Thrust load measuring device for sealed mixing device and calibration method for same

A technology of axial load and measuring device, which is applied in the direction of measuring device, mixer with rotating stirring device, calibration/testing of force/torque/power measuring instrument, etc., which can solve the problems of large scale and complexity of measuring device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

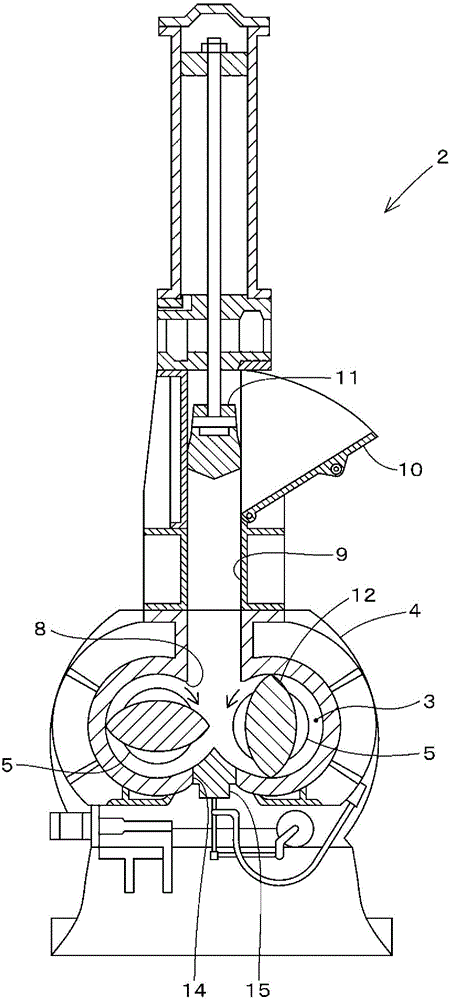

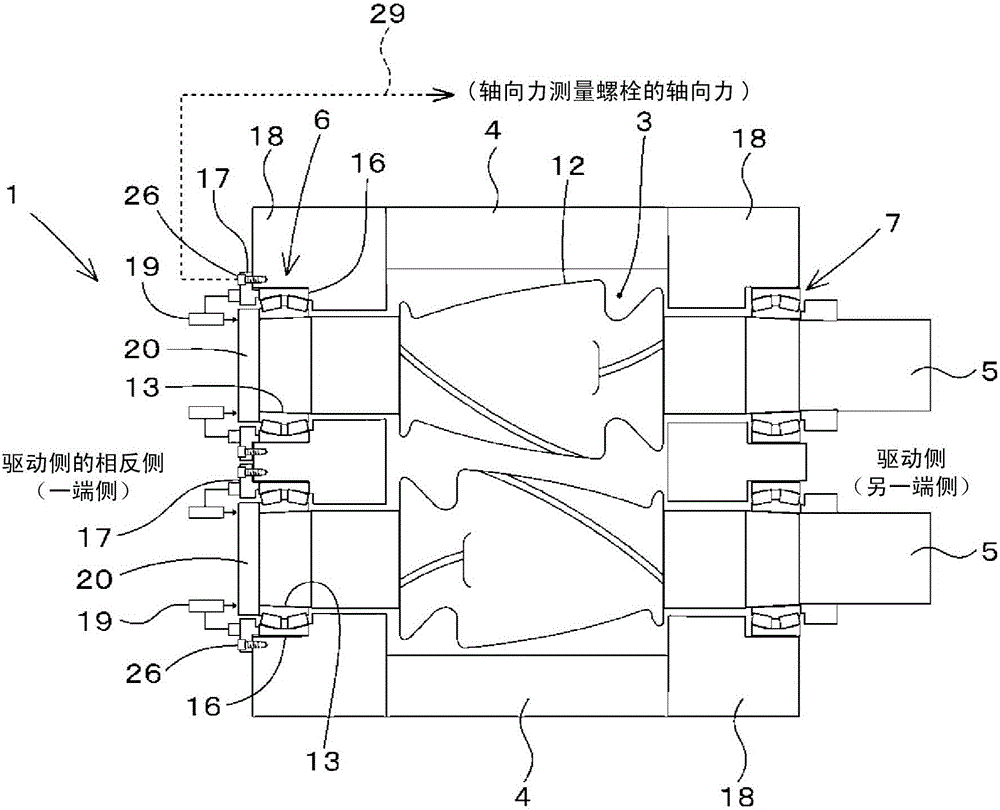

[0033]Hereinafter, the axial load measuring device 1 and its calibration method according to the embodiment of the present invention will be described. First, before describing the calibration method of the axial load measuring device 1 , the closed kneading apparatus 2 provided with the axial load measuring device 1 will be described. figure 1 The closed kneading device 2 of this embodiment is schematically shown. Such as figure 1 As shown, the closed kneading device 2 of the present embodiment includes a housing 4 having a kneading chamber 3 therein, and a pair of rotors 5 , 5 provided inside the housing 4 . Furthermore, the closed kneading device 2 uses a pair of rotors 5, 5 to knead the materials to be kneaded such as rubber and plastics that are pressed into the kneading chamber 3, and to knead the materials to be kneaded into a desired kneading state. A structure in which material is taken out.

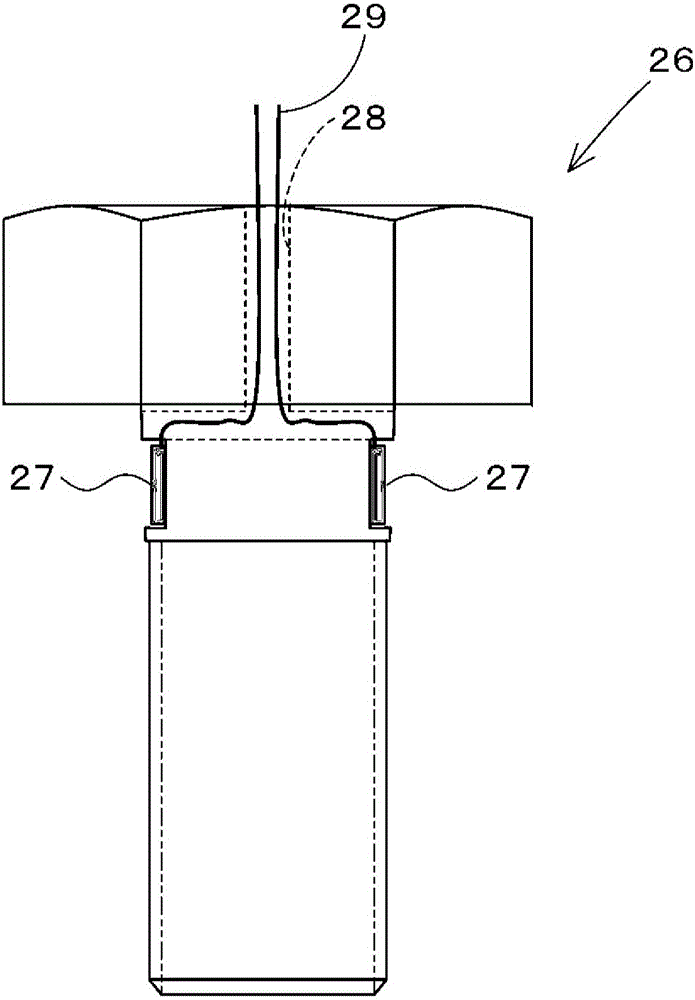

[0034] Such as figure 2 As shown, the pair of rotors 5 , 5 are rotatab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com