical equipment, machine tables/supports, etc., can solve the problems of locking force failure, troubles in use and adjustment, inconvenient adjustment methods, etc., and achieve the effect of easy height adjustment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

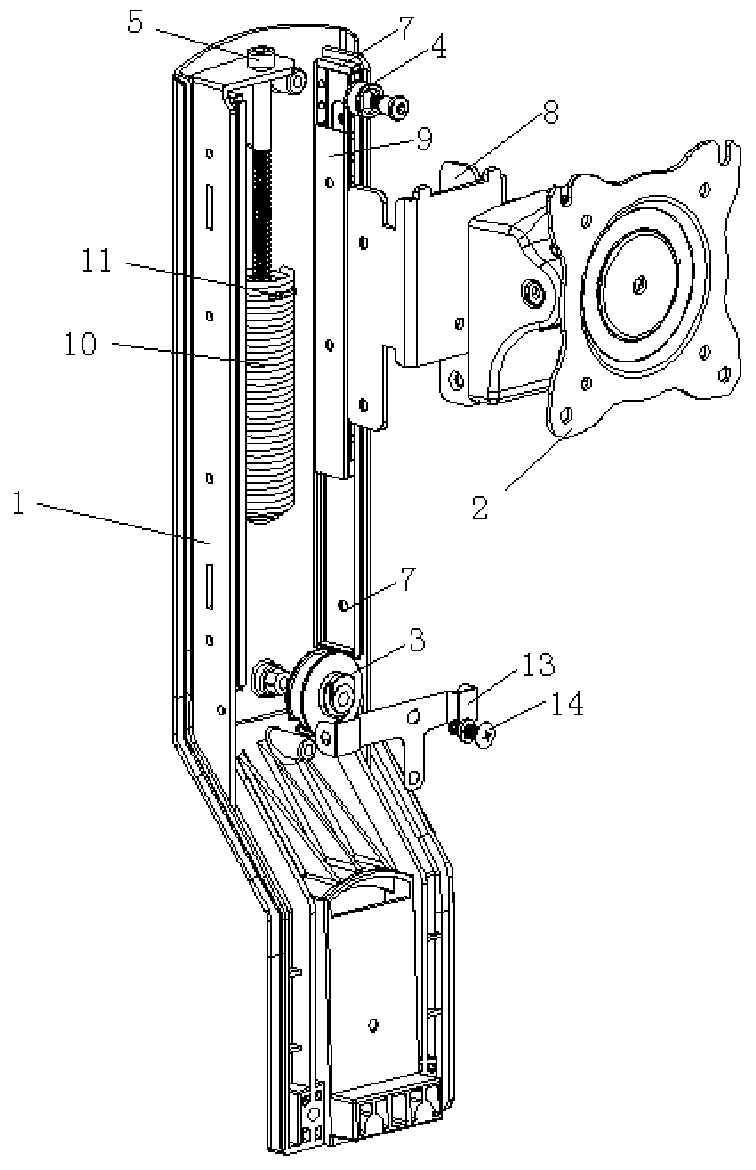

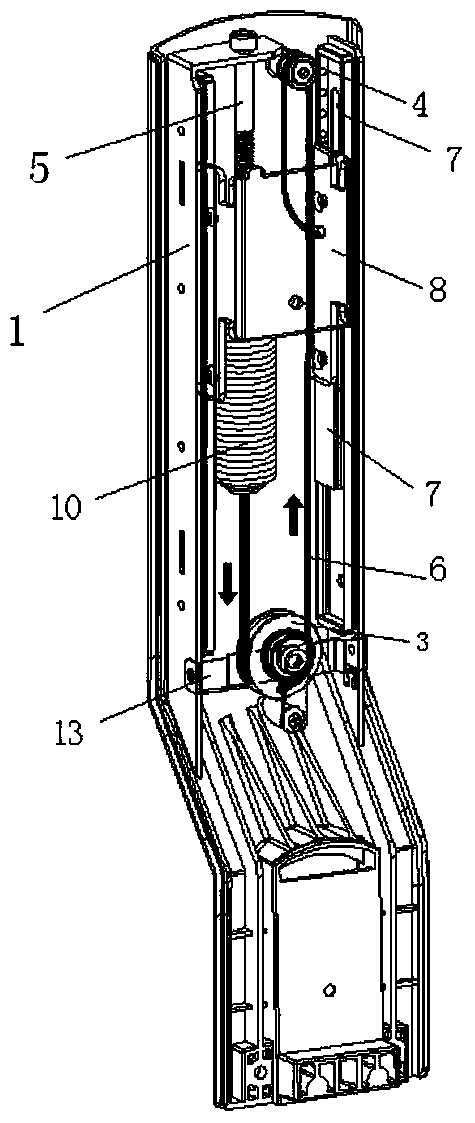

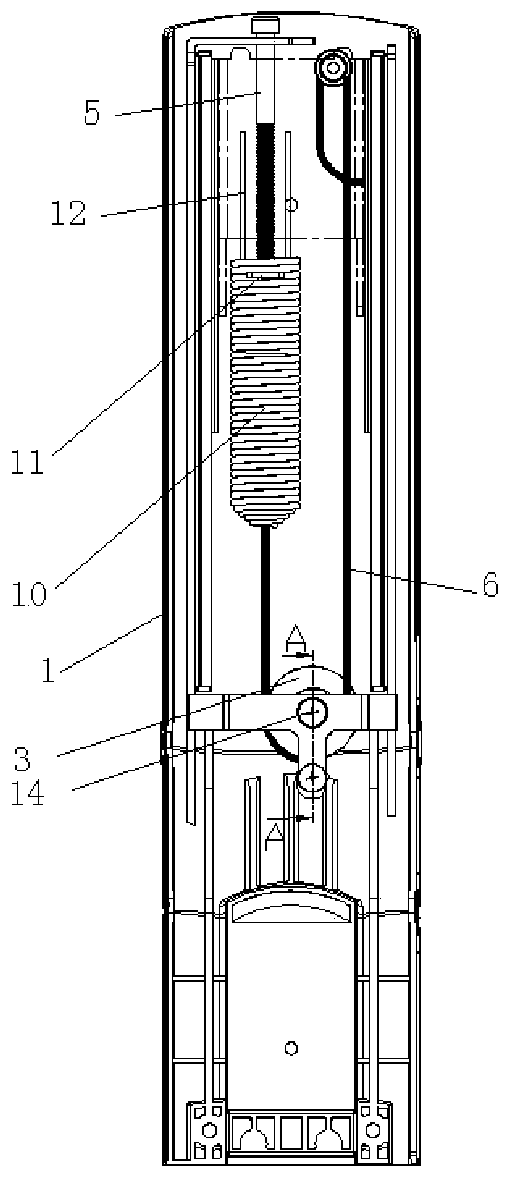

[0020] Embodiment: A display height adjustment mechanism, including a lifting column 1, a turret assembly 2, a variable diameter worm wheel 3, a pulley 4, an elastic member and a rope 6, and the turret assembly 2 can be slid and positioned on the lifting column in the vertical direction 1, the pulley 4 is rotatably installed on the upper end of one side of the lifting column 1, and the variable diameter worm wheel 3 is rotatably installed on the lower end of one side of the lifting column 1, and the wheel groove on the variable diameter worm wheel 3 is gradually formed from one end to the other end. Reduced structure, the upper end of the elastic member is fixedly connected to the upper end of the lifting column 1, the lower end of the elastic member is connected to the upper end of the rope 6, and the other end of the rope 6 closely bypasses the wheel groove of the variable diameter worm wheel 3 and then turns around and then turns around the pulley 4 and finally It is connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com