Method and apparatus for long-distance insertion of fiber into capillary tube

A technology of capillary and optical fiber, applied in the direction of optical fiber/cable installation, etc., can solve the problems of difficult fiber introduction into capillary, complex structure of the introduction equipment, high processing cost, etc., and achieve the effect of simple operation, good protection performance and effect, and convenient implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The invention provides a method for long-distance optical fiber penetration into capillary, comprising the following steps:

[0013] (1) After attaching the front end of the optical fiber to the magnetic point, insert it into the capillary;

[0014] (2) Bring the strong magnet close to the magnetic point, and then move the strong magnet forward to drive the optical fiber into the capillary.

[0015] In addition, before the step (1), it also includes: putting the optical fiber into a lubricating pool, so that the lubricating mesons are attached to the optical fiber. It can reduce the forward resistance of the optical fiber penetration process.

[0016] In addition, in the step (1), a smooth cap is provided at the entrance of the capillary to prevent the entrance of the capillary from being scratched and damaged.

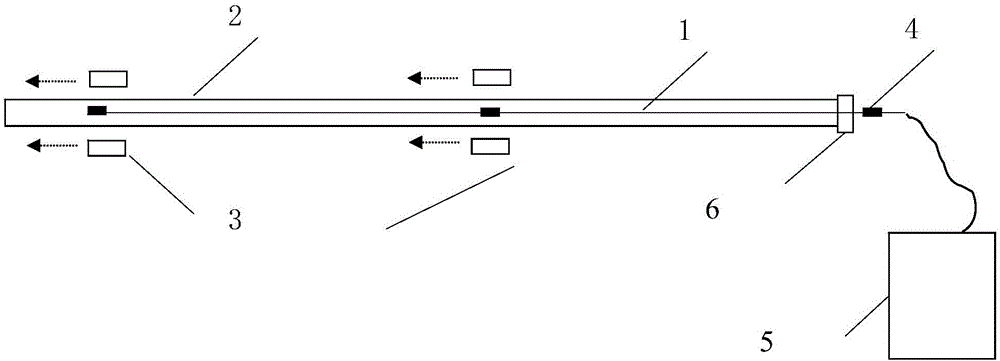

[0017] Also provided is a device for long-distance optical fiber penetration into the capillary, from figure 1 It can be seen from the figure that this long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com