Multi-level stacking combined package sorting-packing-conveying device

A conveying device and multi-level technology, which is applied in the field of multi-level superimposed combined package sorting-packing-conveying devices, can solve the problems of low space utilization, large floor area, high error rate, etc., and achieve reduced workload and occupation The effect of small area and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

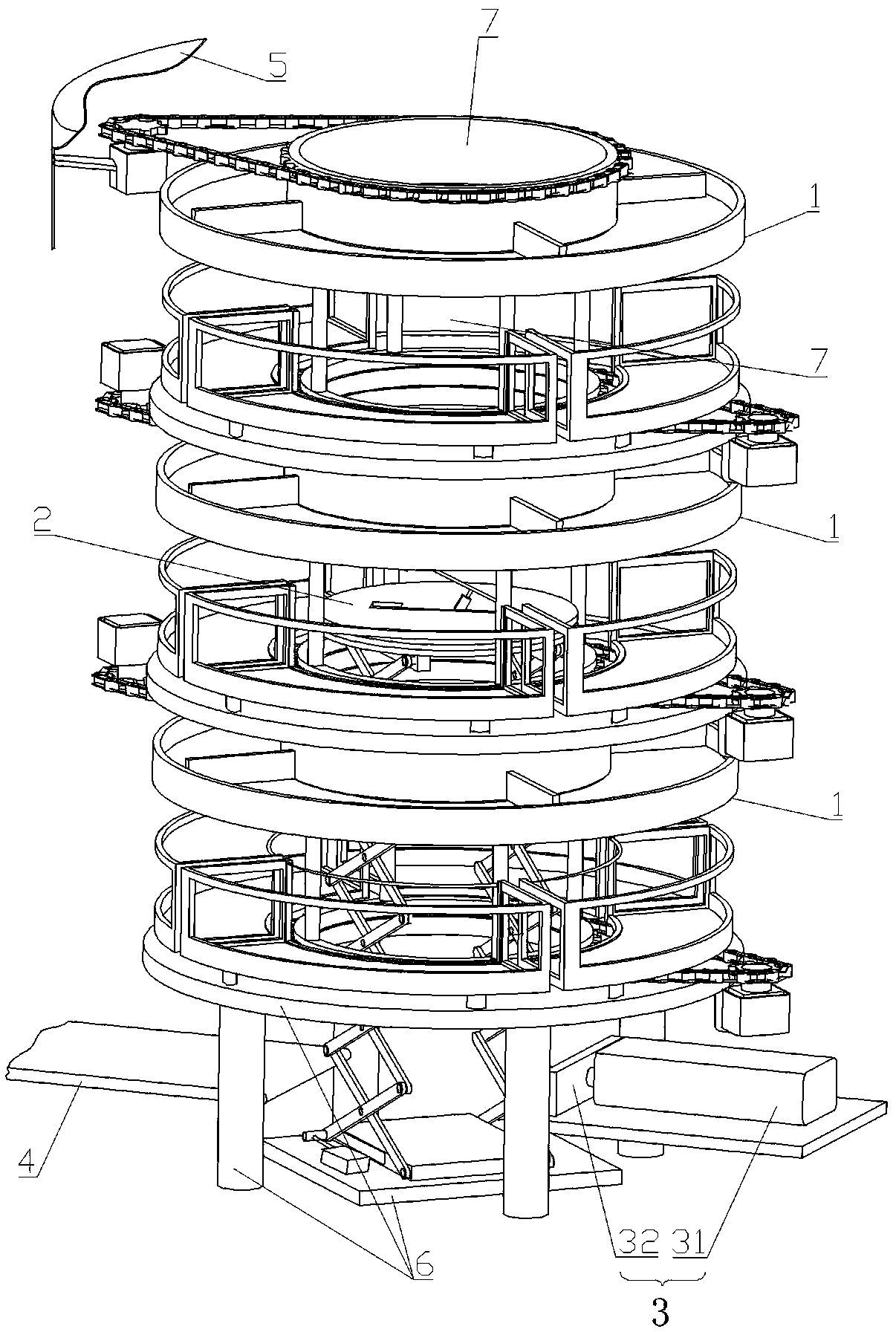

[0065] Such as Figure 1-12 As shown, the multi-level stacked combined parcel sorting-packing-conveying device includes a sorter 1, a wrapper 2, a pusher 3, an output belt 4, an outer cover 5, a base 6 and a controller (not shown in the figure) ).

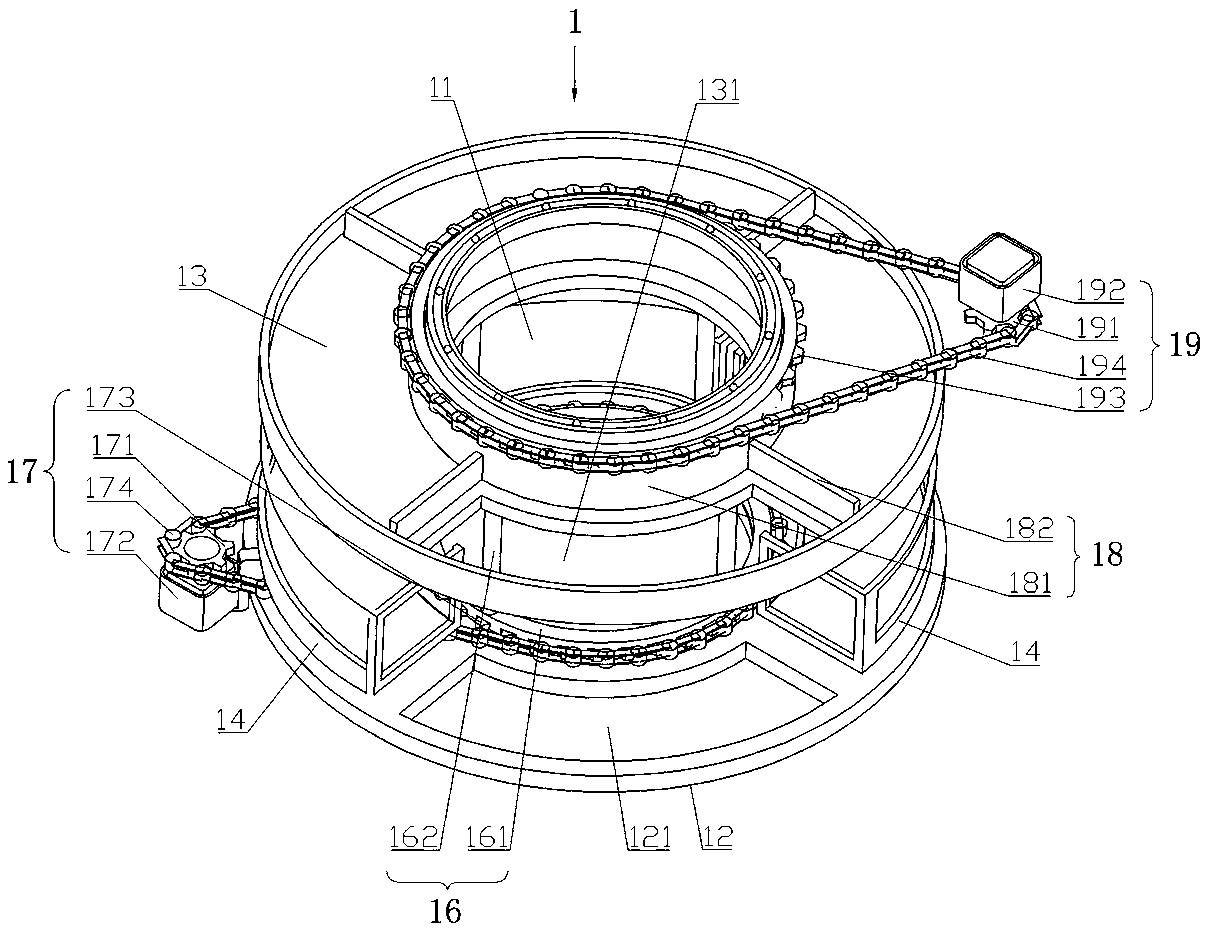

[0066] The sorter 1 includes a bottom plate 12, a leaky plate 13, a collection box 14, a collection bag 15, a support seat 16, a rotary drive mechanism A17, a shift fork 18 and a rotary drive mechanism B19.

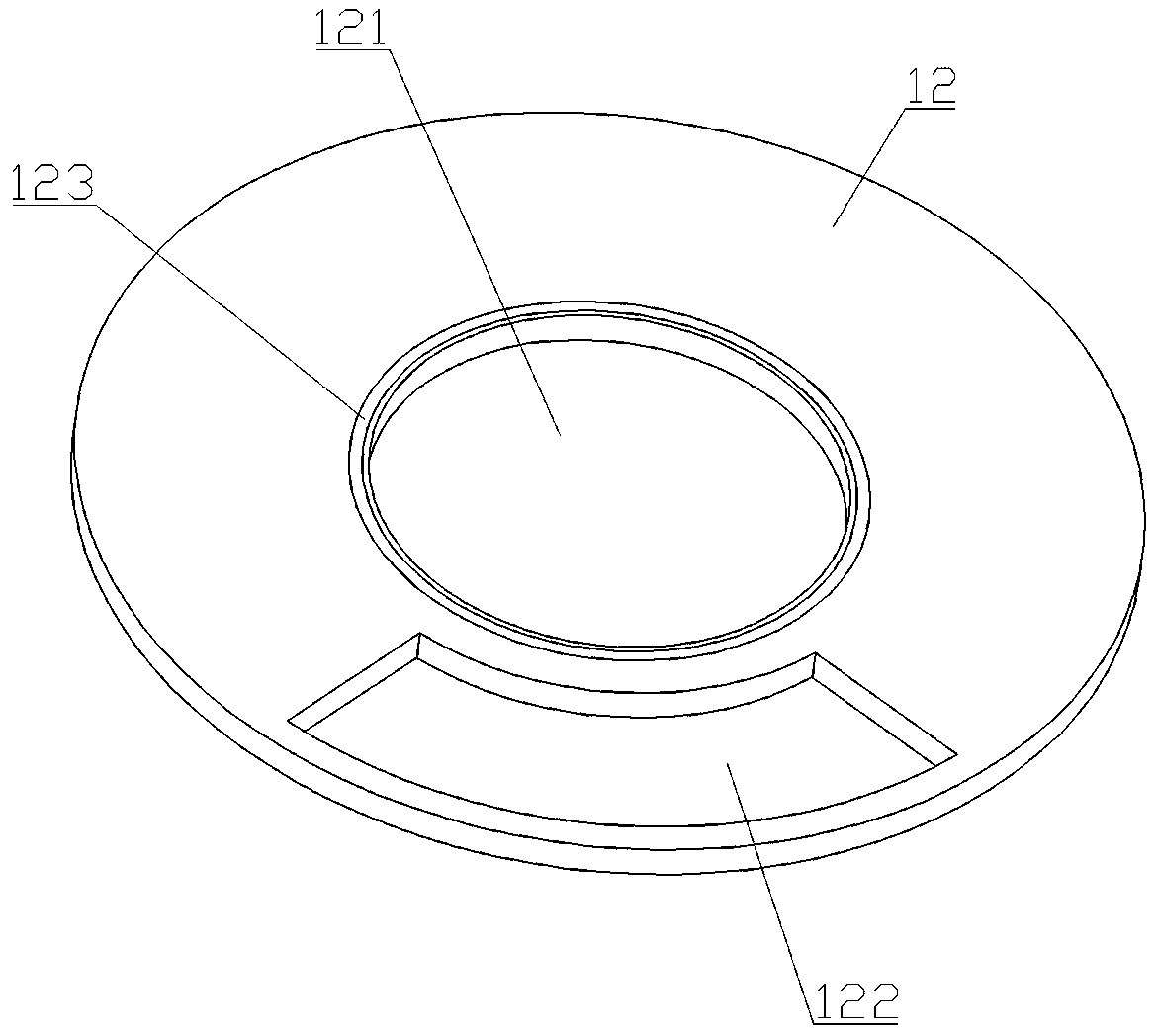

[0067] The bottom plate 12 is an annular plate with a central hole B121 and a package drop hole B122 located outside the center hole B121. An annular groove B123 is provided on the upper end surface between the center hole B121 and the package drop hole B122. The bottom plate 12 directly or indirectly Fixed on the outer cover 5.

[0068] The leaking plate 13 is an annular plate with a central hole A131 and a package drop hole A132 outside the center hole A131, and an annular groove A133 is provided on its upper end surface b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com