Pulse back-blowing soot cleaning device and its gas ejector and filter device

A technology of pulse back-blowing and dust-cleaning device, which is applied in the fields of pulse back-blowing and dust-cleaning devices and their gas ejectors and filter devices, and can solve problems such as poor anti-deformation ability, poor back-blowing effect of filter tubes, fatigue fracture of filter tubes, etc. Problems, reduce the impact of thermal shock and vibration, improve the air distribution, reduce the effect of blowback cleaning pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

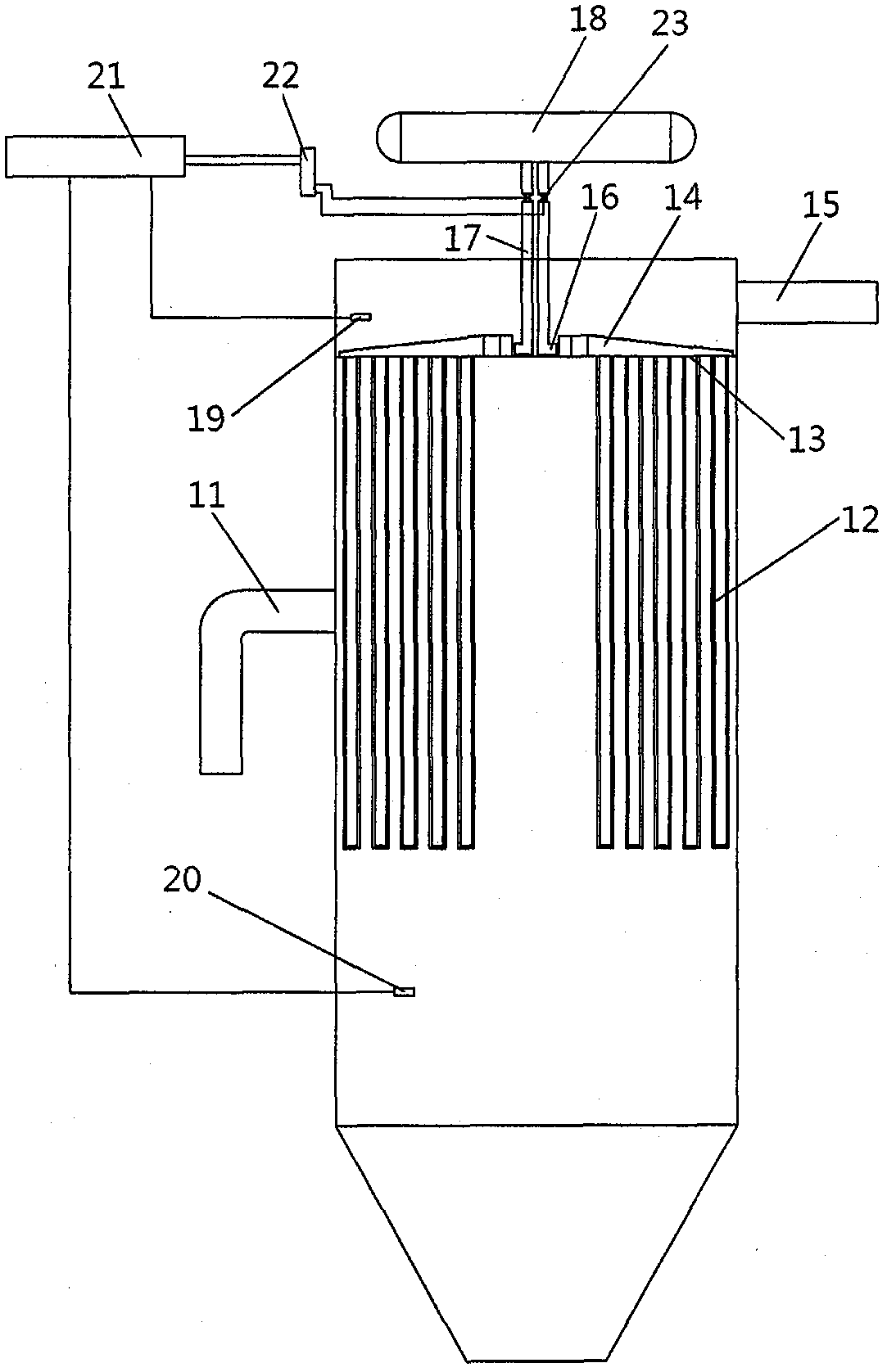

[0023] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

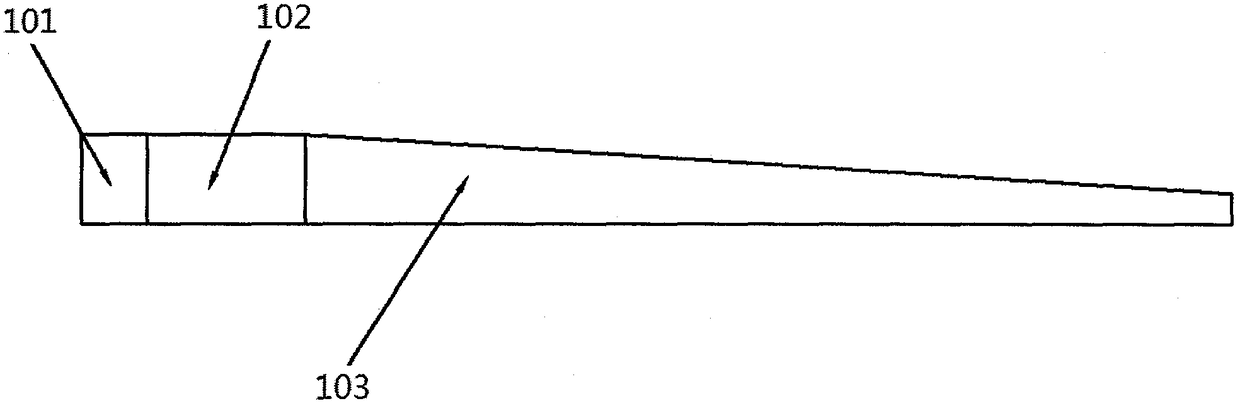

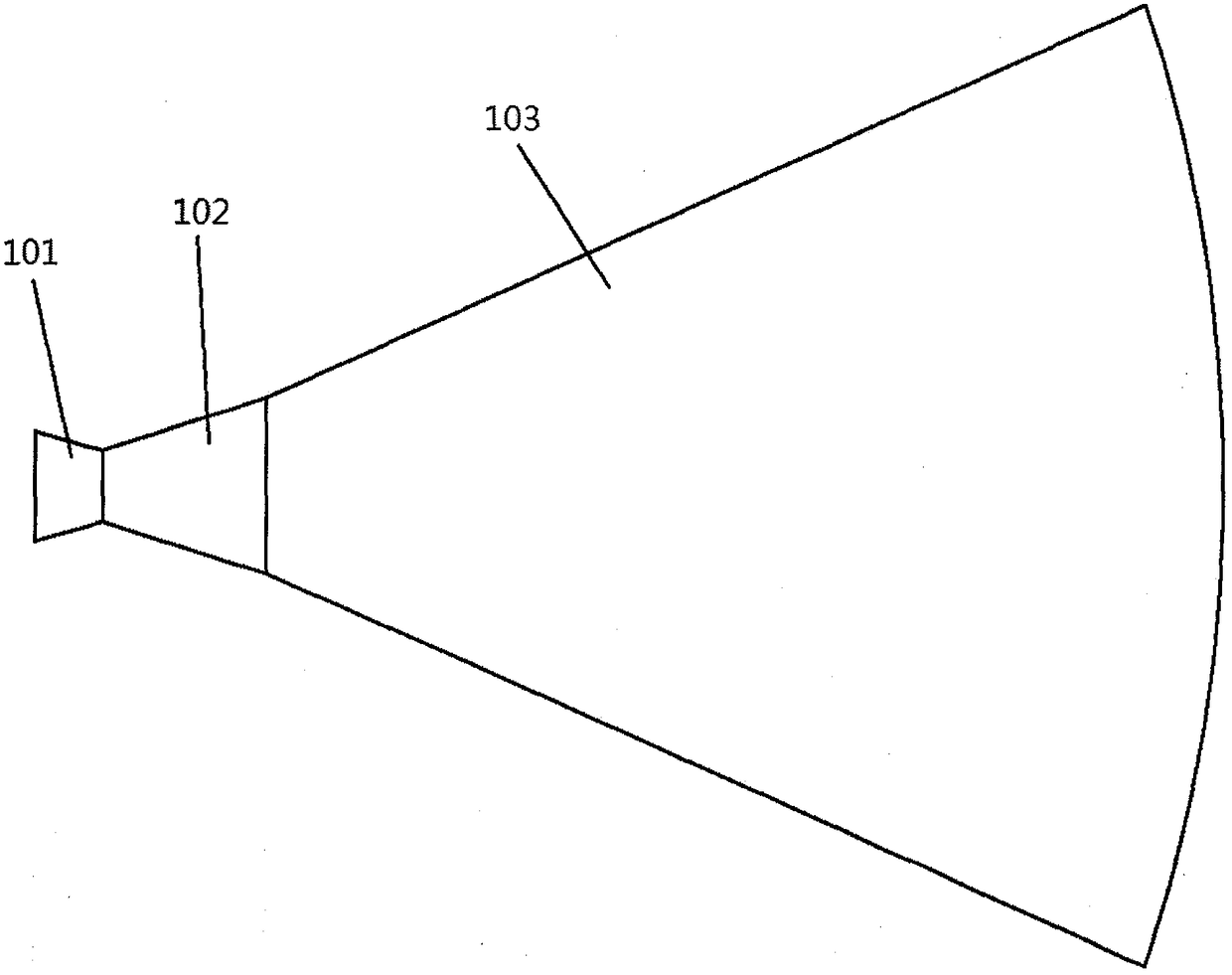

[0024] Figure 1a and 1b A gas ejector of a pulse back-blowing soot cleaning device provided by an embodiment of the present invention. The gas ejector includes an ejector body, and the ejector body includes an inlet portion 101, a neck portion 102 and an inclined portion 103 connected to each other in sequence, wherein the inlet portion 101, the neck portion 102, and the inclined portion 103 are longitudinally sectioned. gradually decreases in height ( Figure 1a The vertical direction shown is the height direction of the gas ejector); multiple output ports of the ejector body are arranged at the bottom of the inclined part, and each output port corresponds to an inlet of an external filter element.

[0025] In this way, the height of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com