Automobile steel wire seat welding device

A welding device and wire technology, applied in auxiliary devices, welding equipment, auxiliary welding equipment, etc., can solve the problems of frame deformation, wire relaxation, low flatness of seat backs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below by means of specific embodiments:

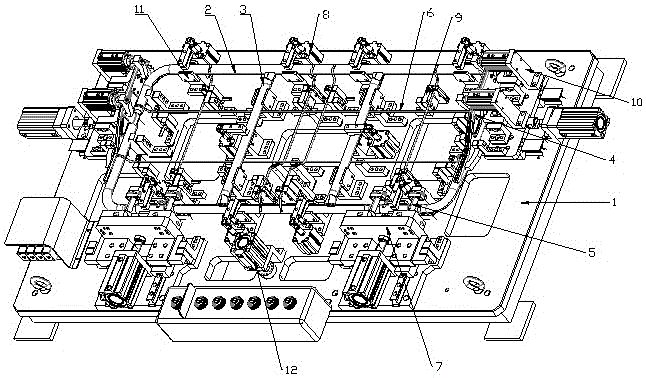

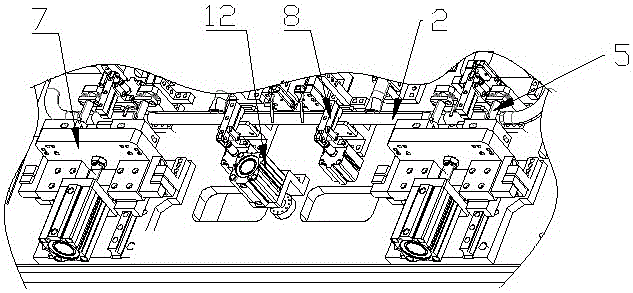

[0028] The reference signs in the accompanying drawings include: base 1, outer frame 2, inner frame 3, side plate 4, headrest tube 5, steel wire 6, headrest tube fixing device 7, frame pressing mechanism 8, steel wire clamping mechanism 9. Side plate clamping device 10, skeleton positioning mechanism 11, control cylinder 12, support seat 13, steel wire positioning mechanism 14.

[0029] The reference numerals of the headrest tube fixing device: the first push cylinder 1301, push plate 1302, mounting block 1303, fixed seat 1304, guide rail 1305, positioning plate 1306, sleeve 1307, coil spring 1308, chute 1309.

[0030]The reference numerals of the frame pressing mechanism: transmission cylinder 1401, frame pressing part 1402, support plate 1403.

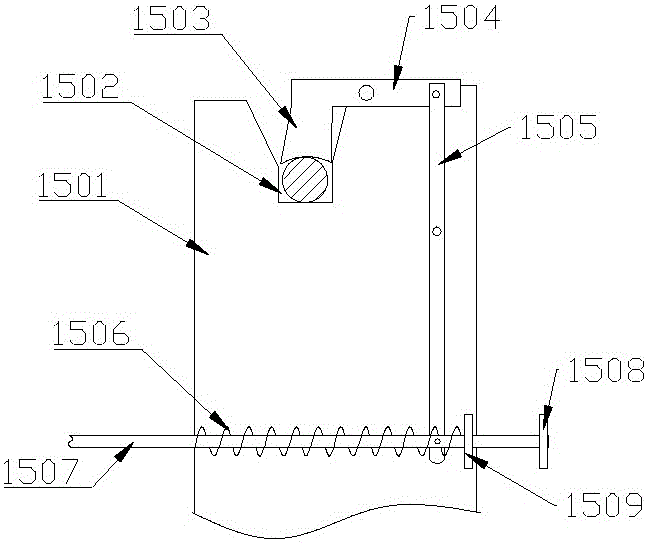

[0031] Reference signs of the steel wire clamping mechanism: positioning base 1501, steel wire positioning groove 1502, clamp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com