Polyester hydrogels

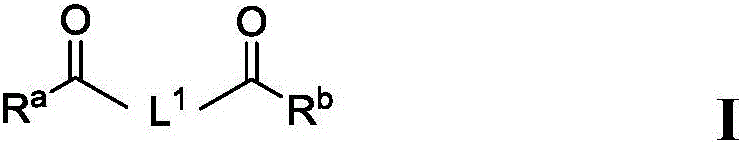

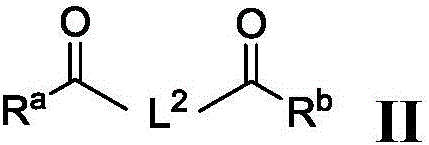

A technology of polyester and cross-linked polyester, used in biocides, plant growth regulators, animal husbandry, etc., can solve the problems of agricultural applications of cross-linked polyester that are not disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

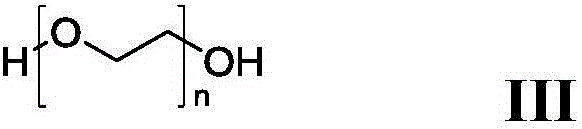

[0278] a) Preparation of unsaturated polyester

[0279] 88.3 g of maleic anhydride, 918 g of Pluriol E6000 (polyethylene glycol with Mn of 6000), 79.3 g of diethylene glycol and 0.75 g of tetrabutyl orthotitanate were reacted at a temperature of 180° C. for about 2 hours, whereby water was distilled off. The temperature was then raised to 200°C and vacuum was applied. The resulting polyester had a hydroxyl value of 31 mgKOH / g and an acid value of 25 mgKOH / g.

[0280] b) preparation of cross-linked polyester

[0281] Heat treatment of the unsaturated polyester according to 1 a) at a temperature of 200° C. under vacuum gives a crosslinked polyester. The crosslinked polyester was then stored in a dry box for 24 hours.

Embodiment 2

[0283] a) Preparation of polyester

[0284] 11.8 g of maleic anhydride, 120 g of Pluriol E4000 (polyethylene glycol with Mn of 4000), 10.82 g of diethylene glycol, and 0.1 g of tetrabutyl orthotitanate were reacted at a temperature of 180° C. for about 2 hours, whereby water was distilled off. The temperature was then raised to 200°C and vacuum was applied. The resulting polyester had a hydroxyl value of 28 mgKOH / g and an acid value of 18 mgKOH / g.

[0285] b) preparation of cross-linked polyester

[0286] Heat treatment of the unsaturated polyester according to 2a) under vacuum at a temperature of 200° C. gives a crosslinked polyester. The crosslinked polyester was then stored in a dry box for 24 hours.

Embodiment 3

[0288] a) Preparation of unsaturated polyester

[0289] 11.8 g of maleic anhydride, 126 g of Pluriol E1000 (polyethylene glycol with Mn of 1000) and 0.1 g of tetrabutyl orthotitanate were reacted at a temperature of 180° C. for about 2 hours, whereby water was distilled off. The temperature was then raised to 200°C and vacuum was applied. The resulting polyester had a hydroxyl value of 27 mgKOH / g and an acid value of 19 mgKOH / g.

[0290] b) preparation of cross-linked polyester

[0291] Heat treatment of the unsaturated polyester according to 3a) at a temperature of 200° C. under vacuum gives a crosslinked polyester. The crosslinked polyester was then stored in a dry box for 24 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com