Flatness error evaluation method and device

An error evaluation and flatness technology, applied in the field of flatness error evaluation method and device, can solve the problems of limited application, complex mathematical model, low calculation efficiency, etc., and achieve the effect of small calculation amount, easy application and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

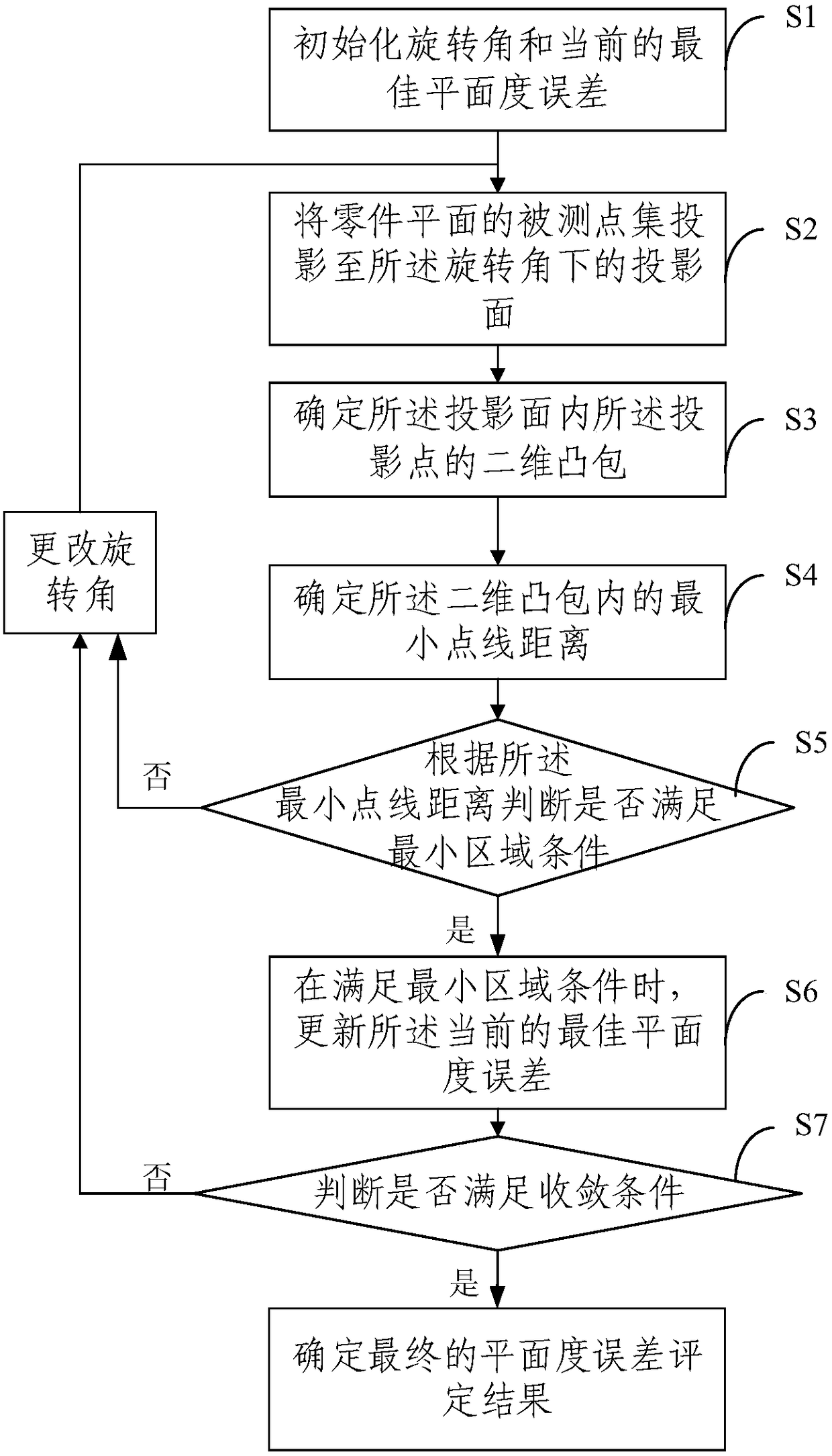

[0066] As another preferred embodiment, the method also includes:

[0067] When the minimum area condition is not satisfied, the rotation angle is changed, and steps S2 to S7 are repeated.

[0068] As another preferred embodiment, the initialization of the rotation angle and the current best flatness error in the step S1 includes:

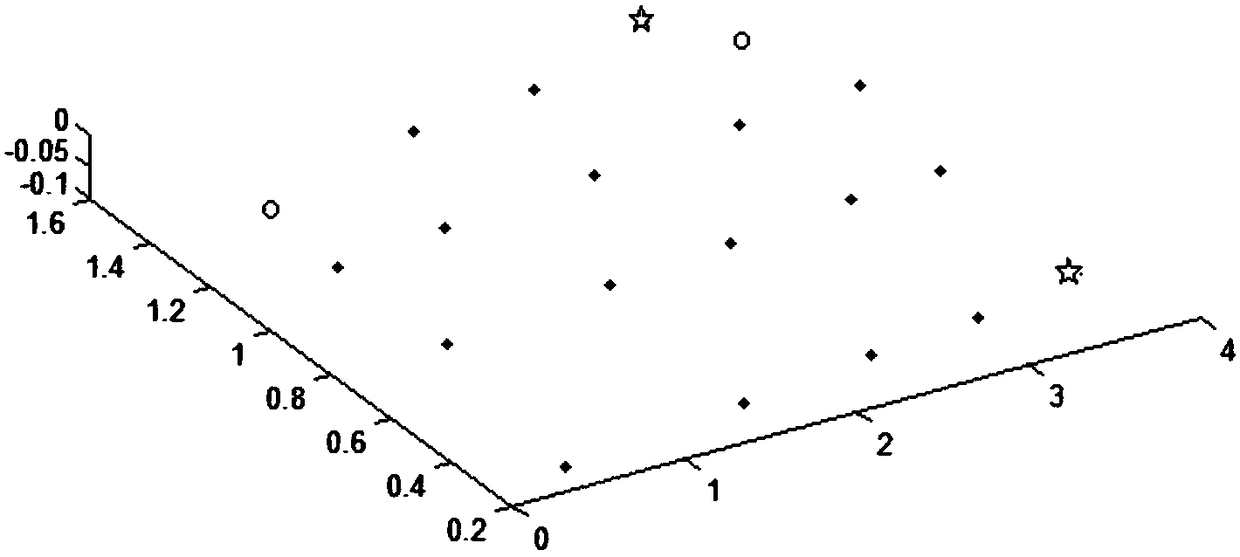

[0069] Measure and obtain the measured point set P of the part plane in the rectangular coordinate system O-XYZ of the measurement space, and express the coordinates of the i-th point in the point set P as P i (x i ,y i ,z i ), and establish a rotation plane S through the z axis, the plane S rotates around the z axis with θ as the rotation angle, and the θ 0 As the iterative initial value of the rotation angle, and let the current best flatness error f best is 0;

[0070] Wherein, the coordinate system O-XYZ includes x-axis, y-axis and z-axis, i=1, 2,...,n, n is the number of measured points, and n is a positive integer greater than or equal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com