A kind of water-based coating liquid of polyester film base coat and polyester film

A technology of water-based coating liquid and polyester film, applied in polyester coatings, coatings, etc., can solve the problems of poor optical properties, weaken the excellent characteristics of optical films, affect the optical properties of polyester films, etc., and achieve improved anti-blocking Effects of properties, smoothness, and excellent optical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example approach

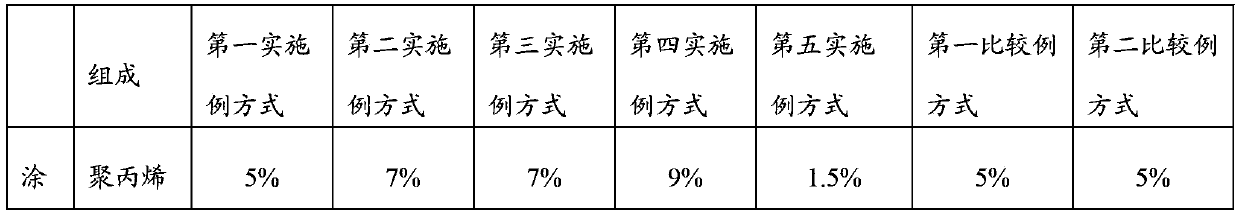

[0057] A polyester film primer aqueous coating liquid, comprising:

[0058] 5wt% of polyacrylic resin, 3wt% of polyester resin, 2wt% of unblockable blocked isocyanate resin, 0.1wt% of nano-scale filler particles, the particle size distribution range is 70-130nm, 0.03wt% of moist Wetting agent, 0.01wt% pH regulator and 89.86wt% deionized water.

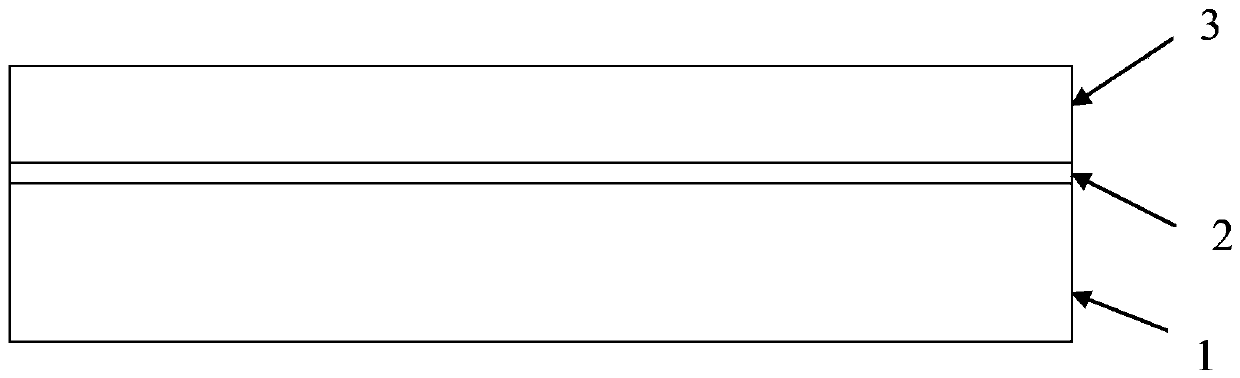

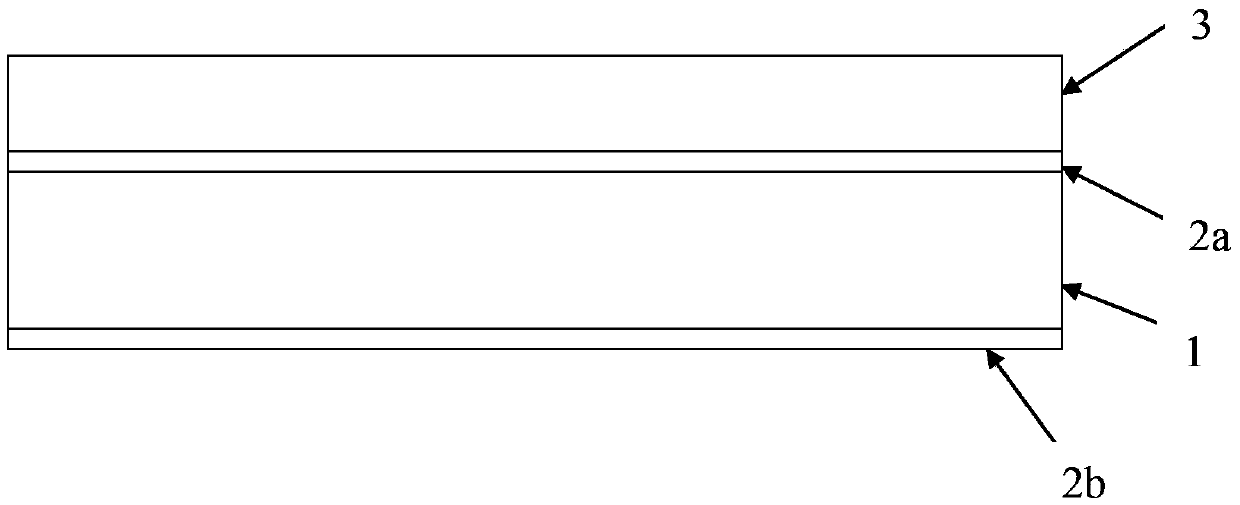

[0059] A polyester film, comprising a polyester film substrate, and an undercoat layer formed by coating one surface of the polyester film substrate with an aqueous coating solution, wherein the aqueous coating solution adopts the above-mentioned method in this embodiment. Water-based coating solution for polyester film base coat;

[0060] Among them, the polyester film adopts the online coating method, and the specific coating process is mainly as follows:

[0061] Stir the above coating solution evenly and apply it on a single surface of the longitudinally stretched sheet of polyester film, then enter the transversely stretched reg...

no. 2 example approach

[0065] A polyester film primer aqueous coating liquid, comprising:

[0066] 7wt% polyacrylic resin, 1.5wt% polyester resin, 2.2wt% unblockable blocked isocyanate resin, 0.1wt% nano-scale filler particles, the particle size distribution range is 70-130nm, 0.03wt% Wetting agent, 0.01wt% pH regulator and 89.16wt% deionized water.

[0067] A polyester film, comprising a polyester film substrate, and an undercoat layer formed by coating one surface of the polyester film substrate with an aqueous coating solution, wherein the aqueous coating solution adopts the above-mentioned method in this embodiment. Water-based coating solution for polyester film base coat;

[0068] Among them, the polyester film adopts the online coating method, and the specific coating process is mainly as follows:

[0069] Stir the above coating solution evenly, then coat one side of the longitudinally stretched sheet of the polyester film, then enter the transversely stretched area for 3.5 times stretching...

no. 3 example approach

[0071] A polyester film primer aqueous coating liquid, comprising:

[0072] 7wt% polyacrylic resin, 1.5wt% polyester resin, 2.2wt% unblockable blocked isocyanate resin, 0.3wt% nano-scale filler particles, the particle size distribution range is 70-130nm, 0.03wt% Wetting agent, 0.01wt% pH regulator and 88.96wt% deionized water.

[0073] A polyester film, comprising a polyester film substrate, and an undercoat layer formed by coating one surface of the polyester film substrate with an aqueous coating solution, wherein the aqueous coating solution adopts the above-mentioned method in this embodiment. Water-based coating solution for polyester film base coat;

[0074] Among them, the polyester film adopts the online coating method, and the specific coating process is mainly as follows:

[0075] Stir the above coating solution evenly, then coat one side of the longitudinally stretched sheet of the polyester film, then enter the transversely stretched area for 3.5 times stretching...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap