Coaxial assembly structure and assembly method thereof

An assembly structure, coaxial technology, applied in the direction of connecting components, metal processing equipment, rod connection, etc., can solve the problems of increasing the production cost of coaxial assemblies, large quantities, and high production costs of assemblies, and achieves a convenient assembly process and reduces costs. Production cost, the effect of ensuring manufacturing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

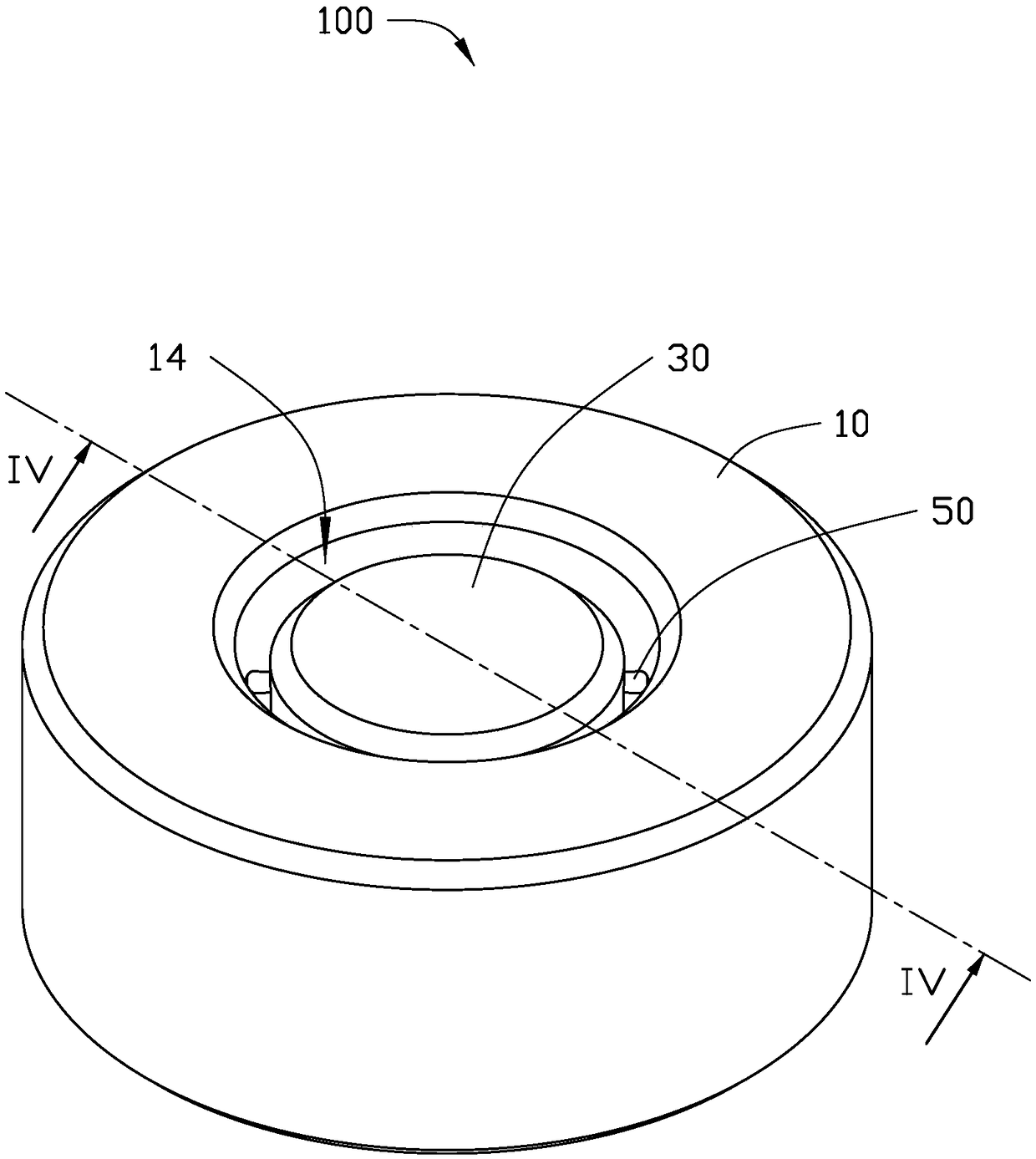

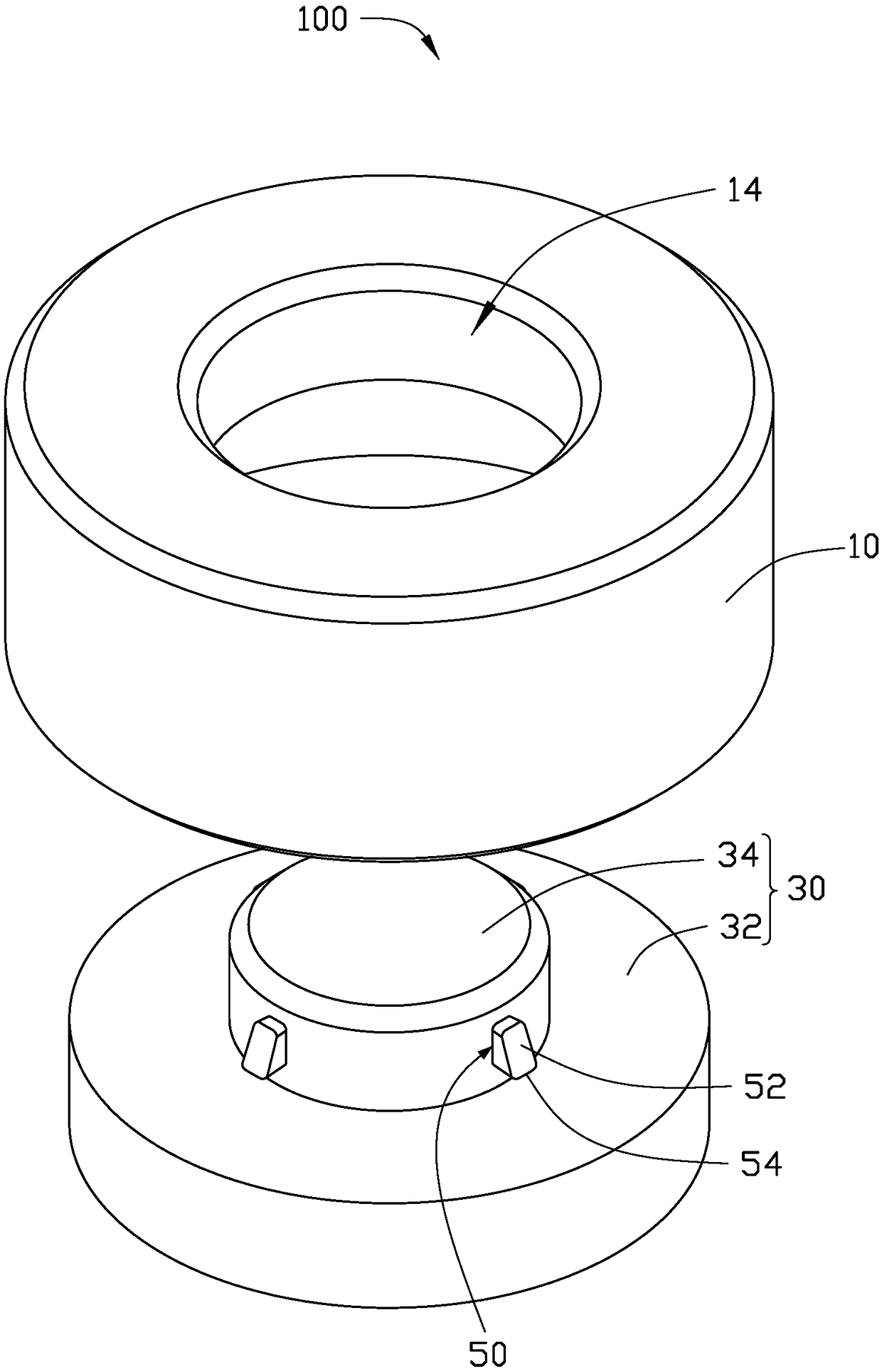

[0025] see figure 1 and figure 2 , the coaxial assembly structure 100 provided by the embodiment of the present invention includes a first assembly 10 , a second assembly 30 accommodated in the first assembly 10 , and a positioning member 50 disposed on the second assembly 30 . The first assembly part 10 and the second assembly part 30 are coaxially arranged, and the positioning part 50 is located between the first assembly part 10 and the second assembly part 30 to ensure the assembly between the first assembly part 10 and the second assembly part 30 coaxiality.

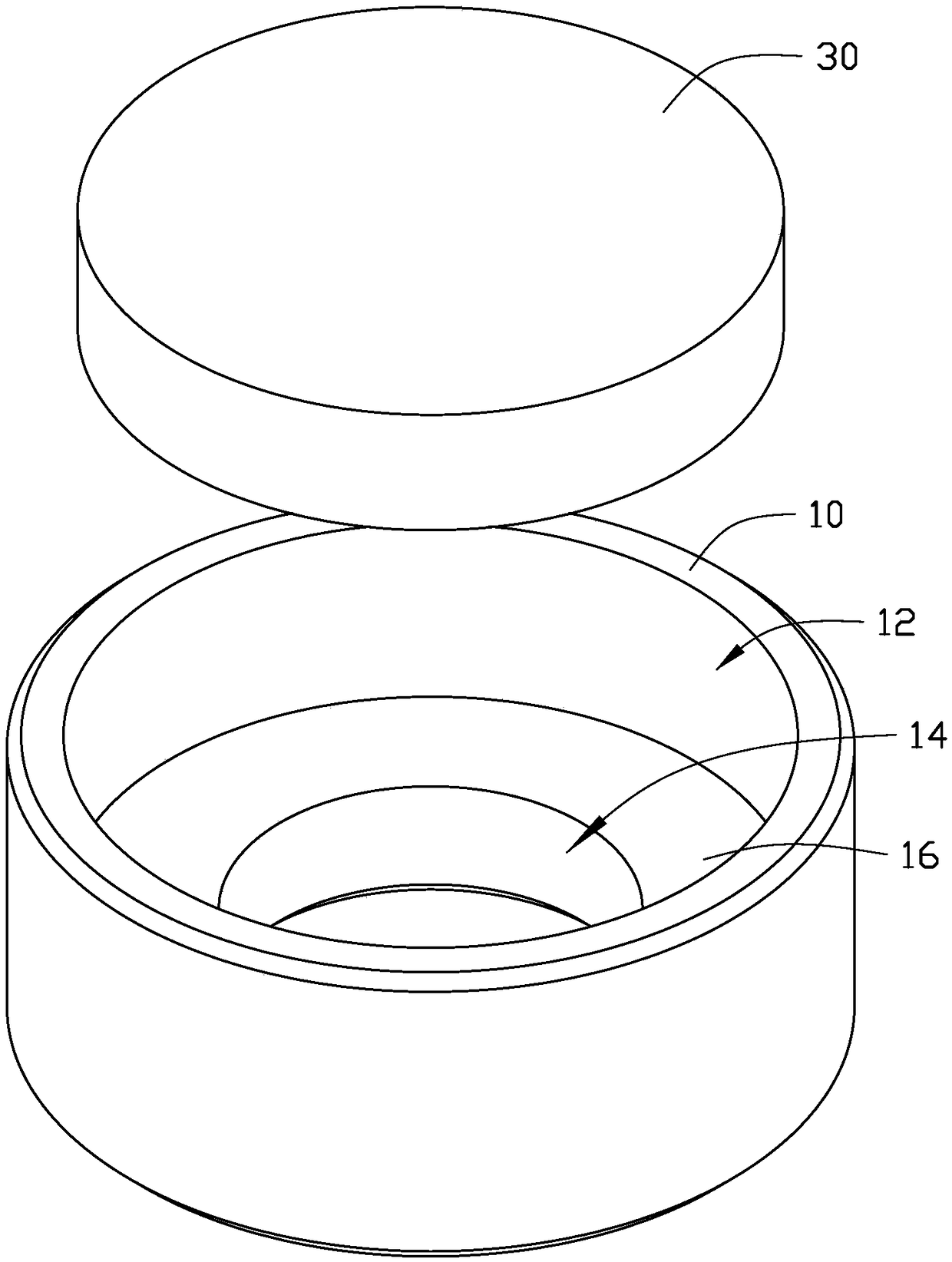

[0026] Please also see image 3 , the first fitting 10 is approximately cylindrical, and has a receiving hole 12 and an assembling hole 14 communicating with the receiving hole 12 along the axial direction.

[0027] The accommodating hole 12 and the assembly hole 14 are substantially coaxially disposed, and respectively pass through two opposite ends of the first assembly part 10 . The diameter of the receiving...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com