Telescopic prop comprising a spindle, and driving said prop by means of a crown wheel comprising an integrated thrust bearing for supporting loads

A thrust bearing and crown wheel technology, applied in the field of vertical slender brackets, can solve the problems of increasing the total height of the bracket, increasing the weight of the system, and trailer manufacturers having to produce mounting plates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

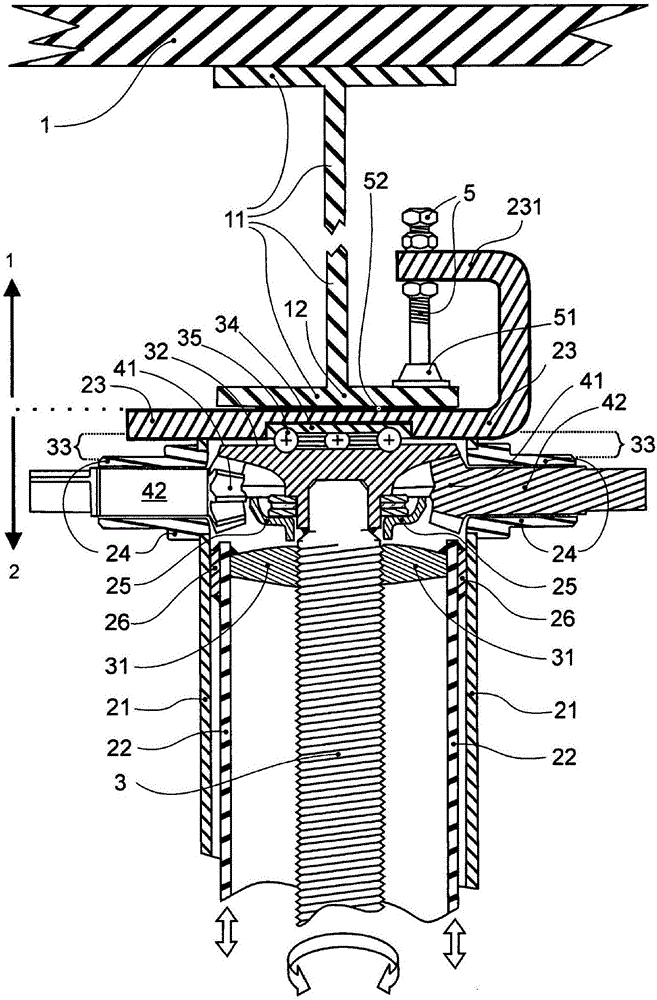

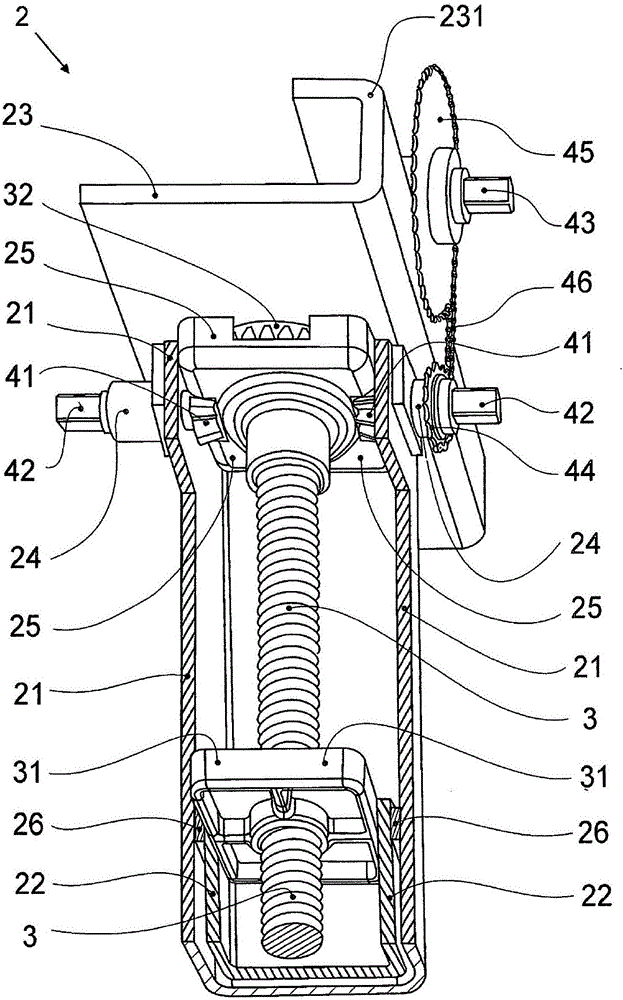

[0075] figure 1 A stand 2 and a vertical section of the vehicle trailer 1 are shown. This section runs through the central axis of the threaded mandrel 3 and only shows the top area from the carriage 2 with the two bevel gears 41 for driving the crown wheel 32 and as a means of moving the second carriage 2 The output of the second bracket 2 is not shown here. For the vehicle carrier 1 , only the section of the load area and the section of the longitudinal beam 11 with the H-shaped profile below it is shown, the lower area of the longitudinal beam 11 —the bottom flange 12 — Stand on stand 2. That is, the bottom flange 12 rests on the cover 23 . This cover 23 is the part of the bracket 2 which closes the strut tube 21 at its top.

[0076] This cover 23 has on its downward facing surface the most important feature of the invention, namely, the upper part of an integrated thrust bearing 33 consisting of a bearing plate 34 into which an annular tread of a plurality of balls 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com