Quantitative analysis method for operating conditions of wet desulfurization system

A technology of wet desulfurization and quantitative analysis, applied in the direction of complex mathematical operations, etc., can solve the problems of not being able to clearly explain the total amount of pollutant discharge, not being able to propose one, and not being able to guarantee the accuracy and authenticity of data, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

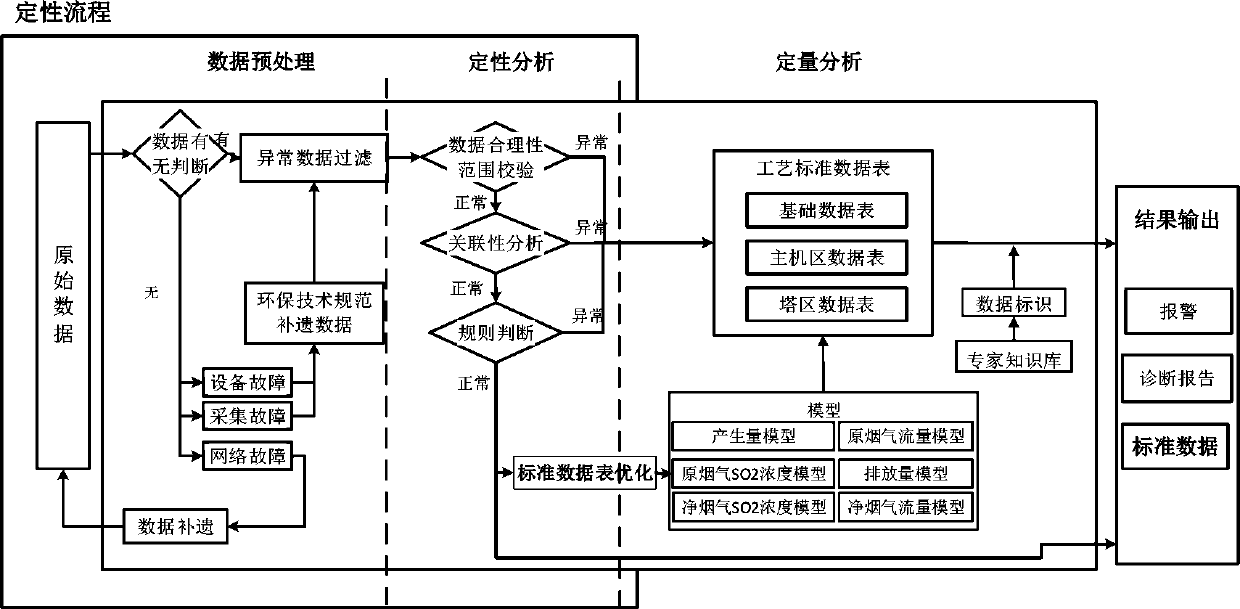

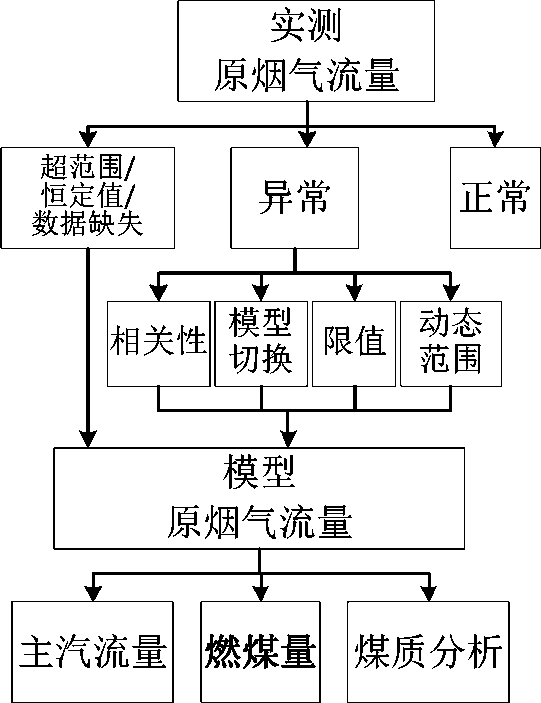

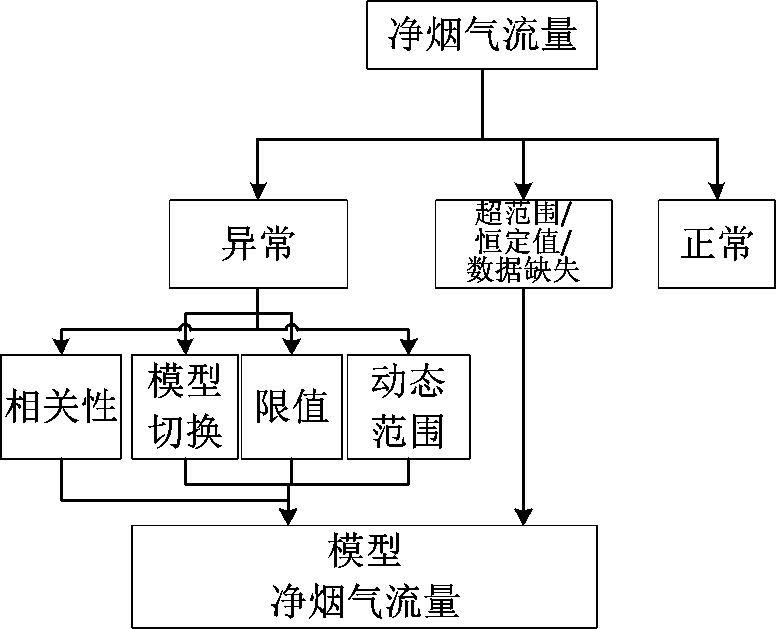

[0063] A working condition quantitative analysis method for the operation of a wet desulfurization system, including collecting unit, FGD, and CEMS data from the DCS system of the power plant through the enterprise service system, collecting, storing and transmitting data through the front end of the working condition, and then uploading , the specific steps are as follows:

[0064] The accounting instrument collects front-end working condition data, directly collects CEMS data, exchanges data with the enterprise service system, and performs qualitative inspection of the process working condition data. If the process data is abnormal, it starts quantitative verification to determine the theoretical emission data. The accounting instrument needs to carry out Compare the outlet data of the working condition with the outlet data of direct mining to determine whether the outlet data has been changed in the DCS, upload the qualitative and quantitative results of the calculator,

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com