Cut-off blade and film roll storage container

A storage container and cutting blade technology, which is applied to the field of cutting blades and film roll storage containers, can solve the problems of insufficient safety and insufficient cutting performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be specifically described below. In addition, the following embodiment is an illustration for demonstrating this invention, and this invention is not limited only to this embodiment. The same reference numerals are attached to the same elements, and repeated explanations are omitted. In addition, in the drawing, the positional relationship such as up, down, left, and right is based on the positional relationship shown in the drawing, unless otherwise specified. In addition, the dimensional ratio of the drawing is not limited to the illustrated ratio.

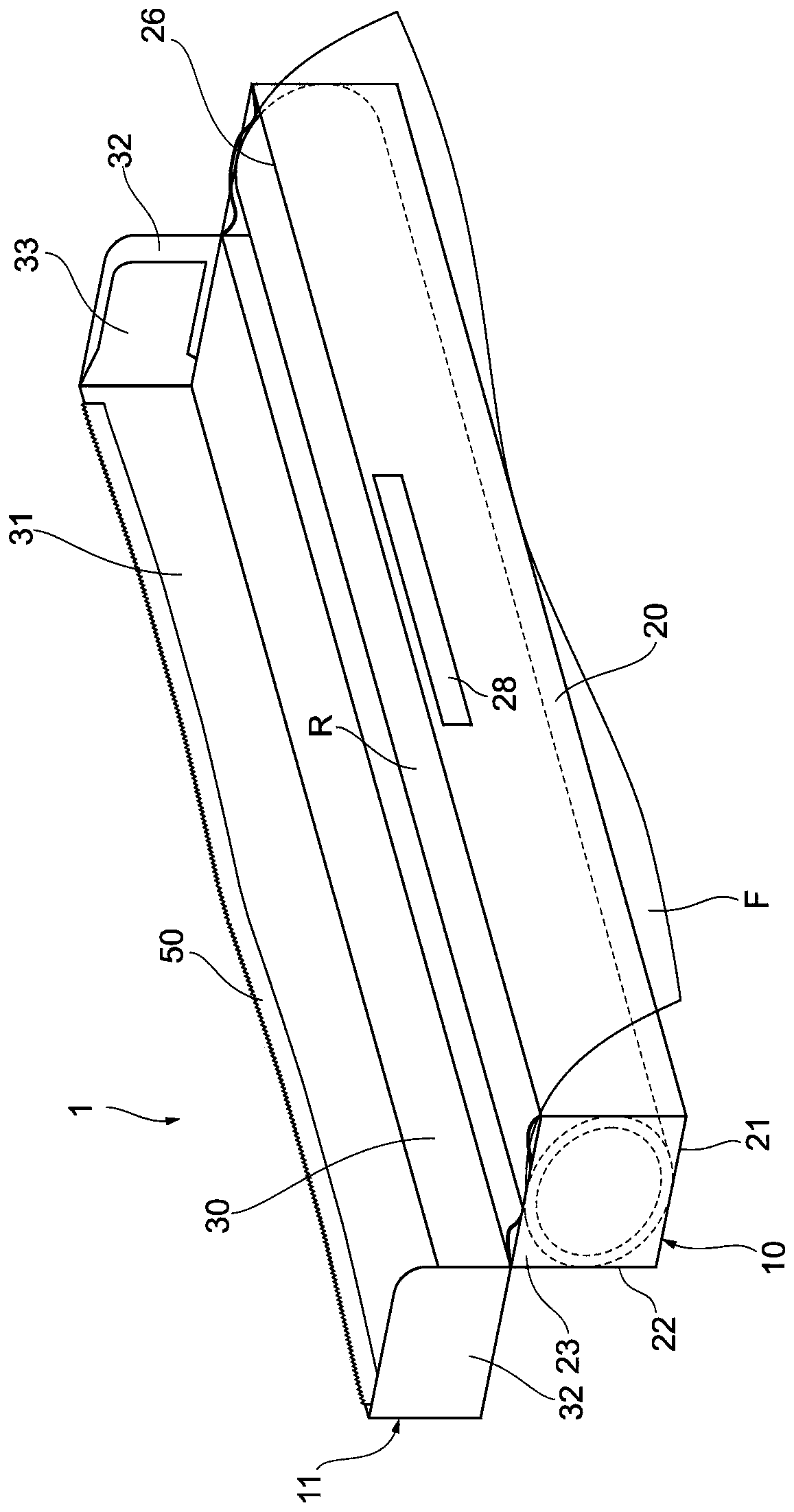

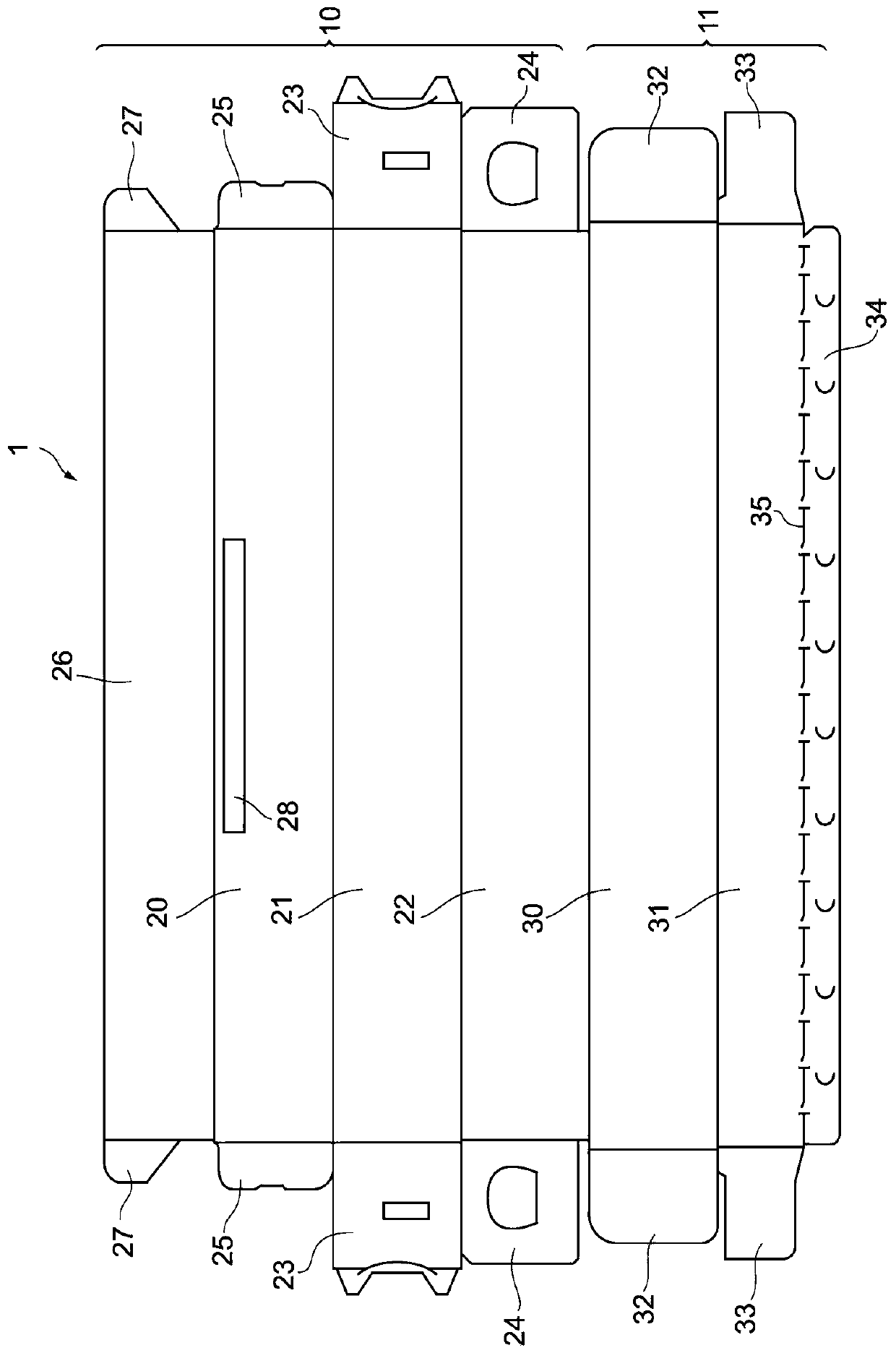

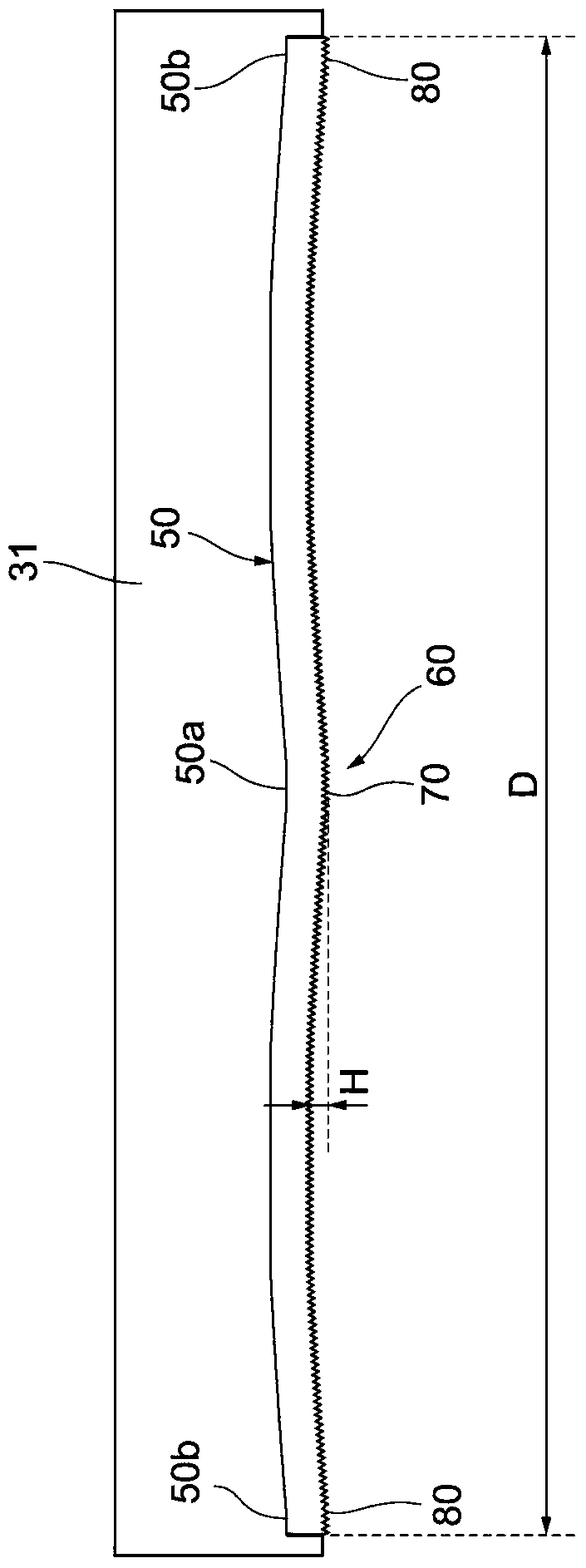

[0022] figure 1 It is a perspective view showing the outline of the film roll storage container 1 having the cutting blade 50 according to the present embodiment, figure 2 yes figure 1 The developed view of the surface side of the film roll storage container 1.

[0023] figure 1 The shown film roll storage container 1 has a storage part 10 which is open on the upper surface and can accomm...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap