Variable Stiffness Broadband Resonant Mechanism

A technology of broadband resonance and variable stiffness, which is applied in the field of variable stiffness broadband resonance mechanisms, can solve the problems of narrow resonance frequency range and excessive power at the crossover frequency of fixed stiffness resonance mechanisms, so as to reduce stress and strain, reduce input power, The effect of expanding the amplitude range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

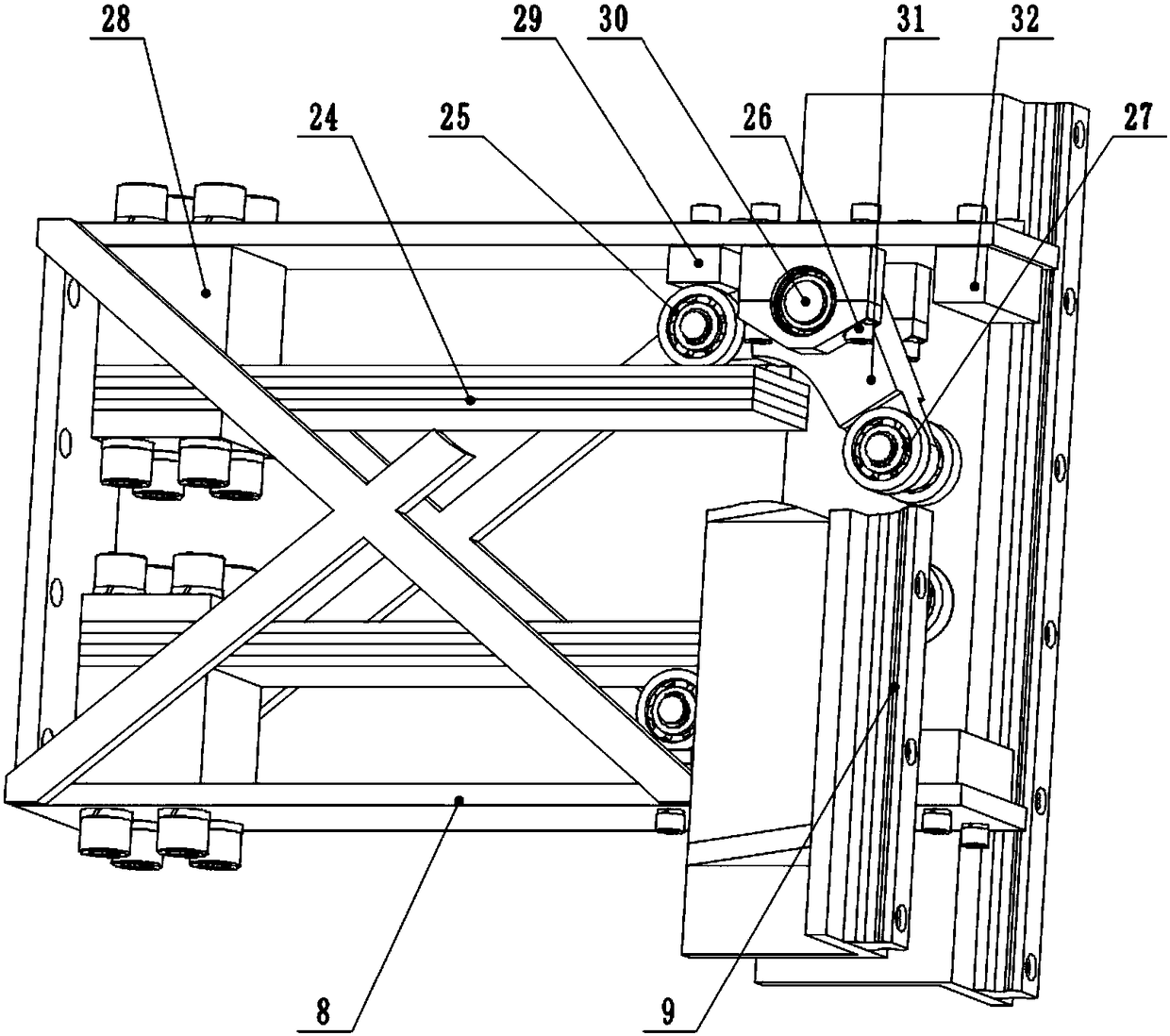

[0089] In this example, the leaf spring 1502 is selected as 200mm in length and 50mm in width. In order to adjust the stiffness, three thicknesses are set to 2.6mm, 3.5mm, and 4.06mm, corresponding to the initial stiffness of 10N / mm, 20N / mm, and 30N / mm. , the angle between No. 1 rod 2105 and No. 2 rod 2104 is 110°, the initial installation angle θ1 is 60°, and θ2 is 10°. The length of No. 1 rod 2105 is 60mm, and the length of No. 2 rod 2104 is 45mm.

[0090] Different initial stiffnesses of leaf spring groups 15 are set respectively, and the output force varies with displacement as shown in Figure 18 As shown, the output stiffness is as Figure 19 as shown,

[0091] Figure 18 It shows the relationship between the force and displacement of the output end when the superimposed stiffness of different leaf springs is different

[0092] Figure 19 The variation trend of the stiffness with the displacement of the variable stiffness mechanism is shown when different leaf spring...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com