Laminated test tube apparatus convenient for placing test tubes

A layered, test tube technology, applied in the direction of test tube racks/clamps, laboratory equipment, chemical instruments and methods, etc., can solve the problems of multiple test tube racks and occupying space on the test bench, and achieve easy operation, simple structure, and save experiments The effect of table space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

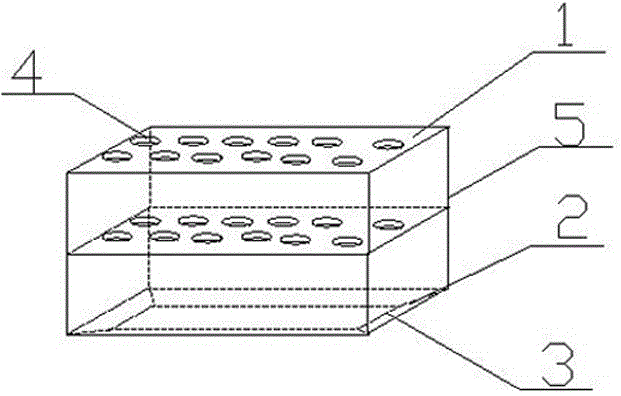

[0022] Such as figure 1 , figure 2 As shown, a stacked test tube device that is convenient for placing test tubes includes a top plate 1, a bottom plate 2, and a middle plate. The four corners of the bottom plate 2 are all provided with connecting parts, between the connecting parts of the top plate 1 and the connecting parts of the middle plate, between the connecting parts of the middle plate and the connecting parts of the bottom plate 2, are all connected by connecting rods 5; It is a cylindrical cavity, and the middle part of the connection part is provided with a partition.

[0023] In this embodiment, the top plate 1 and the middle plate are cuboid plates with a certain thickness, and the top plate 1 and the middle plate are all provided with through holes for placing test tubes, and the top plate 1, the middle plate, and the bottom plate 2 are arranged from top to bottom. Arranged in layers, the top board 1 and the middle board, the middle board and the bottom board...

Embodiment 2

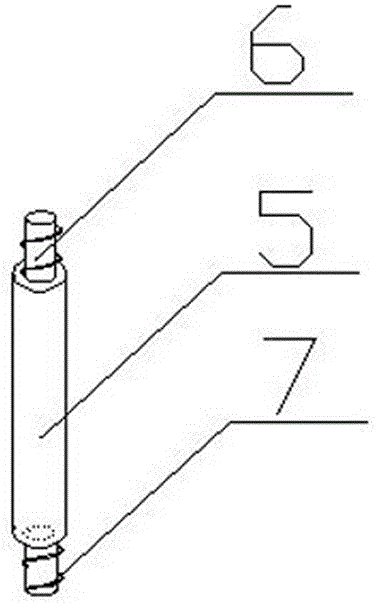

[0026] This embodiment is further defined on the basis of the above embodiments, the two ends of the partition are respectively a first cavity and a second cavity, and internal threads are provided in the first cavity and the second cavity. Both ends of the connecting rod 5 are provided with a first cylindrical rod 6 and a second cylindrical rod 7 respectively, and the first cylindrical rod 6 and the second cylindrical rod 7 are both provided with external threads. Here, the connection mode between the top plate 1 and the middle plate, between the middle plates, and between the middle plate and the bottom plate 2 is specifically limited, and the connection mode of thread adaptation is used to improve the stability of the test tube rack.

Embodiment 3

[0028] On the basis of the above-mentioned embodiments, this embodiment further defines that the top plate 1 and the middle plate are provided with through holes 4, and the center of the through hole on the top plate 1 is at the same center as the center of the through hole on the middle plate. vertical line. When placing, it can be inserted directly from the through hole 4 of the top plate 1 into the through hole at the corresponding position of the middle plate or from the through hole of the middle plate into the through hole at the corresponding position of the bottom plate 2 . Therefore, a stacked arrangement can be realized as required.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com