Patents

Literature

41results about How to "Make full use of the three-dimensional space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

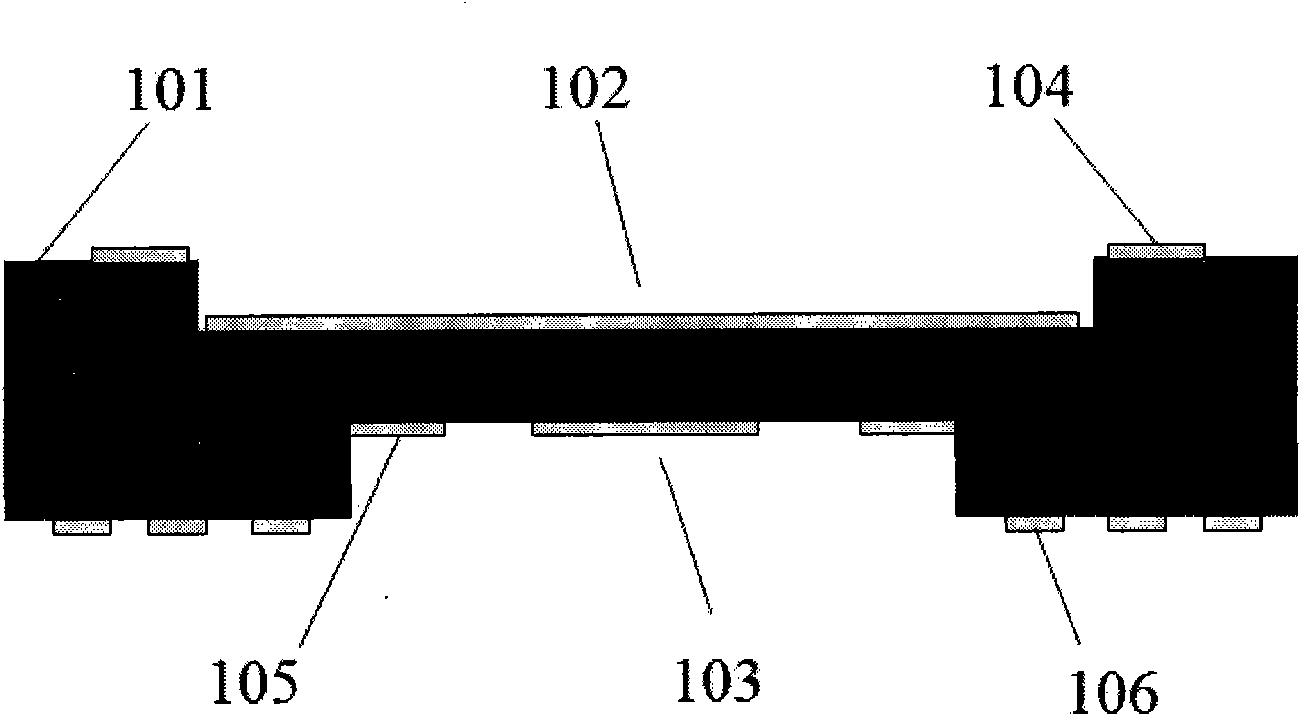

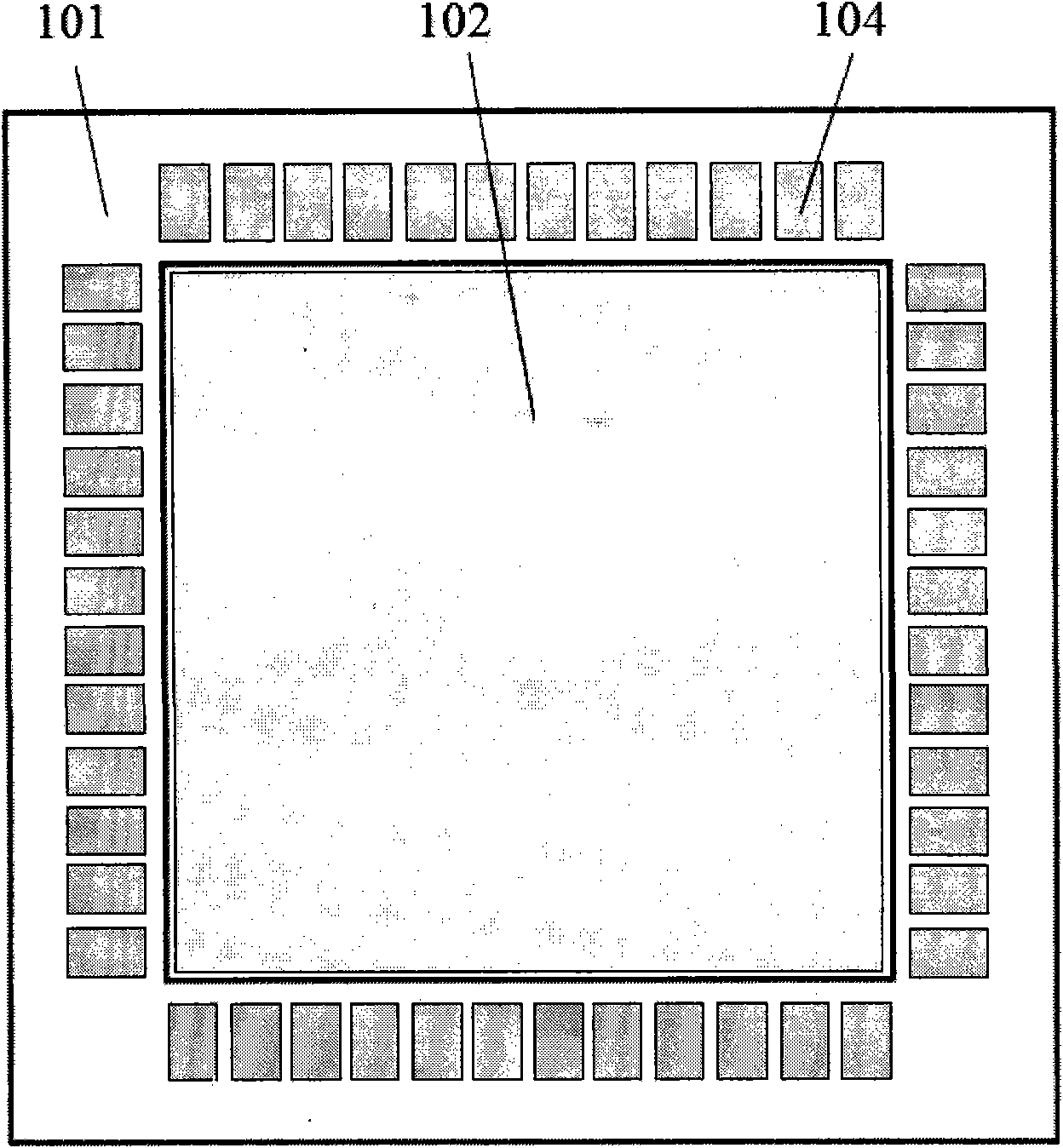

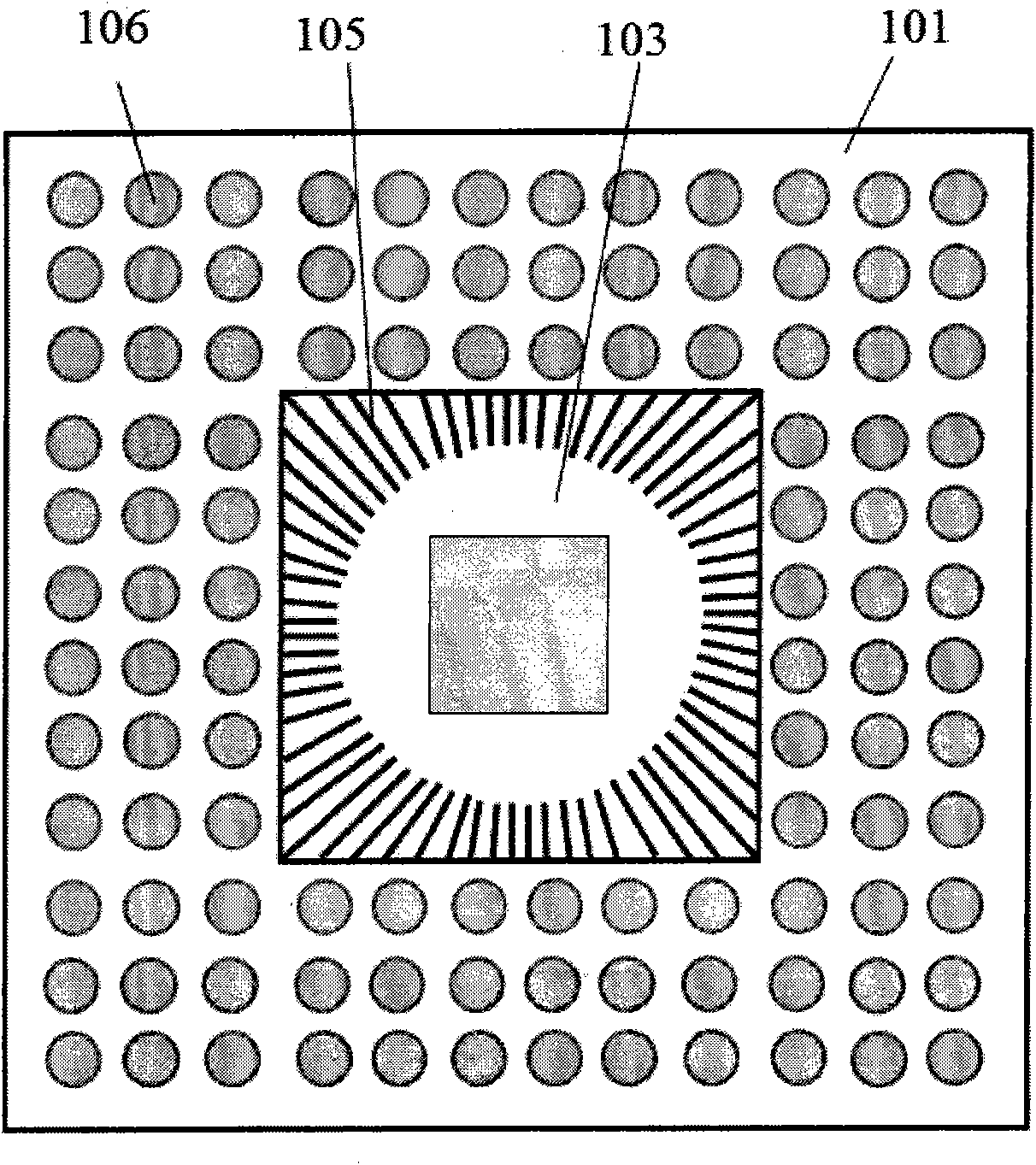

Three-dimensional multi-chip encapsulation module based on buried substrate and method

InactiveCN102163590AProne to warpingAvoid warpingSemiconductor/solid-state device detailsSolid-state devicesHigh densityLead bonding

The invention provides a buried substrate based multi-chip module structure for realizing three-dimensional high-density encapsulation (3D-MCM). The upper surface and the lower surface of the substrate have concave cavity structures; different chips having larger size difference are placed and wires are arranged in the cavity structures having different sizes so as to form a buried three-dimensional encapsulation structure; a plurality of chips are interconnected by using a conventional wire bonding method; a chip protection mode adopts two packing processes, namely sealing glue dropping and surrounding dam packing; a pin output form adopts a peripheral ball grid array mode; and by the concave cavity structures, the encapsulation area is reduced, the encapsulation density is enhanced, the bonded wire is shortened effectively, and the signal delay is decreased. The whole process and the surface assembling process are compatible with each other and have characteristics of simpleness and low cost. By the concave cavity structures on the upper surface and the lower surface of the substrate, the warping of the substrate is decreased and the reliability of the three-dimensional encapsulation structure is improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

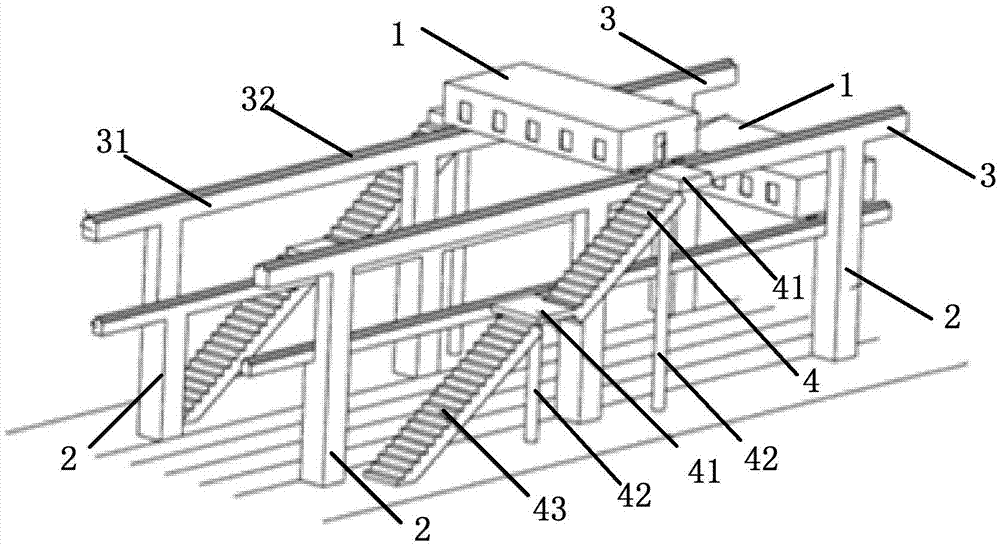

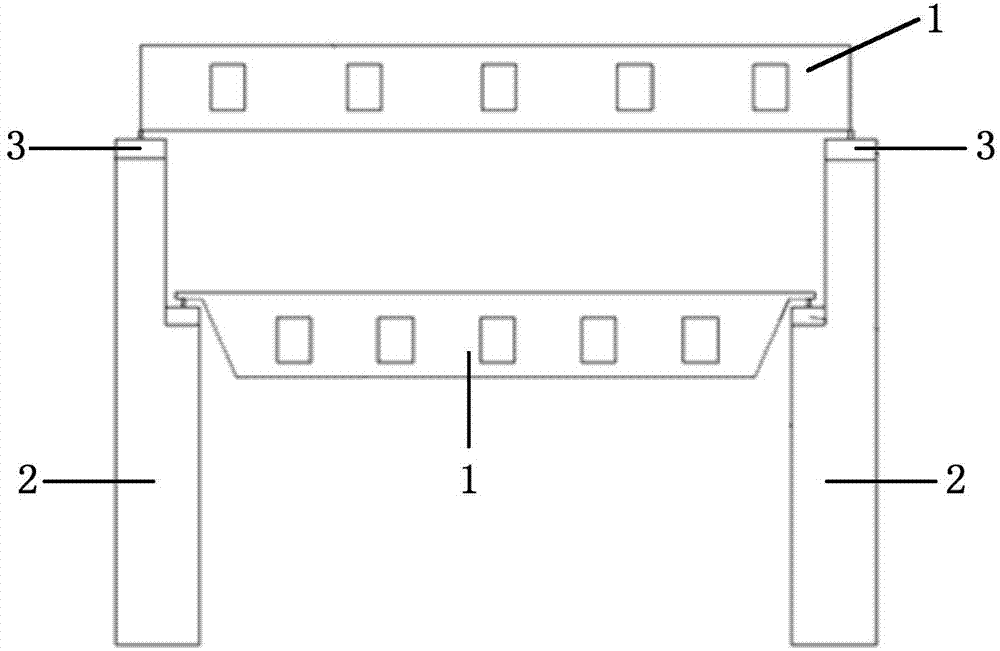

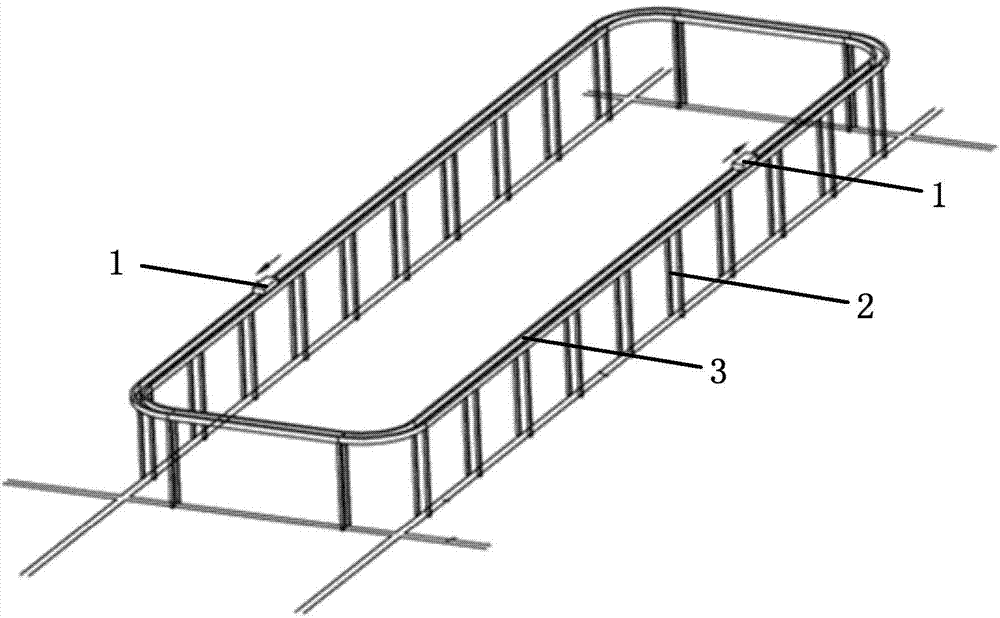

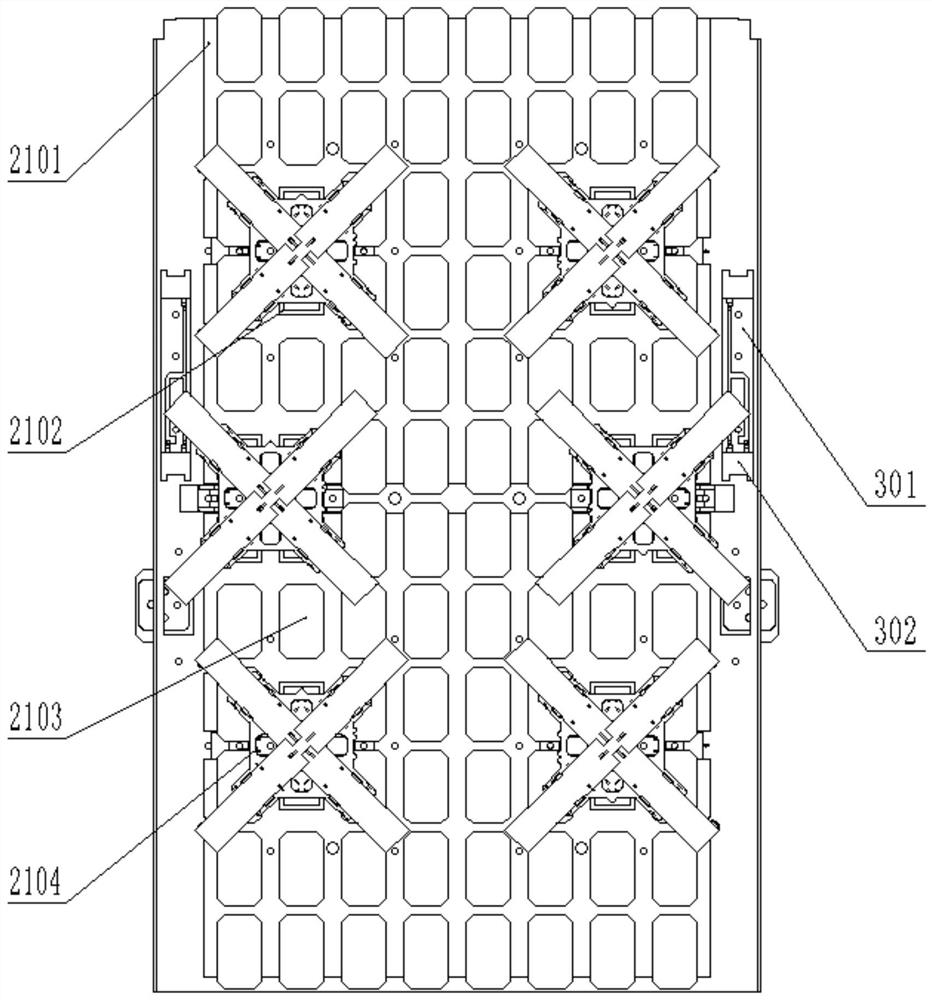

Urban overhead road-cross wide bus system

InactiveCN104711908ASave land resourcesSolve traffic jamsRailway system combinationsRailway tracksEngineeringTransit bus

The invention relates to the technical field of public transportation and provides an urban overhead road-cross wide bus system. The urban overhead road-cross wide bus system comprises a bus, bent frame columns, a track beam unit and passenger get-on and get-off platform units, wherein the track beam unit comprises two track beams arranged in parallel, the track beams are laid in the extending direction of a road, and steel rails are laid on the track beams; the bent frame columns used for supporting the track beams are arranged between the track beams and the parts, on the two sides of the road, of the ground; the passenger get-on and get-off platform units are arranged beside the track beams and are close to the track beams; wheels of the bus are matched with the steel rails, and the width of the bus is matched with that of the track beams. The urban overhead road-cross wide bus system can solve the jam problem of the bus, improve the passing efficiency of the bus and also improve the passing efficiency of common motor vehicle on the road.

Owner:DALIAN UNIV OF TECH

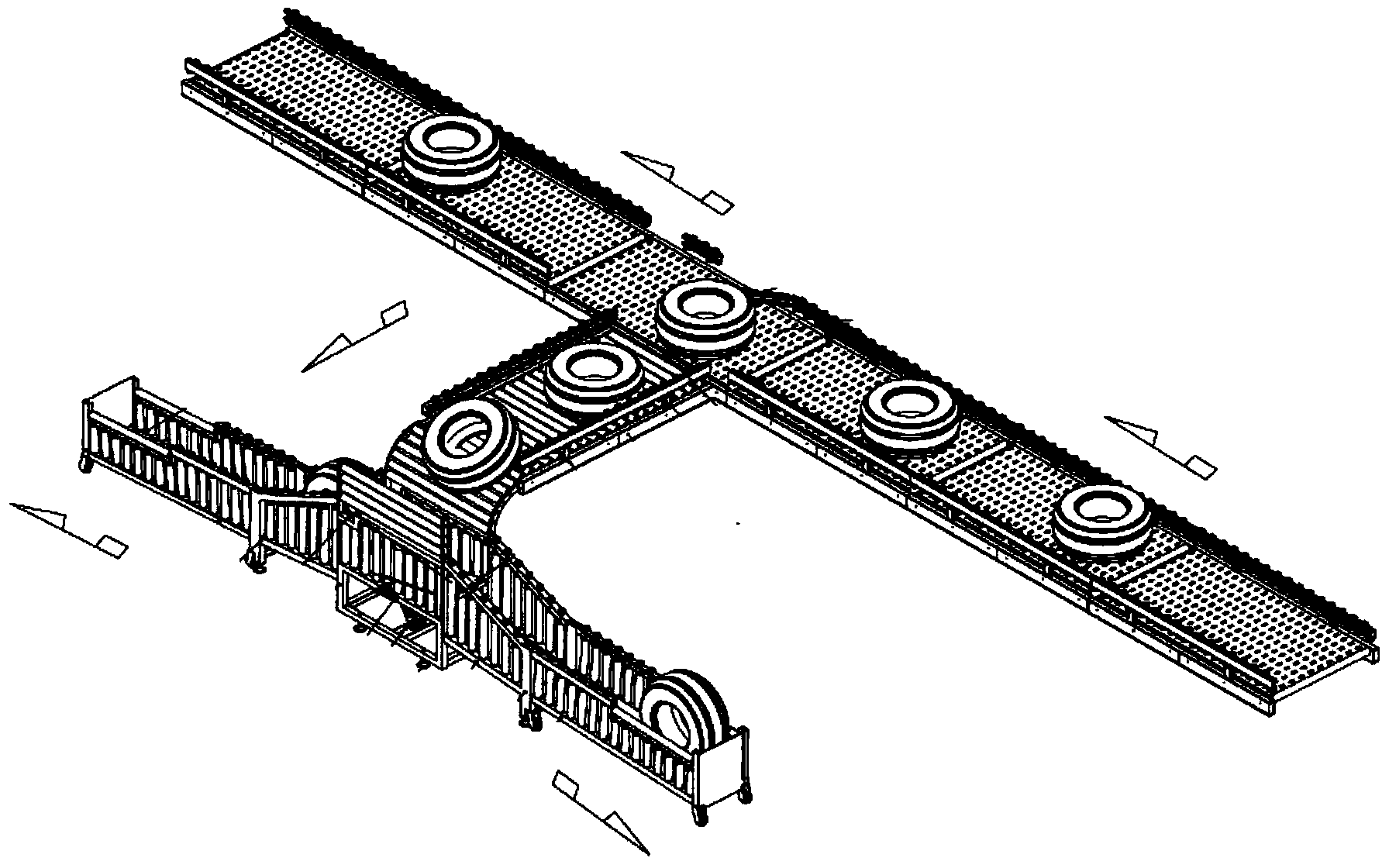

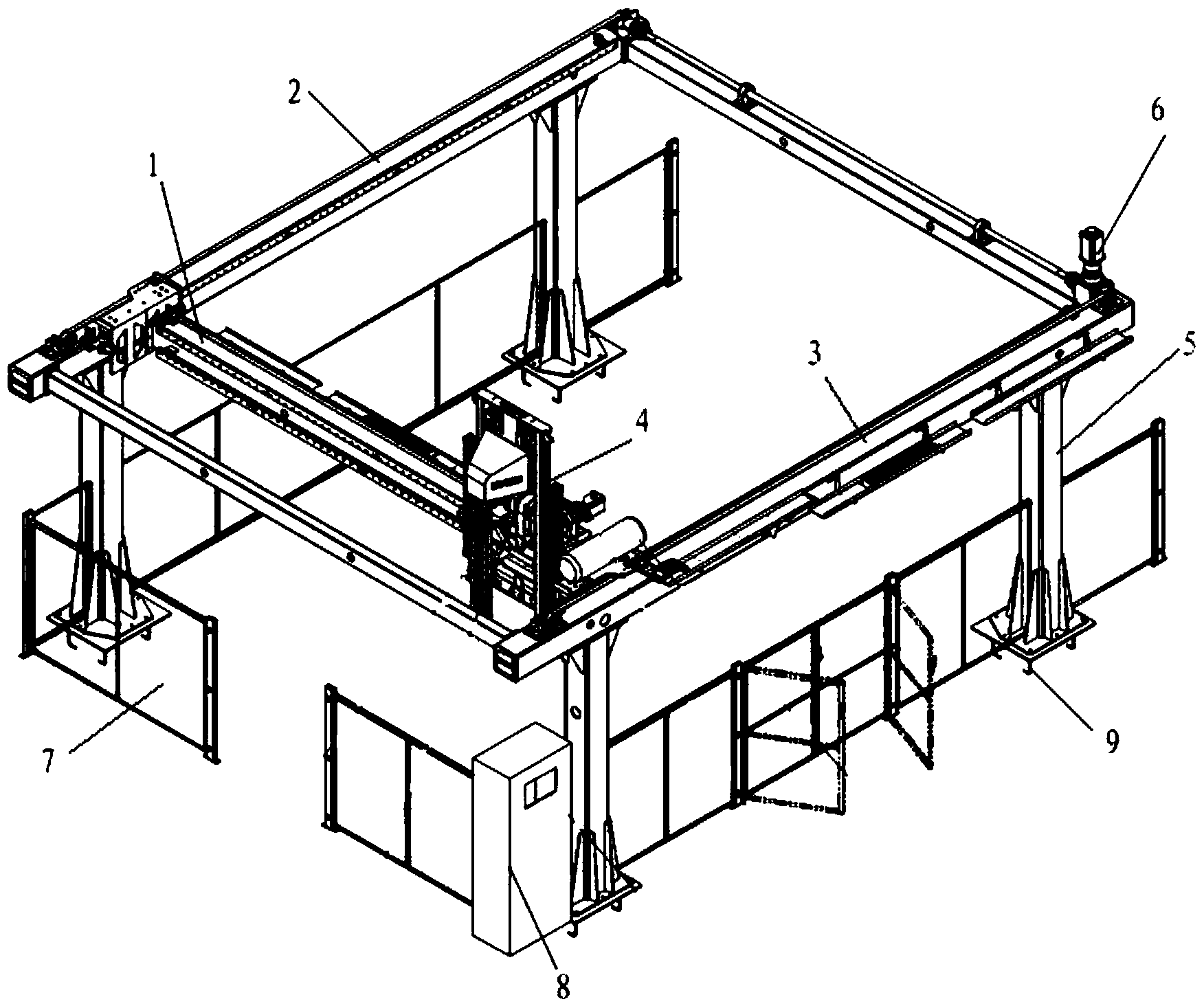

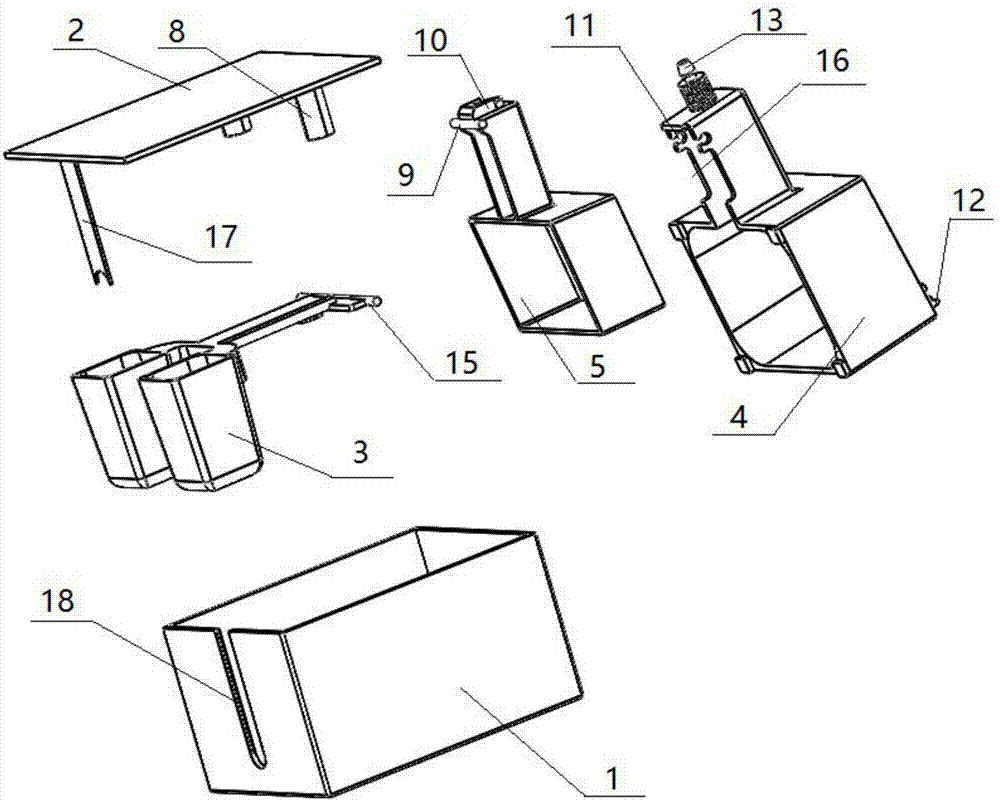

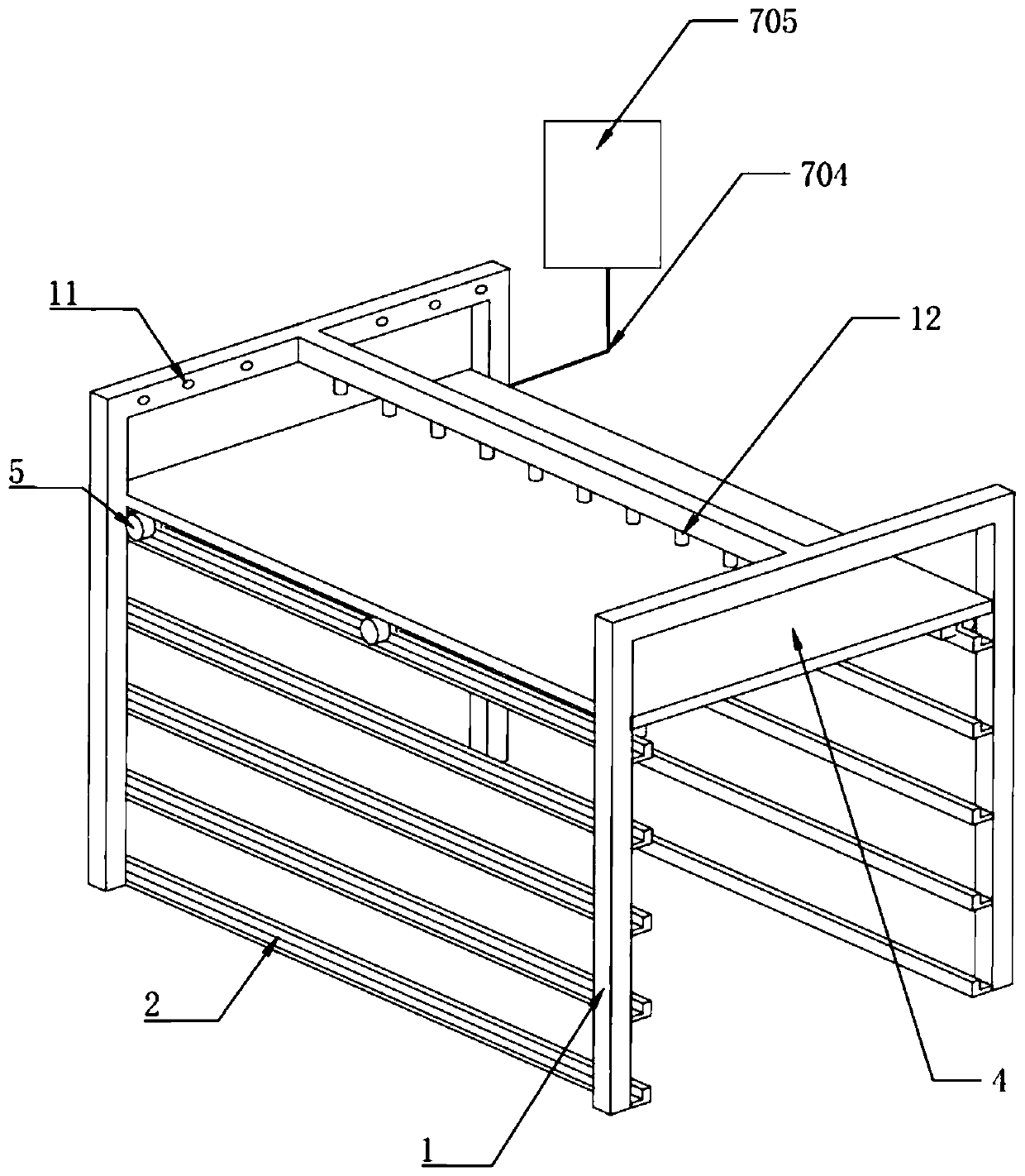

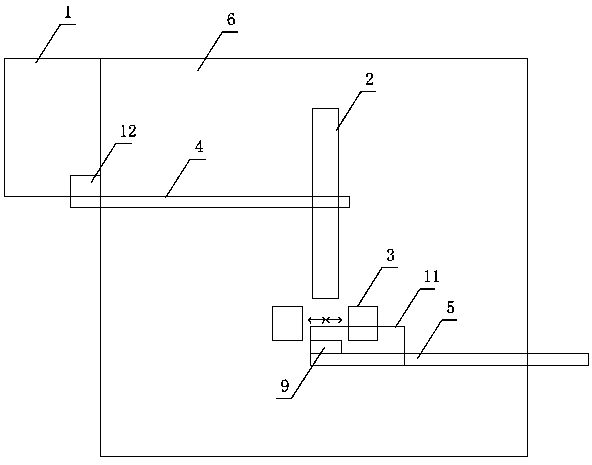

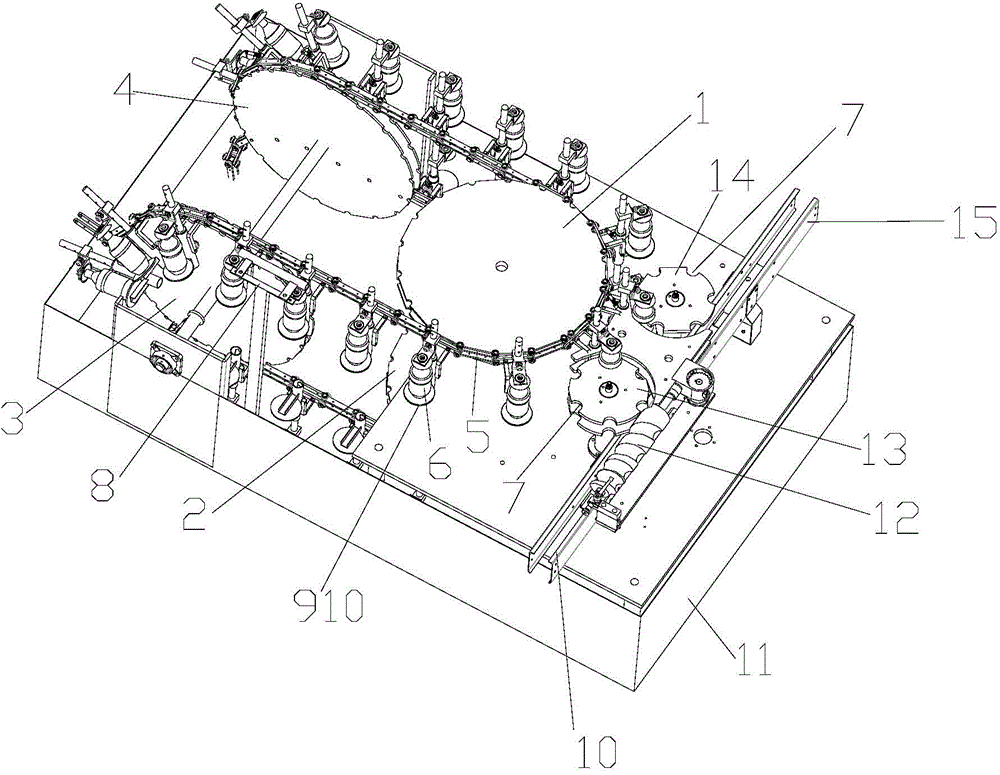

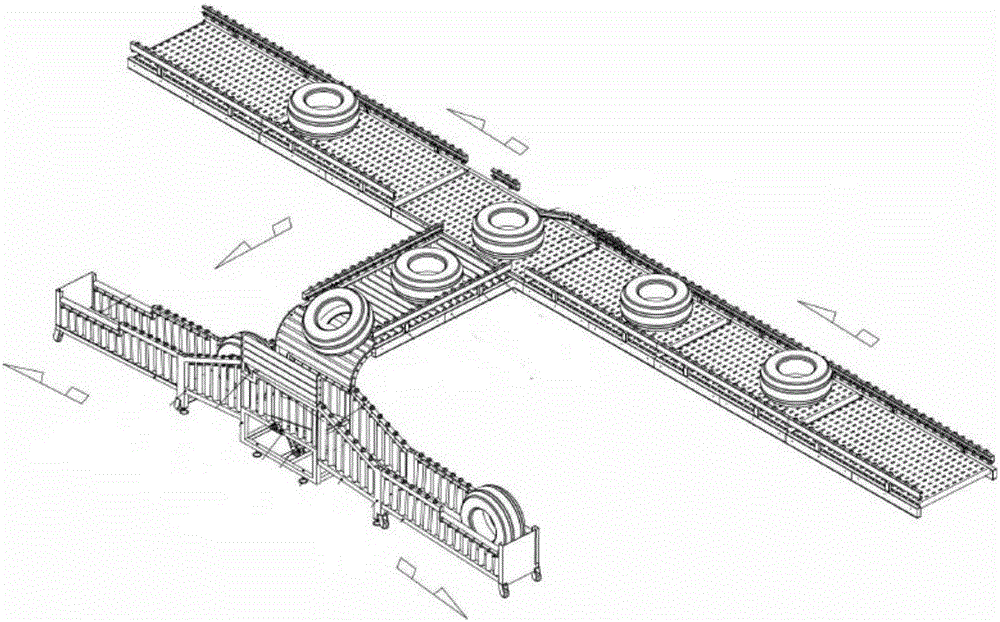

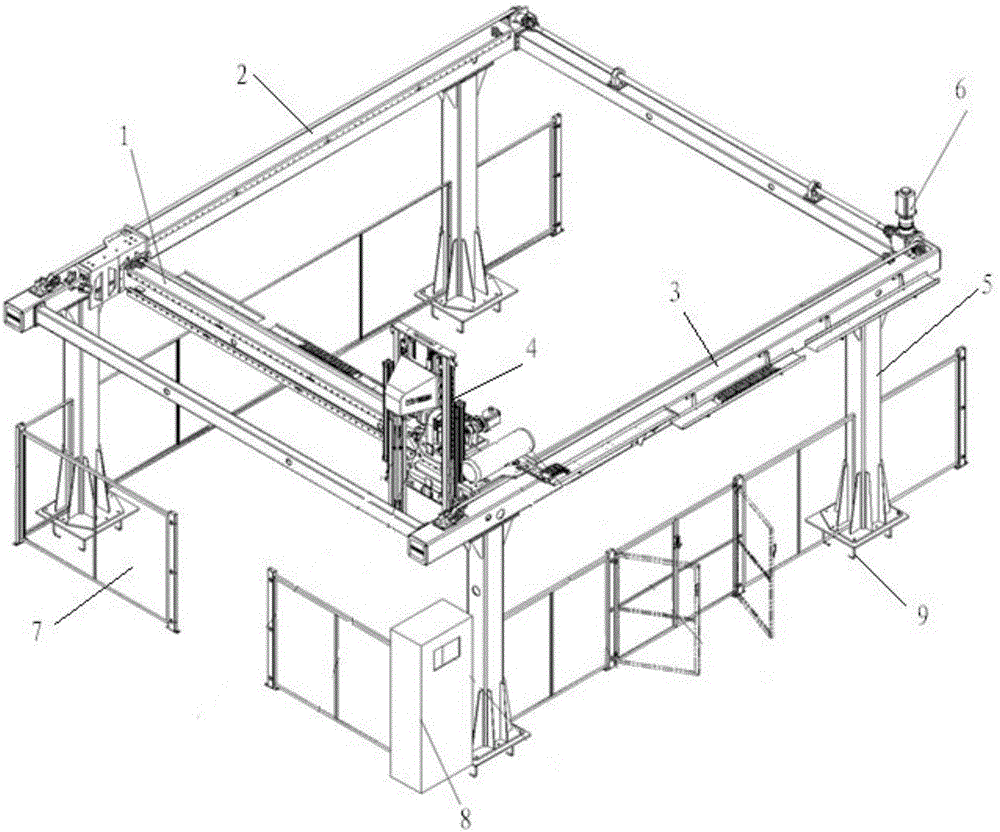

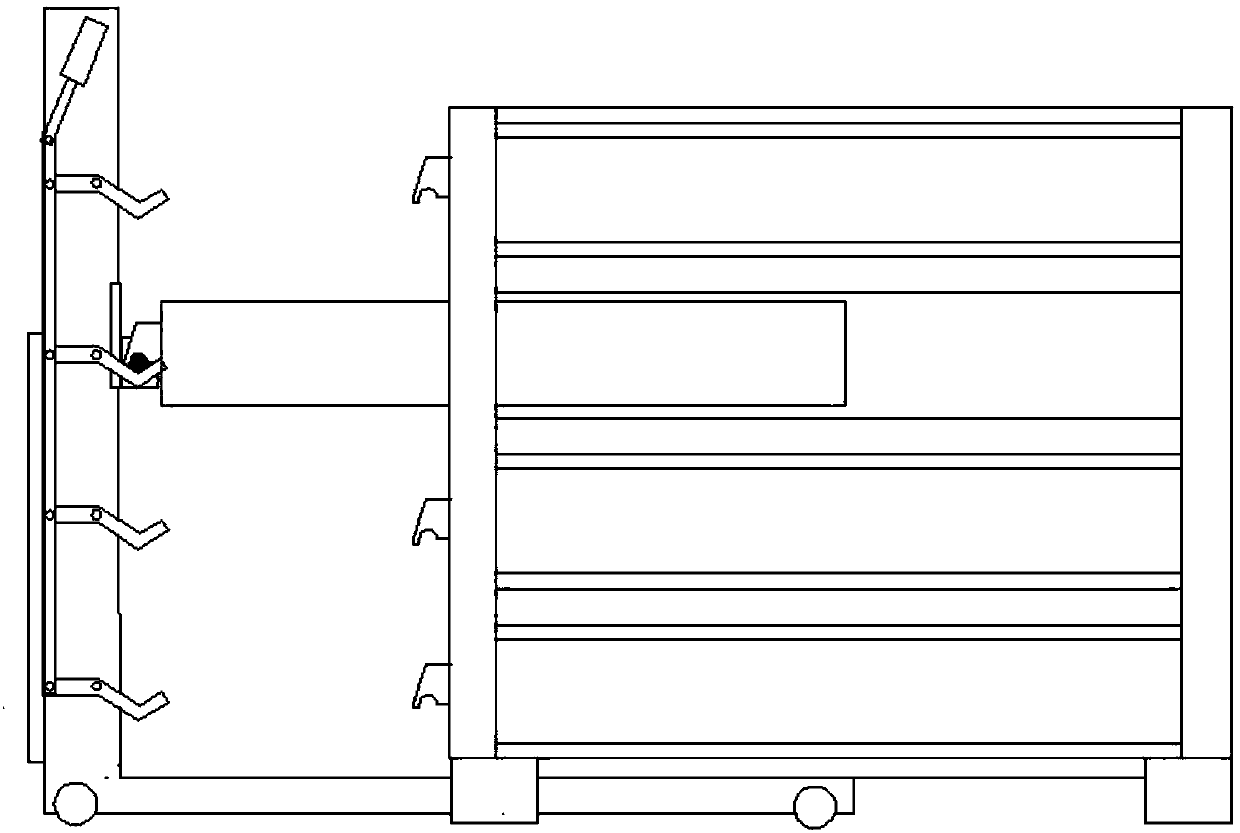

Tire carrying and destacking-stacking system and tire warehousing stacking method

ActiveCN103434850AAvoid increased labor costsEven by forceStacking articlesDe-stacking articlesManipulatorElectrical and Electronics engineering

The invention discloses a tire carrying and destacking-stacking system, which comprises a support mechanism, a carrying mechanism and a power device, wherein the support mechanism comprises a first longitudinal beam and a second longitudinal beam which are arranged in parallel, and a support vertical column for supporting the first longitudinal beam and the second longitudinal beam; the carrying mechanism comprises a movable transverse beam and a carrying manipulator; the movable transverse beam stretches across the first longitudinal beam the second longitudinal beam, and is in slide fit with the first longitudinal beam and the second longitudinal beam along the longitudinal directions of the two longitudinal beams; the carrying manipulator is arranged on the movable transverse beam, and is in slide fit with the movable transverse beam along a transverse direction; the carrying manipulator comprises a grasping part used for grasping a tire, and a lifting assembly for controlling the grasping part to move vertically; the power device comprises a longitudinal power device used for driving the movable transverse beam to move along a longitudinal direction, and a transverse power device used for driving the carrying manipulator to move along a transverse direction. According to the tire carrying and destacking-stacking system, full automation of tire carrying and destacking-stacking is realized.

Owner:青岛科捷机器人有限公司

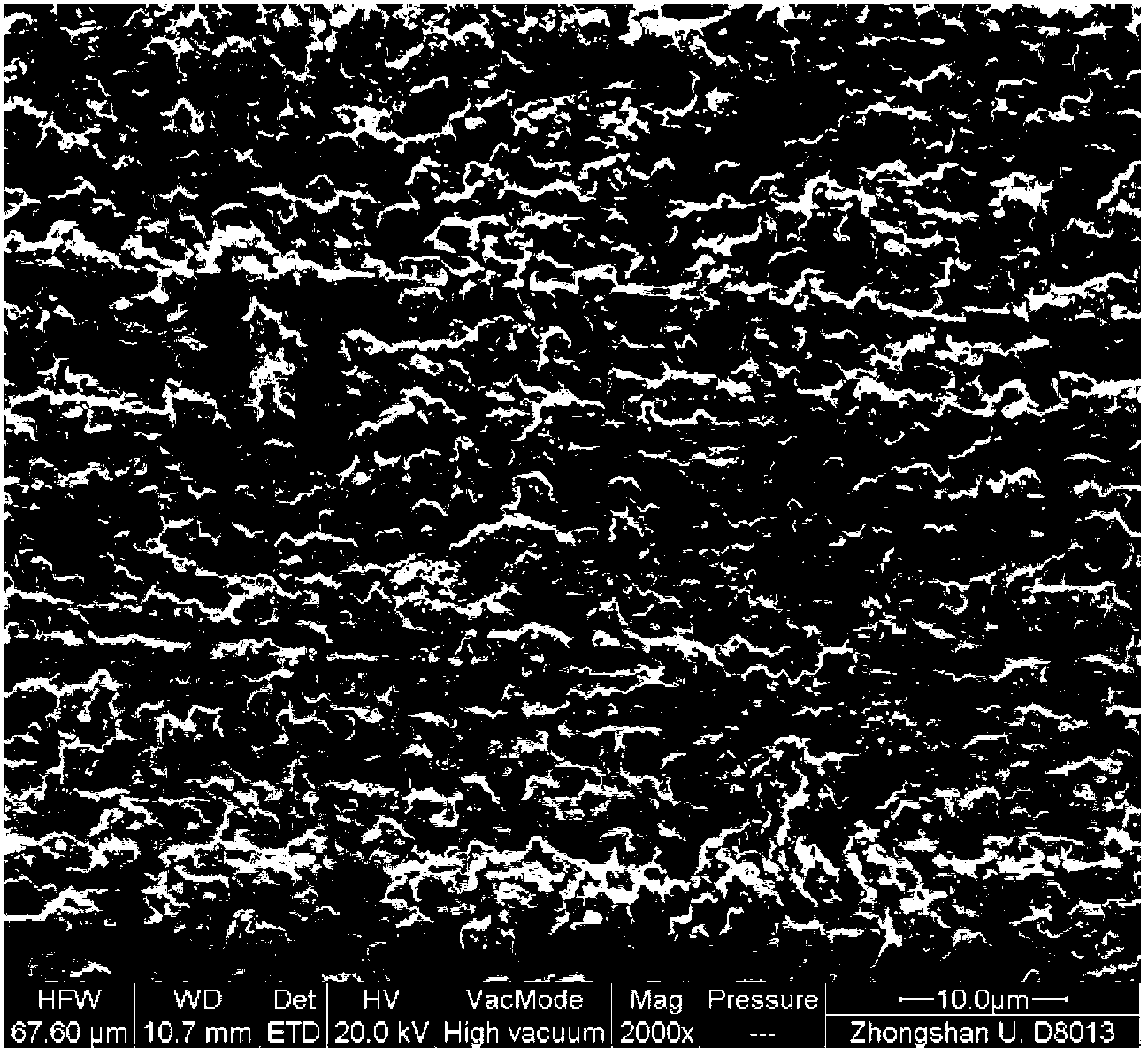

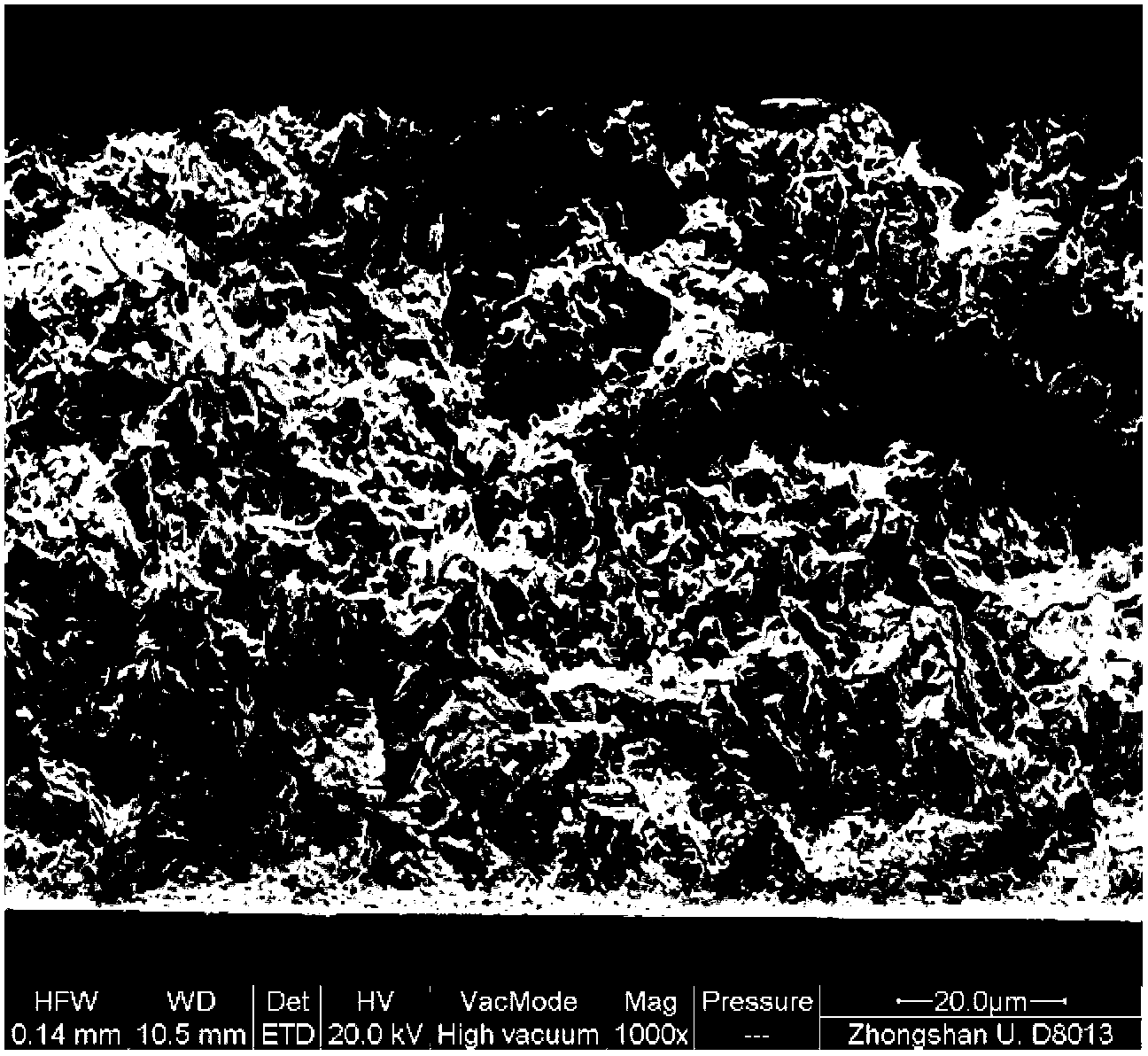

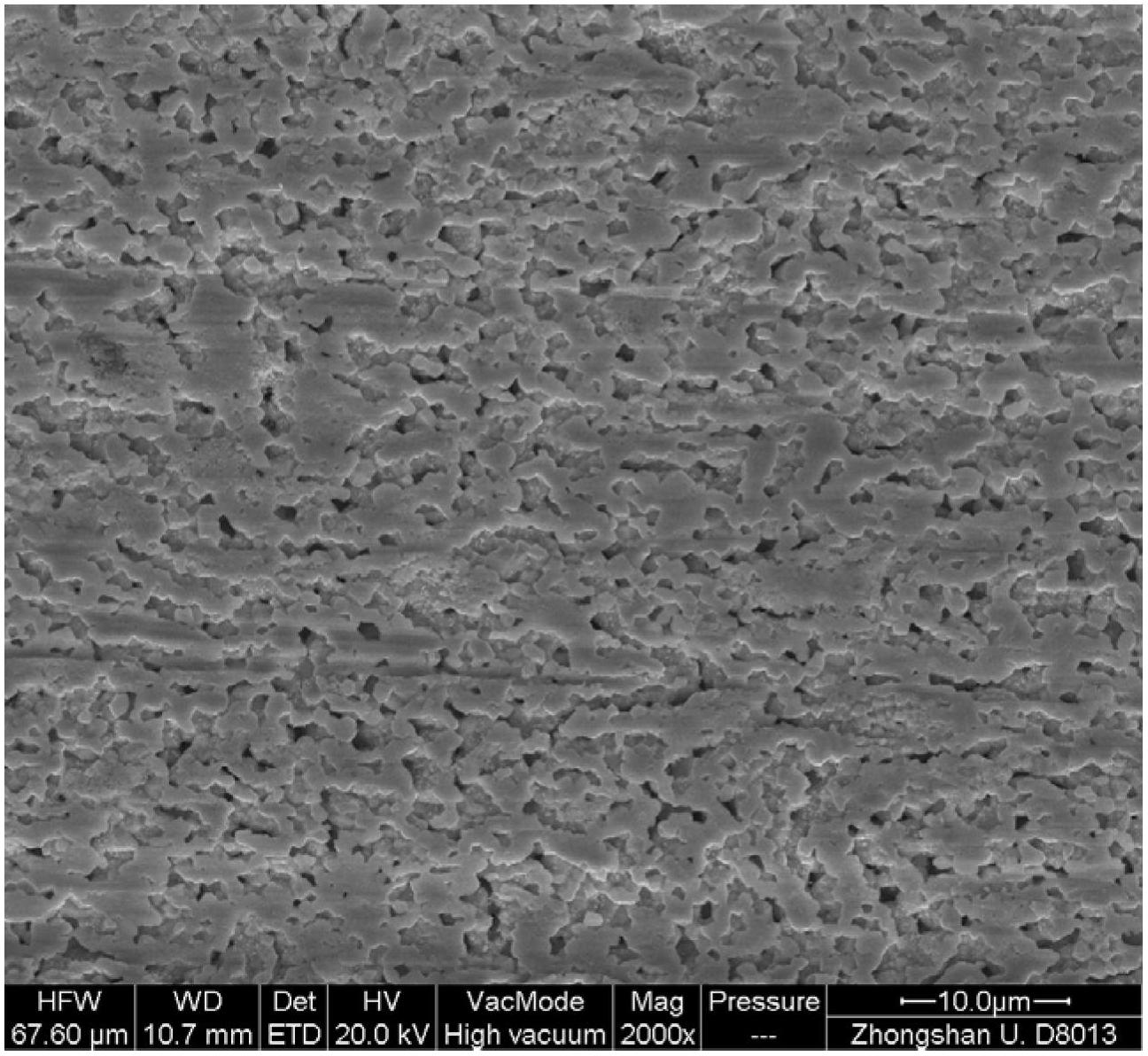

Micro-nano porous bismuth electrode and preparation method thereof

InactiveCN102706937AReduce manufacturing costSimple processMaterial electrochemical variablesIonAnodic oxidation

The invention discloses a micro-nano porous bismuth electrode and a preparation method thereof. The preparation method for the micro-nano porous bismuth electrode comprises the following steps: preparing a tin bismuth alloy, wherein a mass ratio of tin to bismuth in the tin bismuth alloy is 1:(0.5-6); processing appearance of the tin bismuth alloy, thereby obtaining a tin bismuth alloy electrode; performing alloy tin-melting treatment on the tin bismuth alloy electrode according to an electrochemical method, and arranging a tin-melting potential between corrosion potentials of metal tin and bismuth, thereby obtaining the micro-nano porous bismuth electrode; and if necessary, performing anodic oxidation treatment on the micro-nano porous bismuth electrode, thereby obtaining the micro-nano porous bismuth electrode with suitable pores and size. The preparation method provided by the invention has the advantages of simple technology, environmental protection and zero pollution; the production cost of the micro-nano porous bismuth electrode is low; and the obtained micro-nano porous bismuth electrode has the advantages of strong adjustability of microstructure, flexible and controllable macroscopic shape and size, big specific surface area, high detection sensitivity and application to the detection for trace heavy metal ions and trace organic matters in liquid.

Owner:SUN YAT SEN UNIV

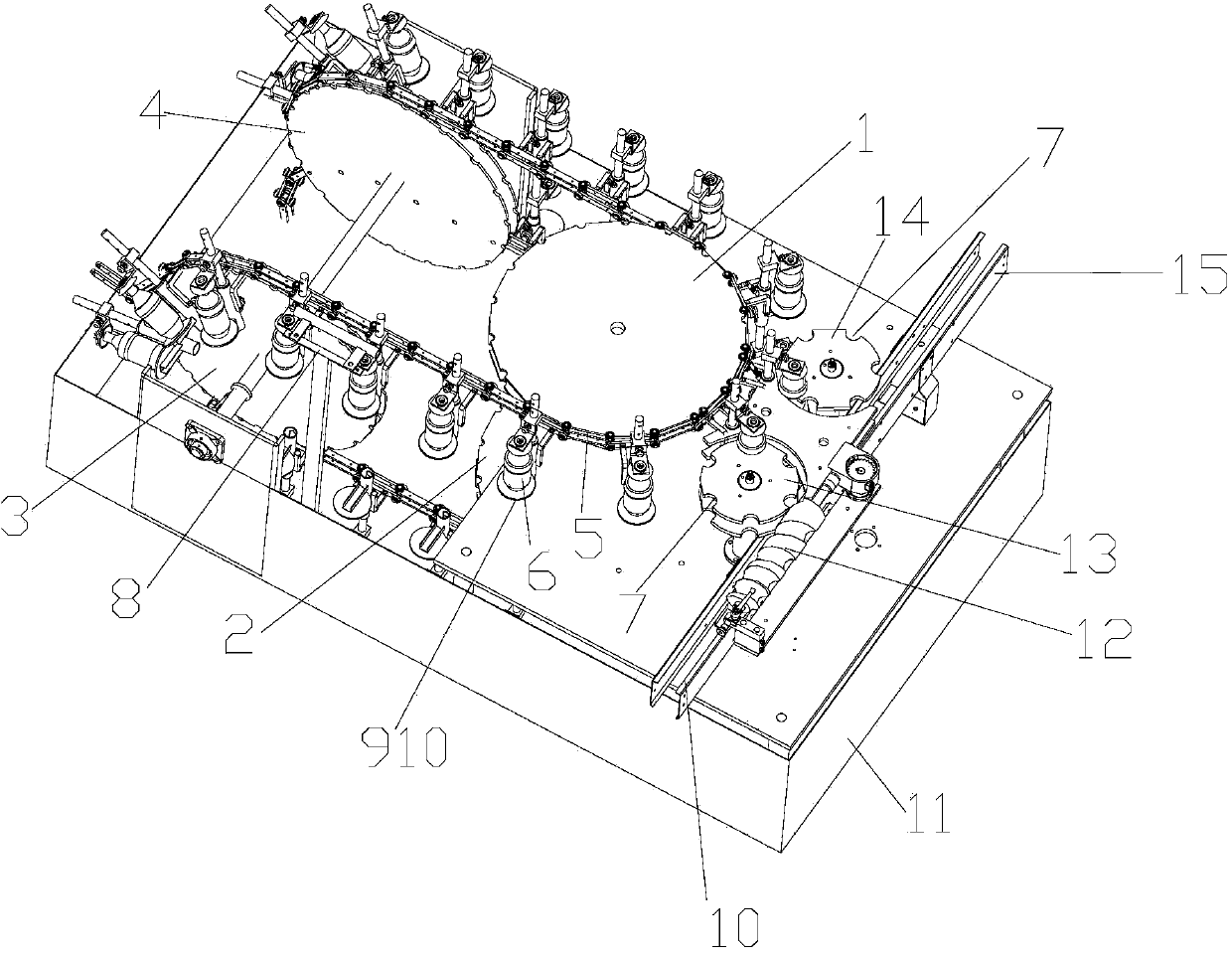

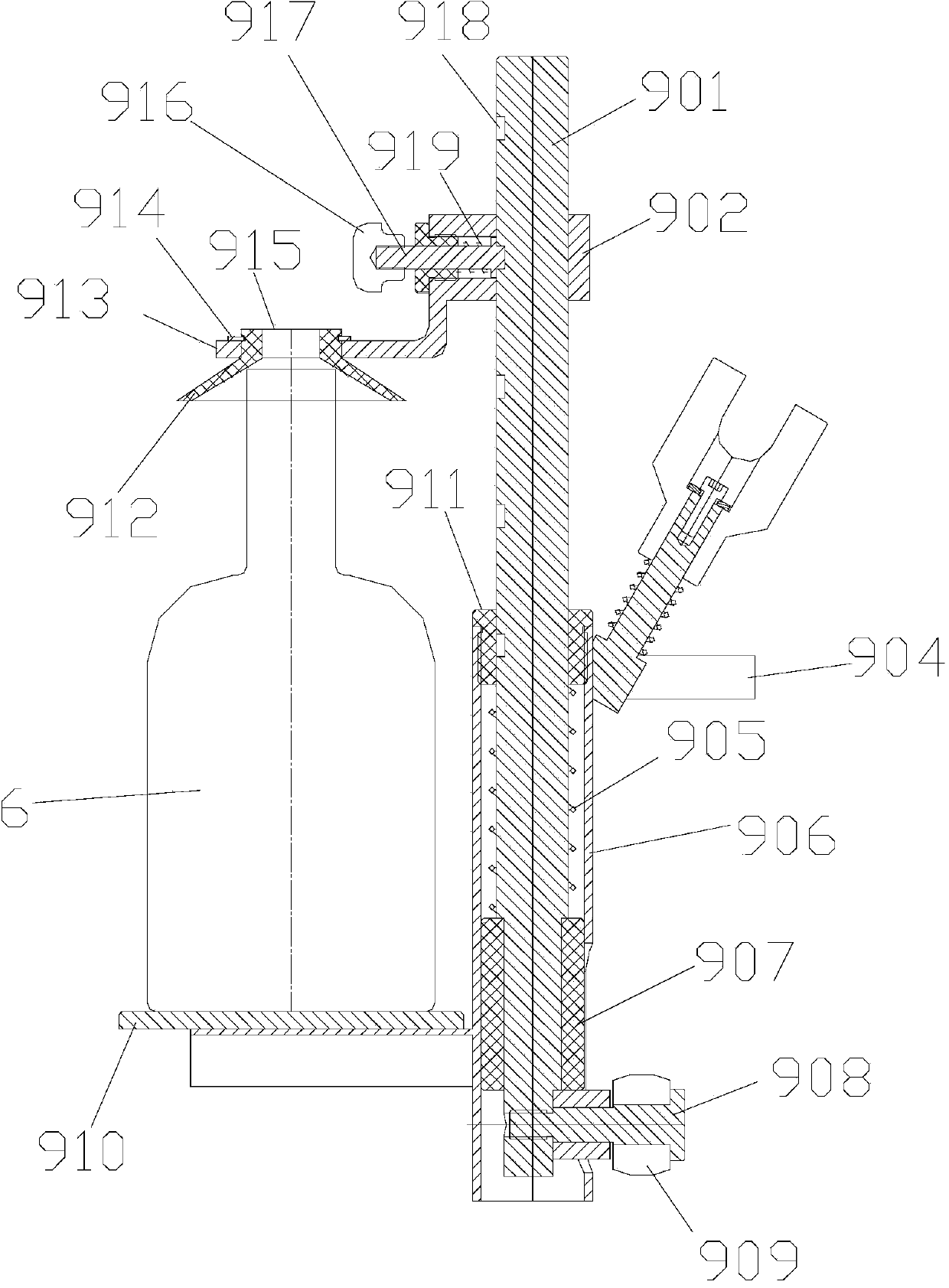

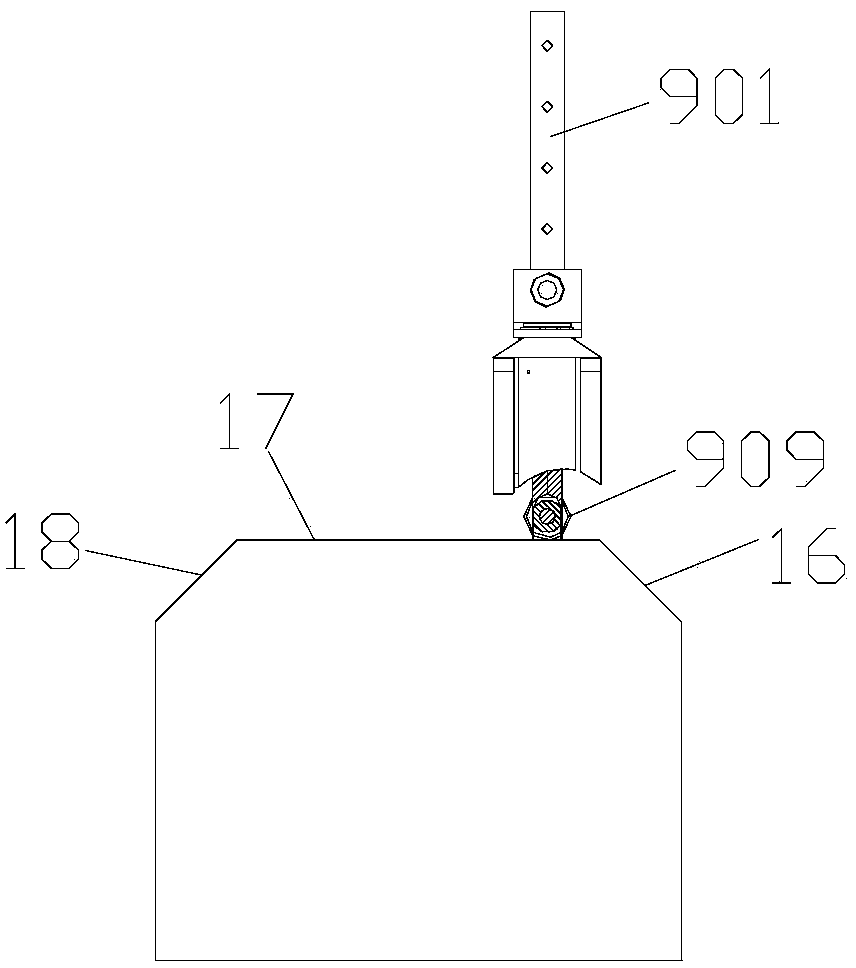

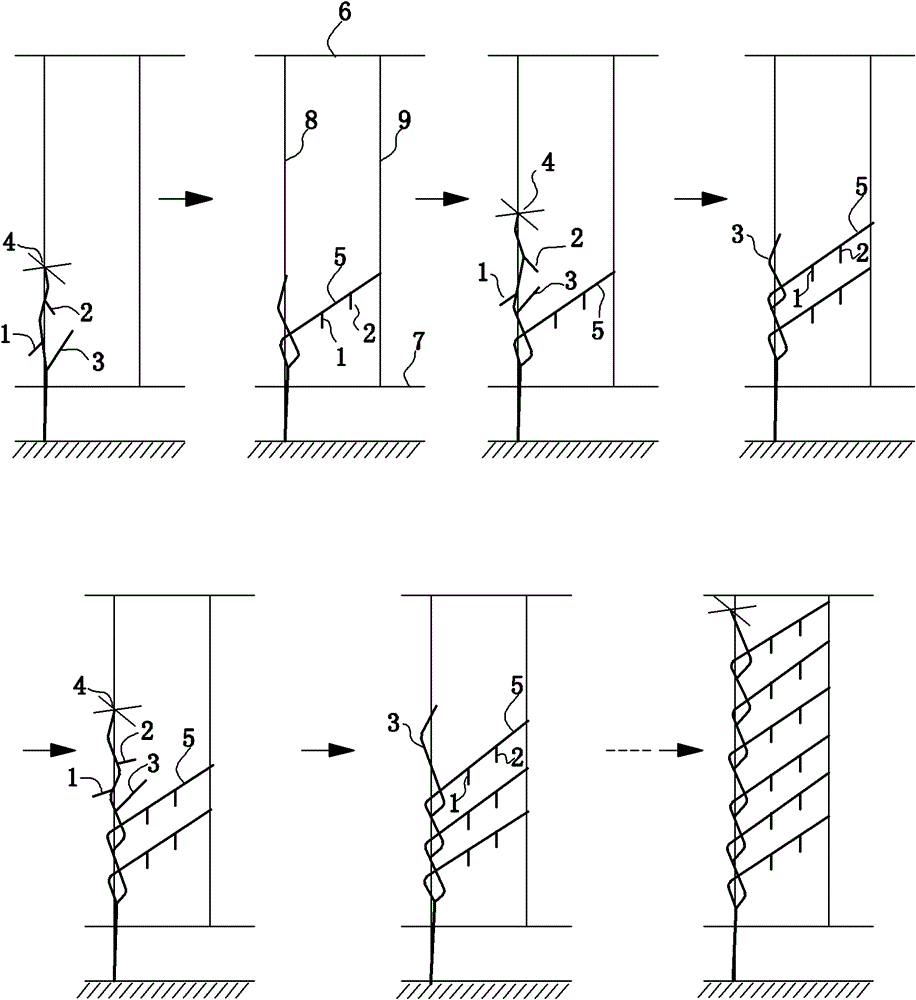

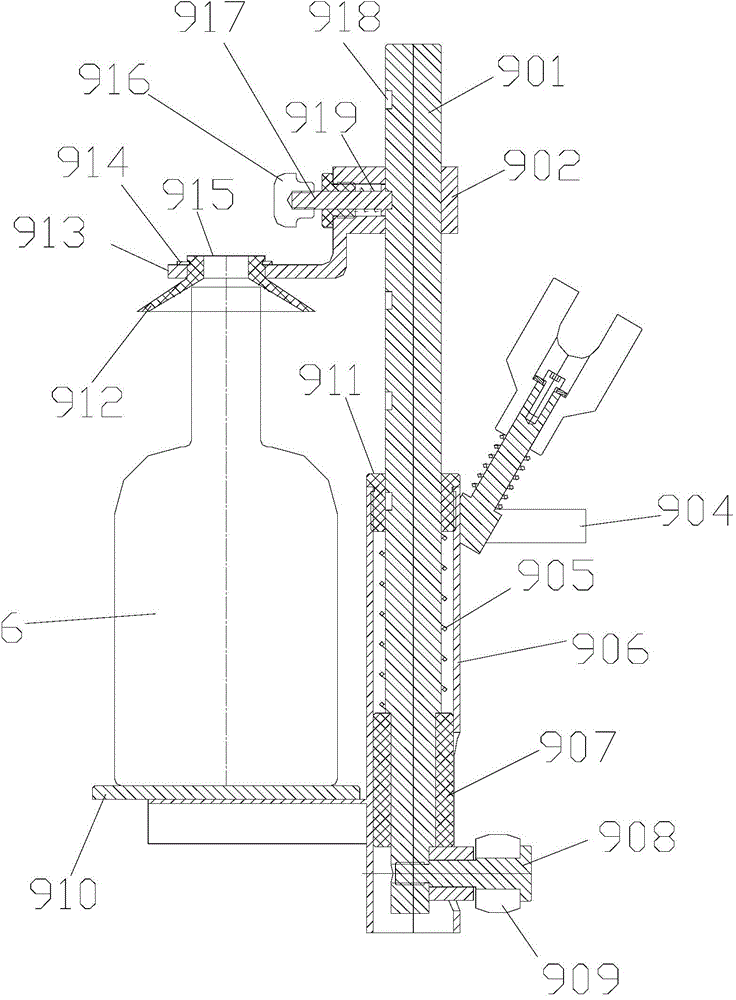

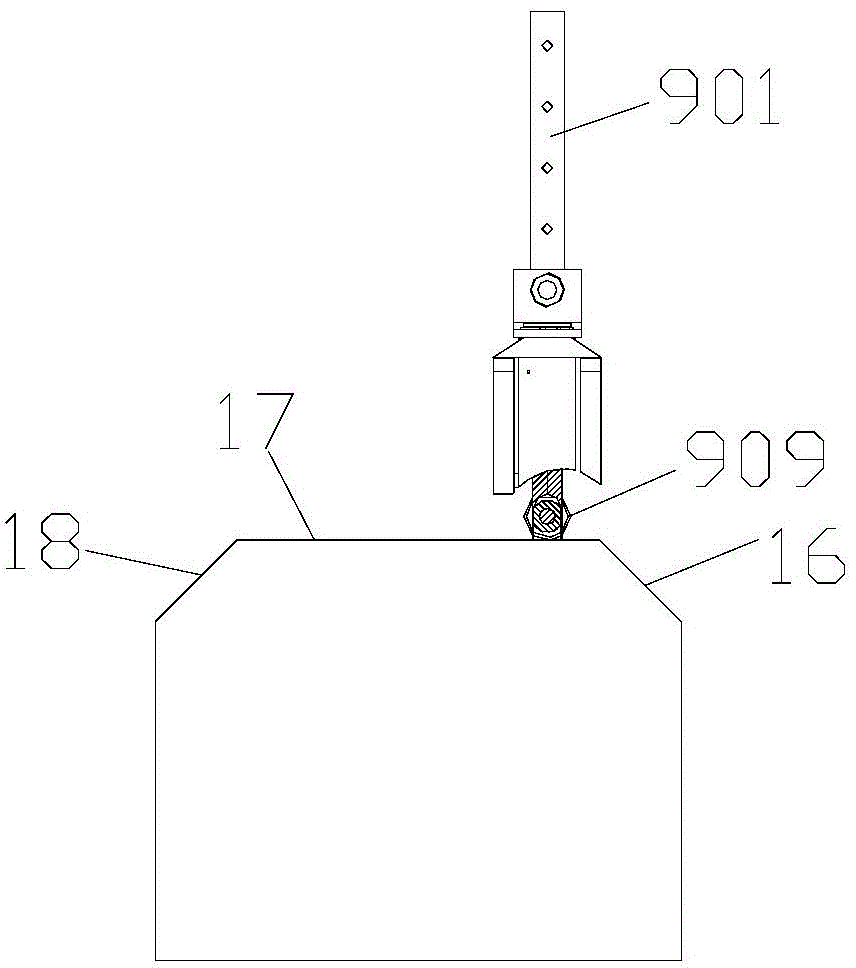

Stereoscopic bottle washing machine and bottle washing method

The invention discloses a stereoscopic bottle washing machine and a bottle washing method, which have a good bottle washing effect and occupy a small area. The bottle washing machine comprises a first chain wheel and a second chain wheel which are horizontally arranged; the second chain wheel is positioned below the first chain wheel; one group of chain wheels also comprises a third chain wheel and a fourth chain wheel which are vertically arranged; a bottle feeding mechanism and a bottle discharging mechanism are respectively arranged outside the first chain wheel; a chain between the first chain wheel and the third chain wheel is a bottle body soaking section; a rack corresponding to the bottle body soaking section is provided with a first water spraying mechanism for spraying water into a bottle body; a chain between the third chain wheel and the second chain wheel is a bottle body water pouring section; the rack corresponding to the second chain wheel is provided with a second water spraying mechanism for spraying water to the outer wall of the bottle body and spraying water into the bottle body. The method mainly applies the bottle washing machine to wash the bottle body. The bottle washing machine disclosed by the invention has a simple structure, is reasonably laid out and saves the space.

Owner:LUZHOU HUIJIANG MACHINERY MFG

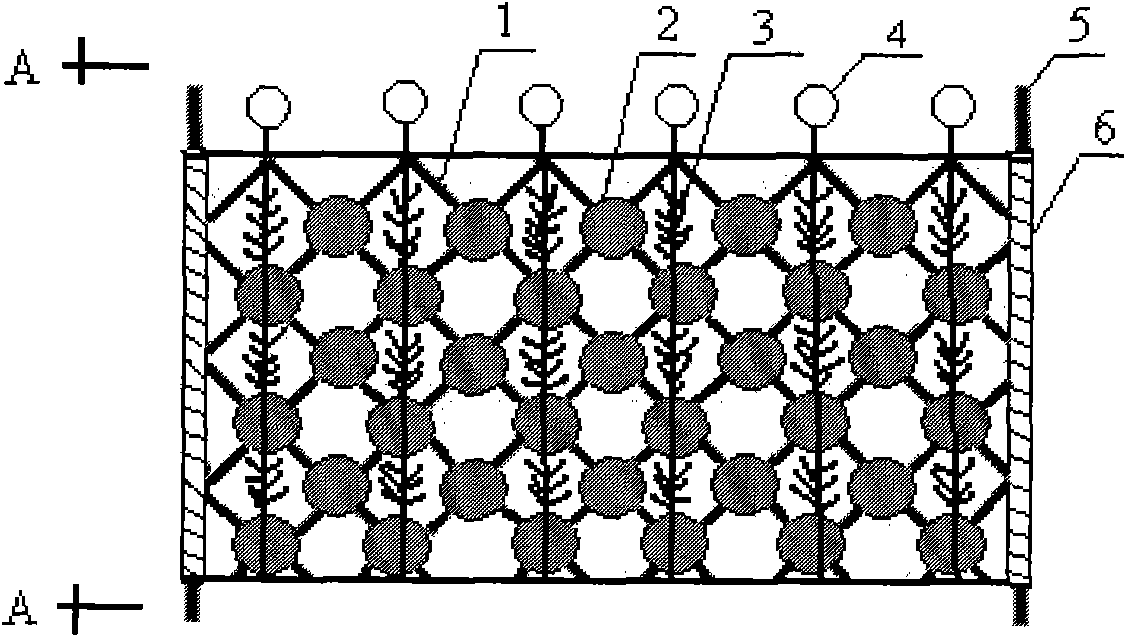

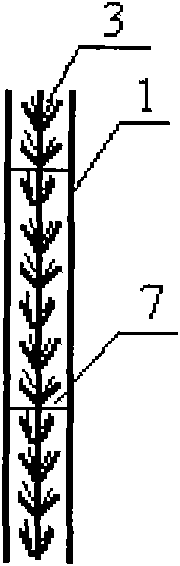

Ecological net packing device

InactiveCN101863558AStrong adsorption and interception abilityImprove removal efficiencyBiological water/sewage treatmentWater flowWater quality

The invention relates to an ecological net packing device, which consists of rope nets, combined packing units, floating balls, sleeves, fixing rods and submerged plants. The combined packing units are fixed on knots of the rope nets; a sandwich structural mode is adopted, and the matched submerged plants are sandwiched and fixed between two rope nets; the upper ends of the rope nets are connected with the floating balls, and two sides of the rope nets are fixedly connected with the sleeves through side fixing lines; and in the using process, fixing rods are inserted into the sleeves on the two sides, and the two fixing rods are respectively inserted into water body riverbed or lakebed so as to fix the ecological net packing in water. The ecological net packing device has the characteristics of good water quality purifying effect, simple structure, convenient processing and transportation, no blockage or caking, simple installation, convenient management and maintenance, strong current impact resistance and the like, and can be used for in-situ purification of natural water bodies such as riverways and lakes and artificial water bodies.

Owner:TONGJI UNIV

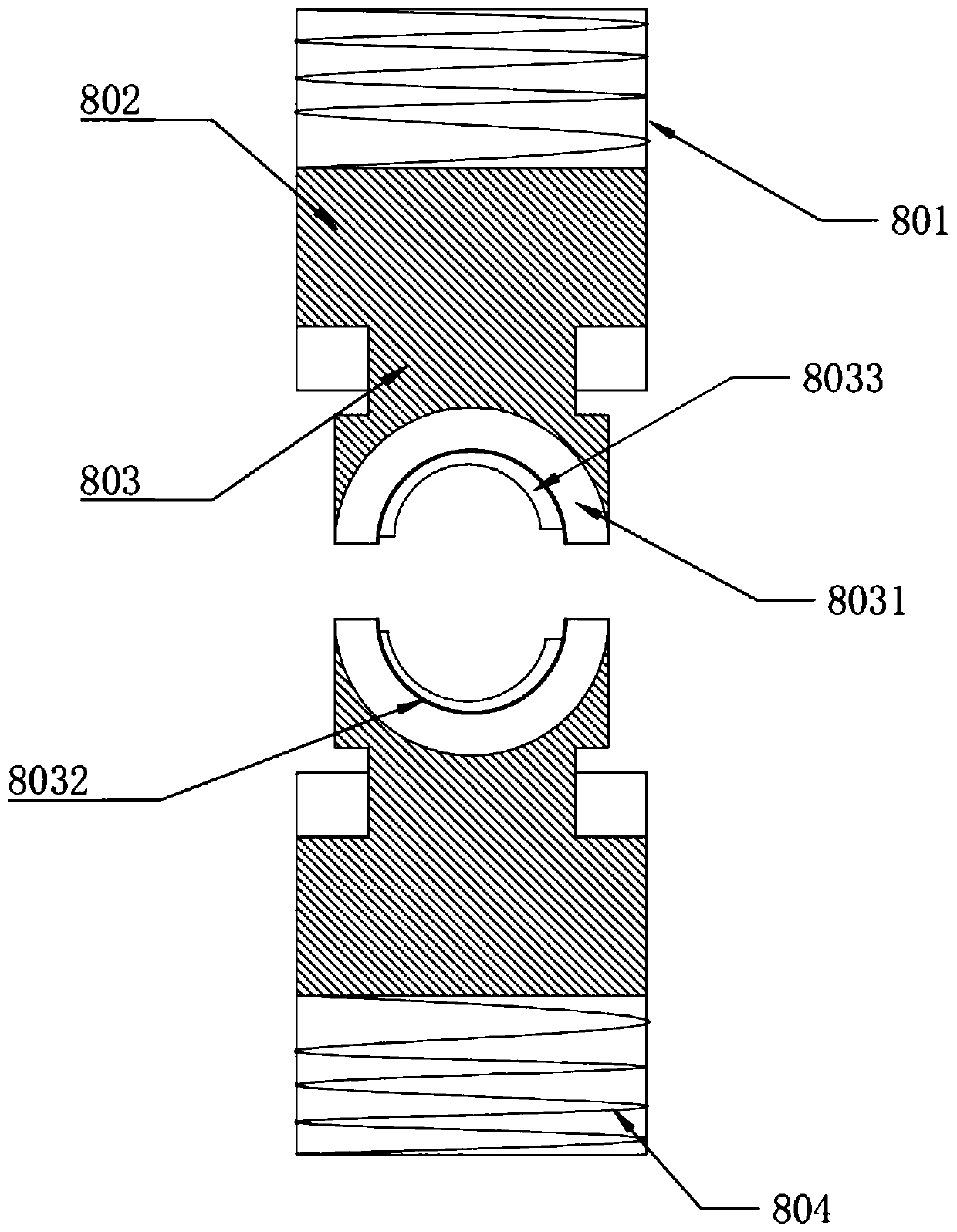

Multi-functional planting system

InactiveCN107343471AFirmly connectedEasy to disassemble and overhaulAgriculture gas emission reductionCultivating equipmentsWater sourceAgricultural engineering

The invention relates to the technical field of agricultural planting equipment, in particular to a multi-functional planting system which is applicable to the fields of vegetable soilless culture, vegetable hydroponics, plant factories, barren hill afforestation, desertification control and roof greening, and a highly controlled valve body can be realized without the aid of external power. The system comprises a protective shell and an automatic liquid level height control mechanism, wherein the automatic liquid level height control mechanism comprises a sealing float, a water storage chamber and a water stopping float and the water storage chamber is provided with a water source connector. Through the water source connector, convenient connection with a water source is realized, and the sealing float is additionally arranged, so that effective protection of the automatic liquid level height control mechanism is realized while disassembly, assembly and maintenance are facilitated. Due to an independent packaging mode, the system can be used for any planting containers, the drop and rise of the water level in the containers can be realized by just fixing the system of the invention in the planting containers without any changes to the planting containers.

Owner:甘肃绿野上品生态农业科技发展有限公司

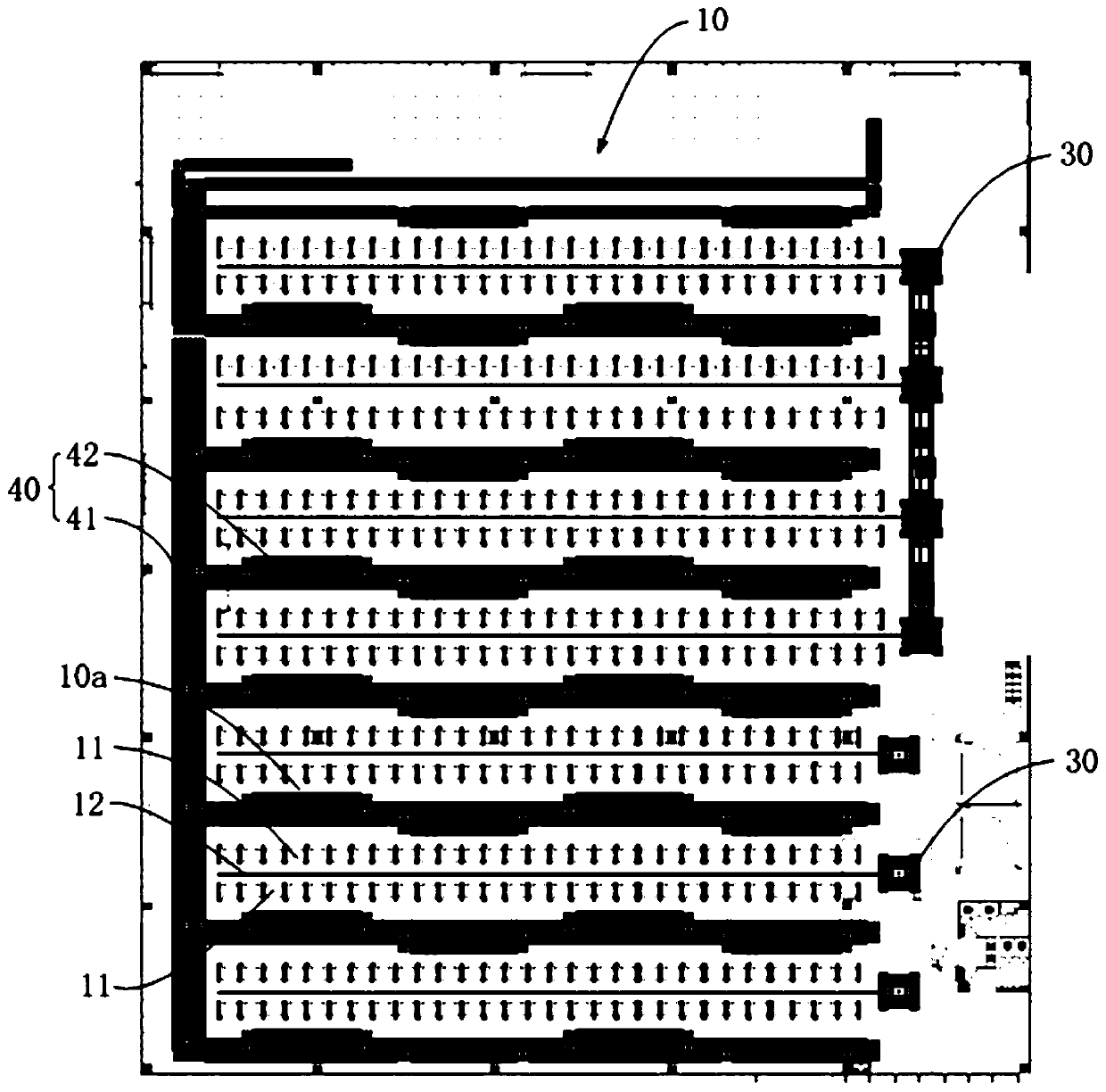

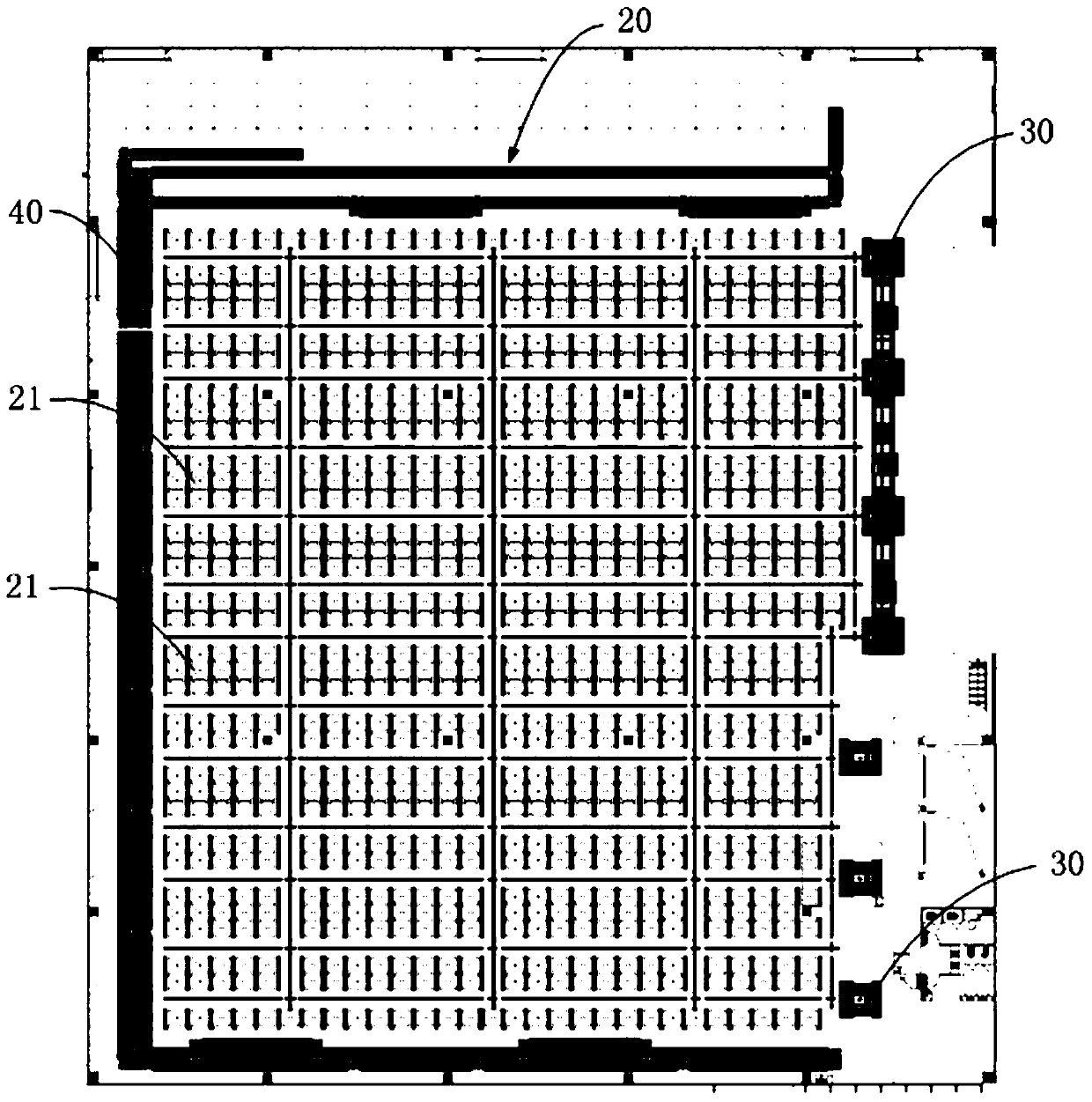

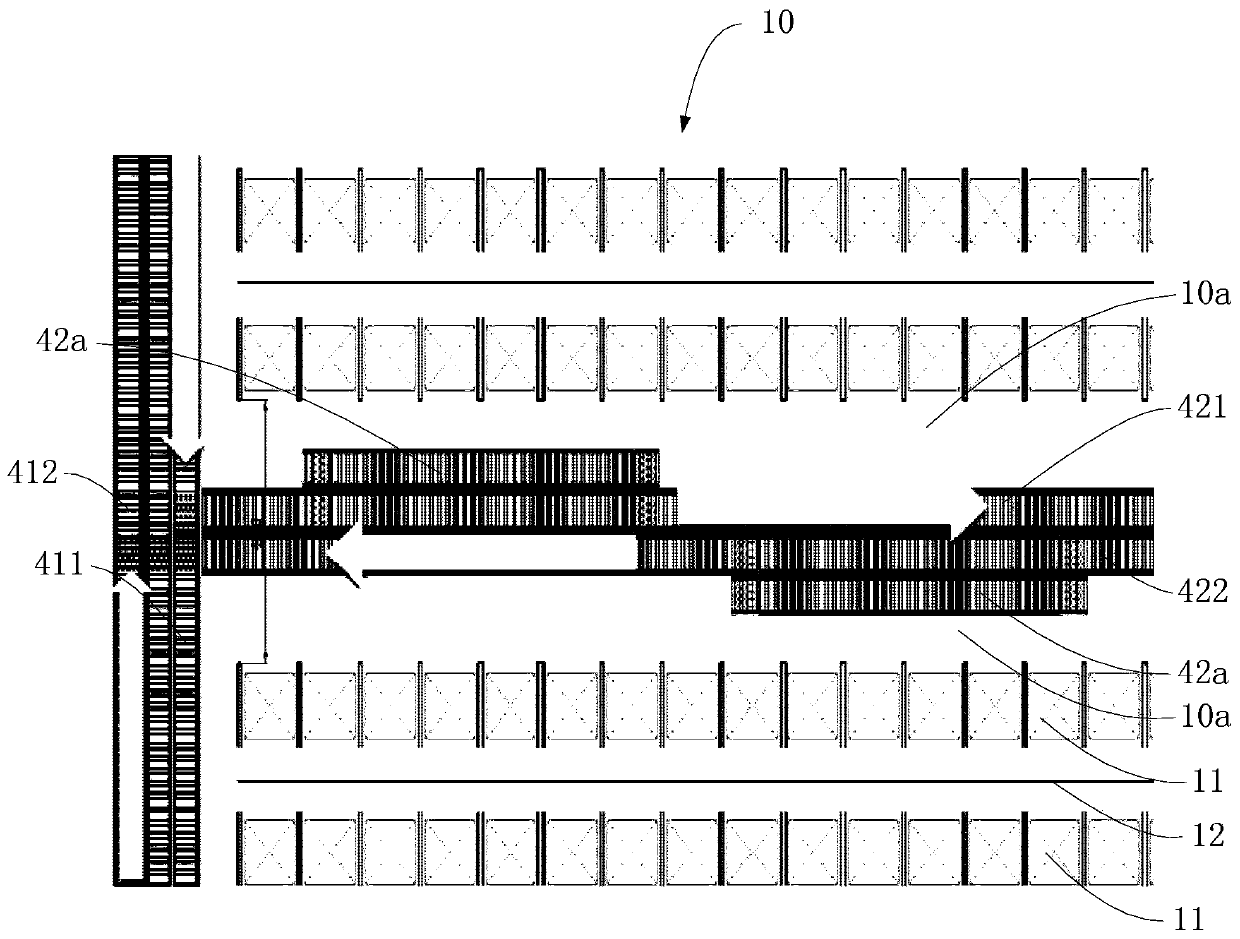

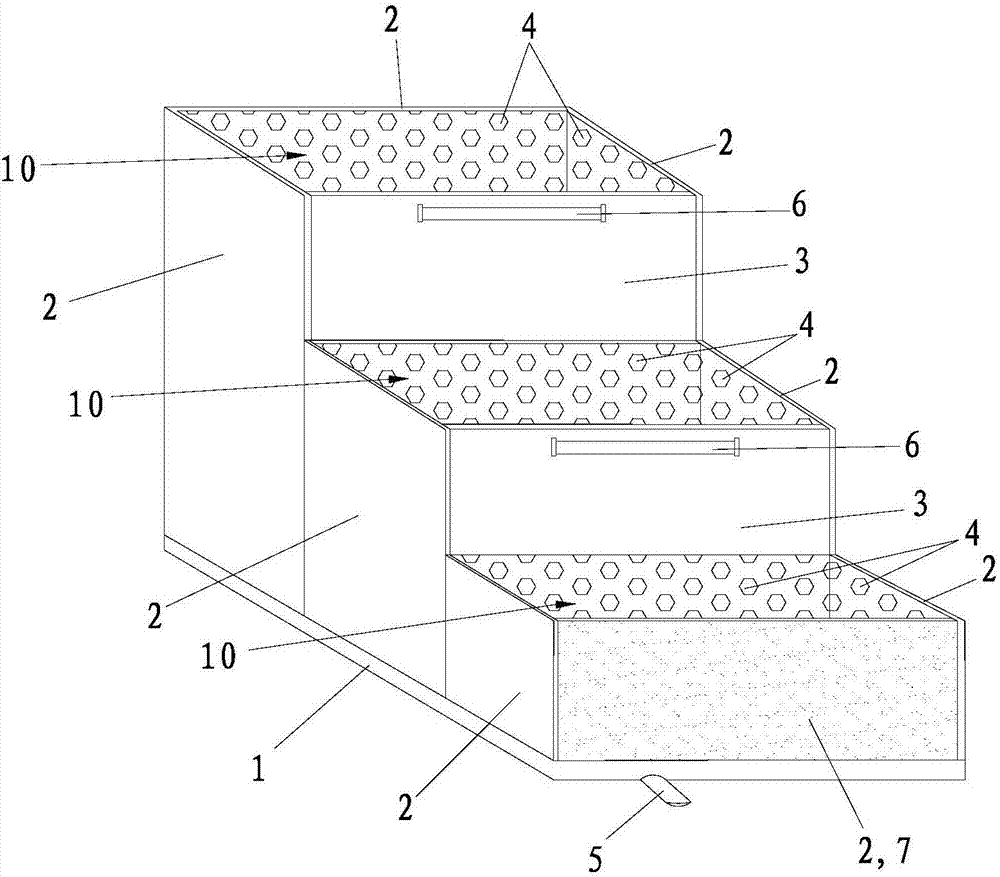

Warehouse, sorting system with warehouse, sorting method and sorting device

PendingCN110255029AMake full use of the three-dimensional spaceImprove space utilizationConveyorsStorage devicesAutomationTransport engineering

The embodiment of the invention discloses a warehouse, a sorting system with the warehouse, a sorting method and a sorting device. The warehouse comprises storage layers, goods sorting layers, a lifting device and a goods sorting conveying line; the storage layers and the goods sorting layers are arranged at intervals from top to bottom; each goods sorting layer comprises a plurality of goods sorting areas; the lifting device is used for vertically moving between the storage layers and the goods sorting layers; and the goods sorting conveying line passes through the plurality of goods sorting areas. According to the warehouse of the embodiment of the invention, by means of the storage layers and the goods sorting layers which are distributed ay intervals in the vertical direction, the function dividing of storage and sorting of goods in the height direction can be achieved, the three-dimension space of the warehouse is fully utilized, on the one hand, the efficiency of goods sorting operation can be improved, and on the other hand, the space utilization ratio of the warehouse can be improved; and besides, loading boxes can be conveyed to the plurality of goods sorting areas automatically through the goods sorting conveying line, manual carrying of the loading boxes is not needed, consumption of manpower resources is reduced, and the automation degree is high.

Owner:SHANGHAI QUICKTRON INTELLIGENT TECH CO LTD

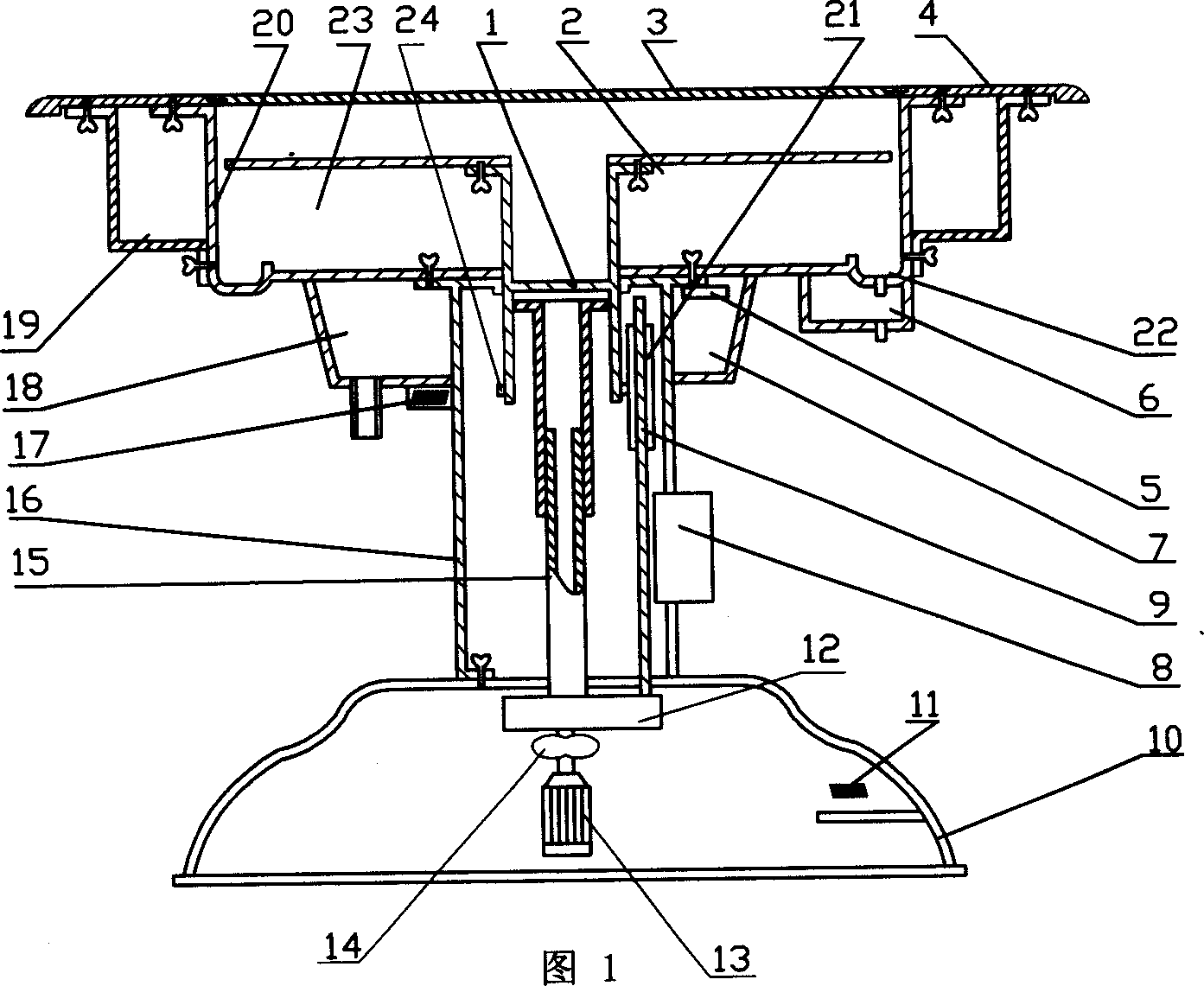

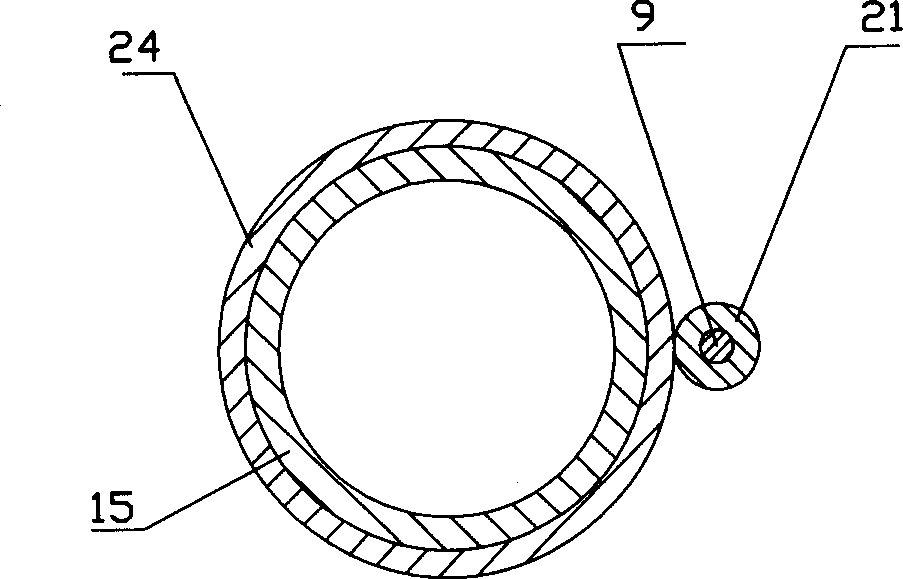

Multifuncational combined dining table

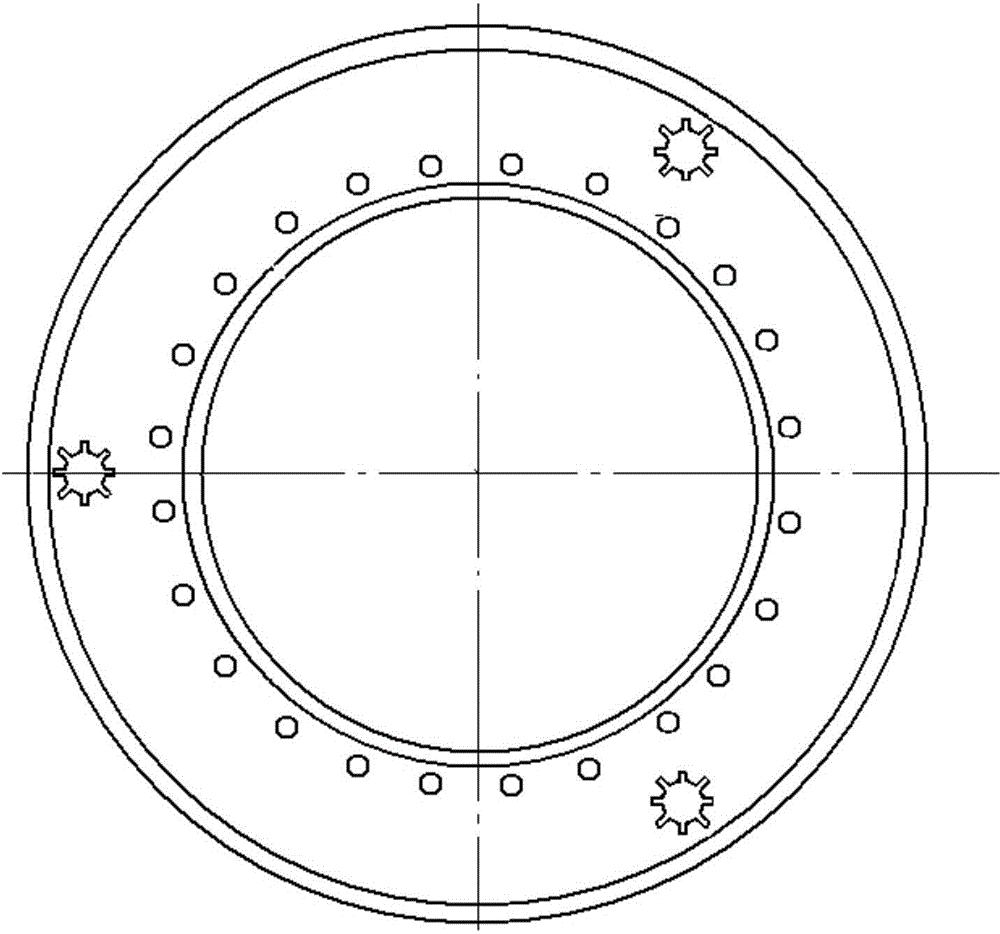

InactiveCN1528225AMake full use of the three-dimensional spaceReduce the use of areaServing tablesRevolvable tablesLap jointRing type

The present invention relates to a multifunctional combined dining-table, dividing into upper, middle and lower three portions. Its upper portion is dining-table top, middle portion is supporting column and lower portion is base seat, and said dining-table top is a circular plane formed from fixed table top and its matched movable table top, said movable table top is circular, and its fixed table top is circular ring type, and the lap-jointed portion of the fixed table top and movable table top in made into the mutually-matched step form. The fixed table toip is connected with supporting column by means of transition plate, and said supporting column is fixed on the base seat, and in the space enclosed with movable table top and transition plate a turntable disk is mounted, and its bottom portion is connected with power device positioned in the interior of base seat by means of gear and driving bar.

Owner:唐和平

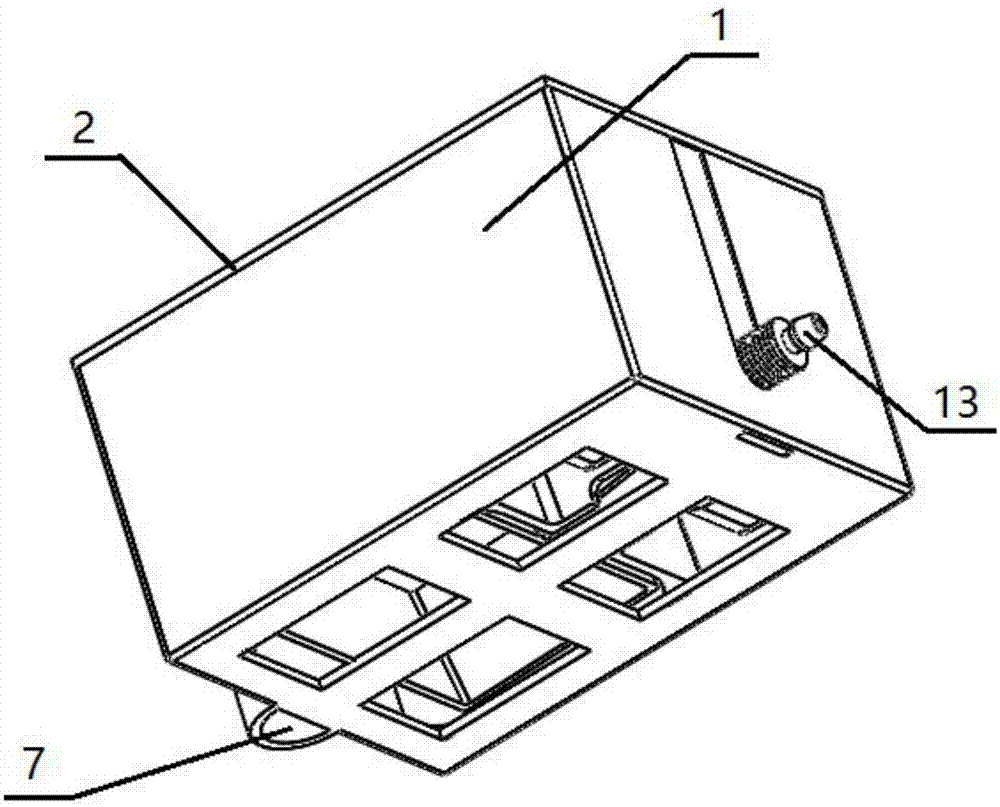

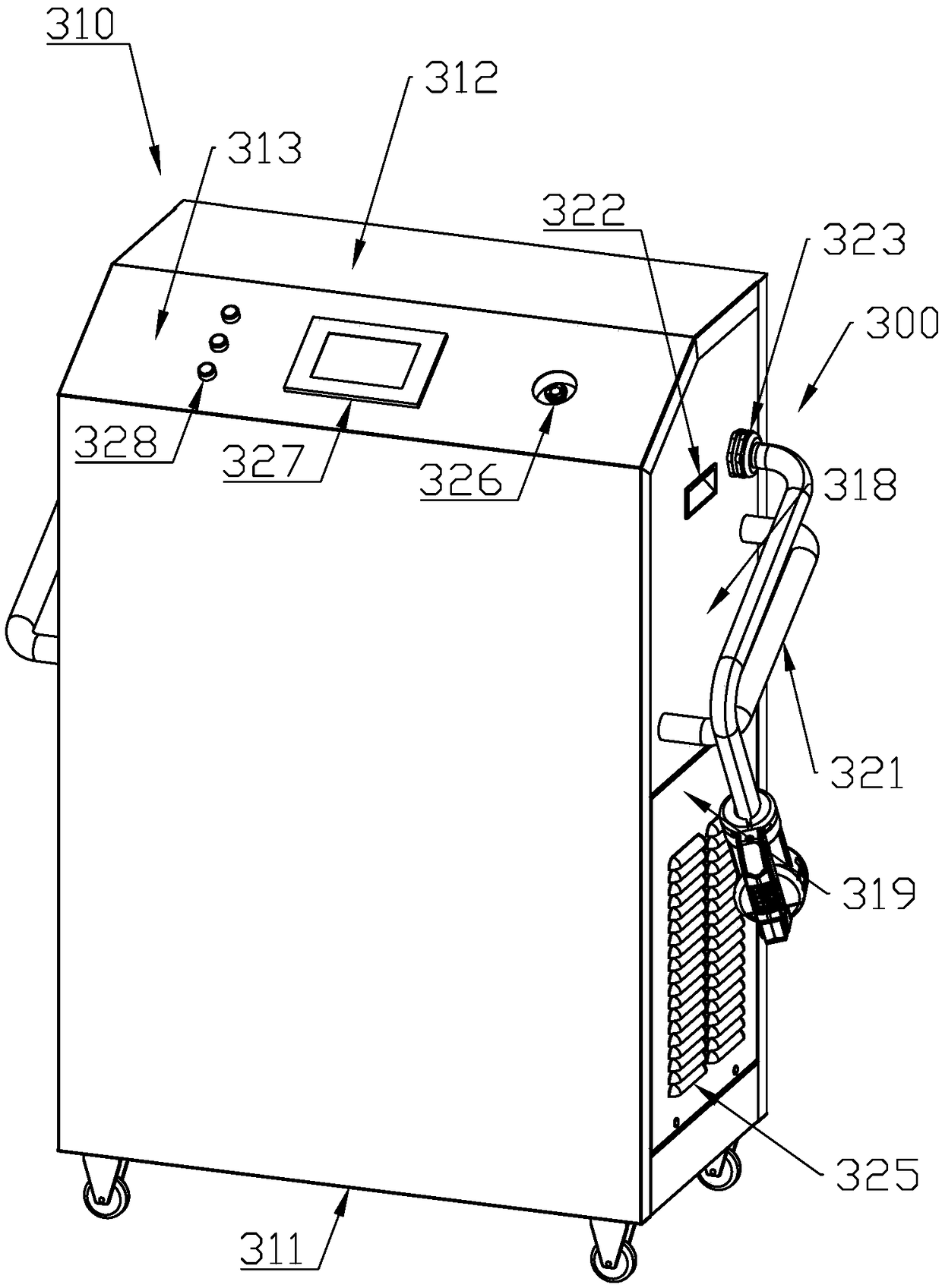

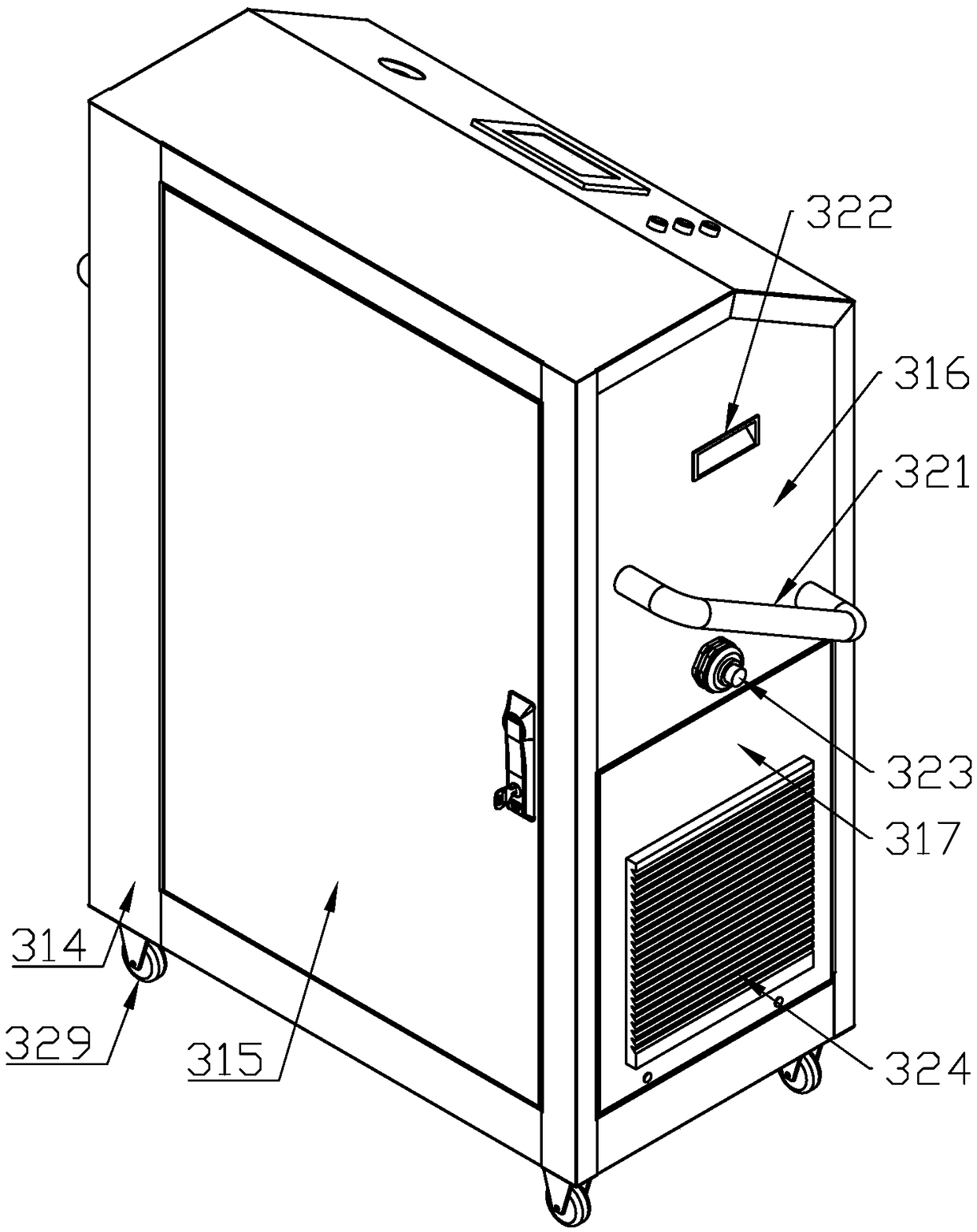

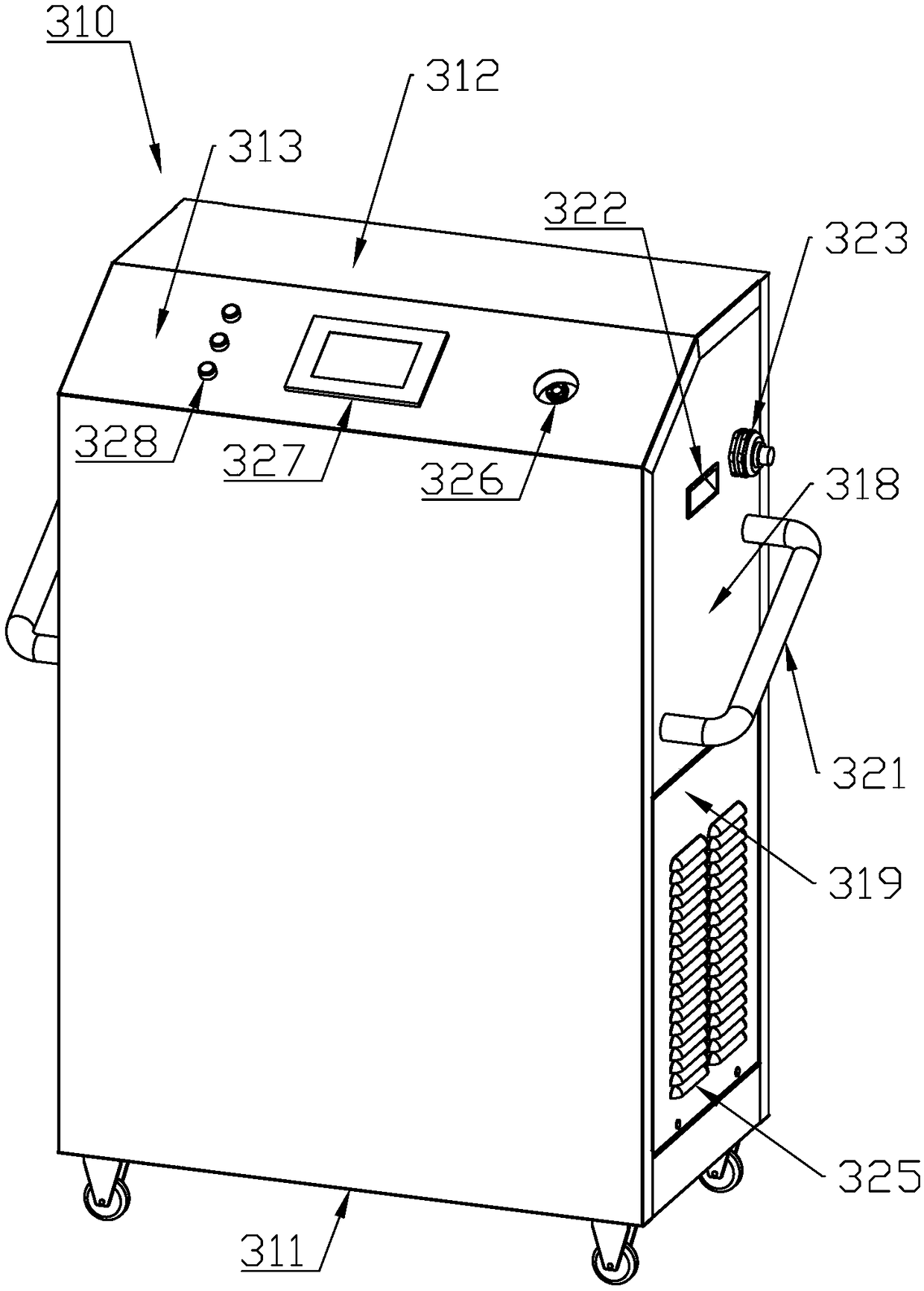

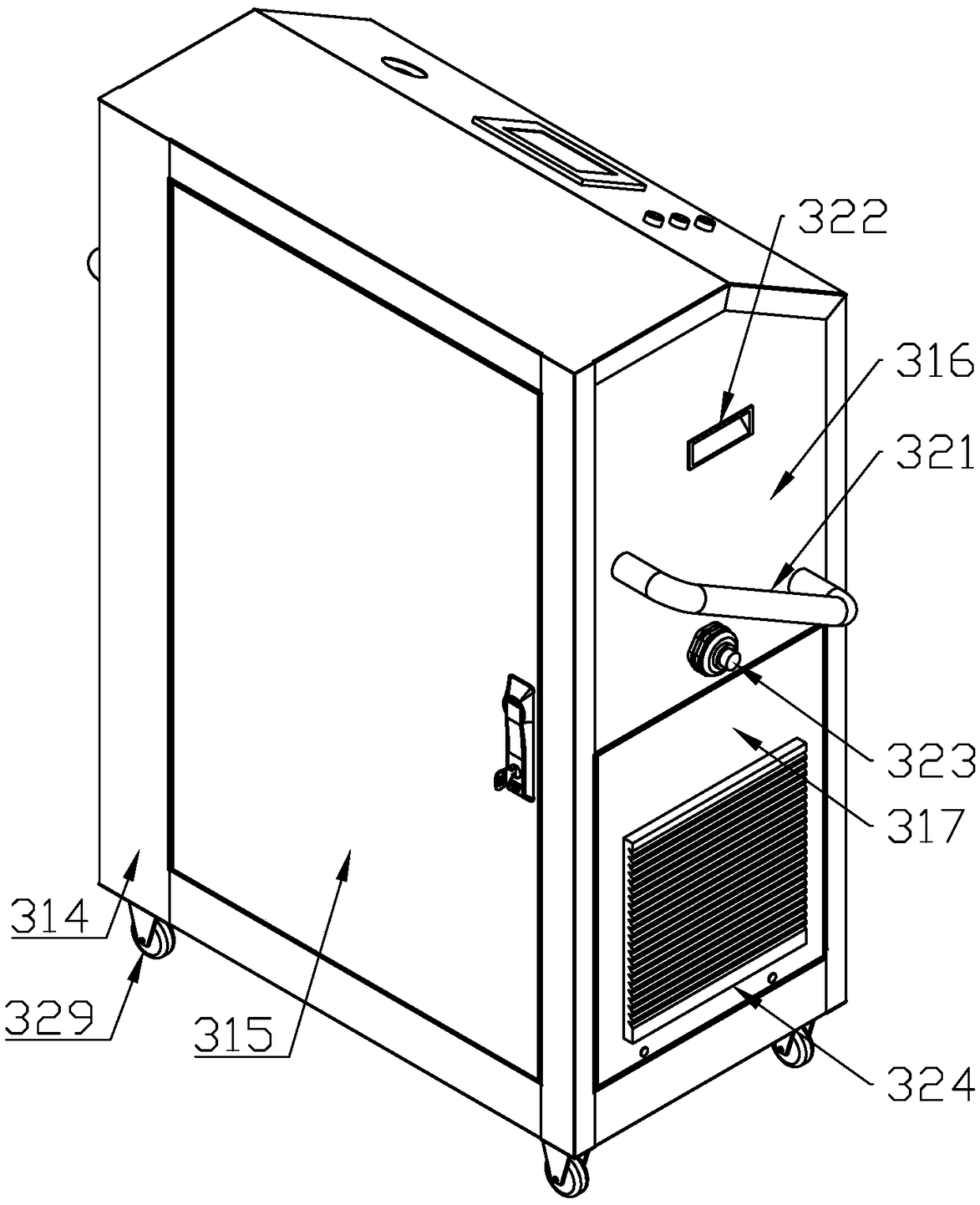

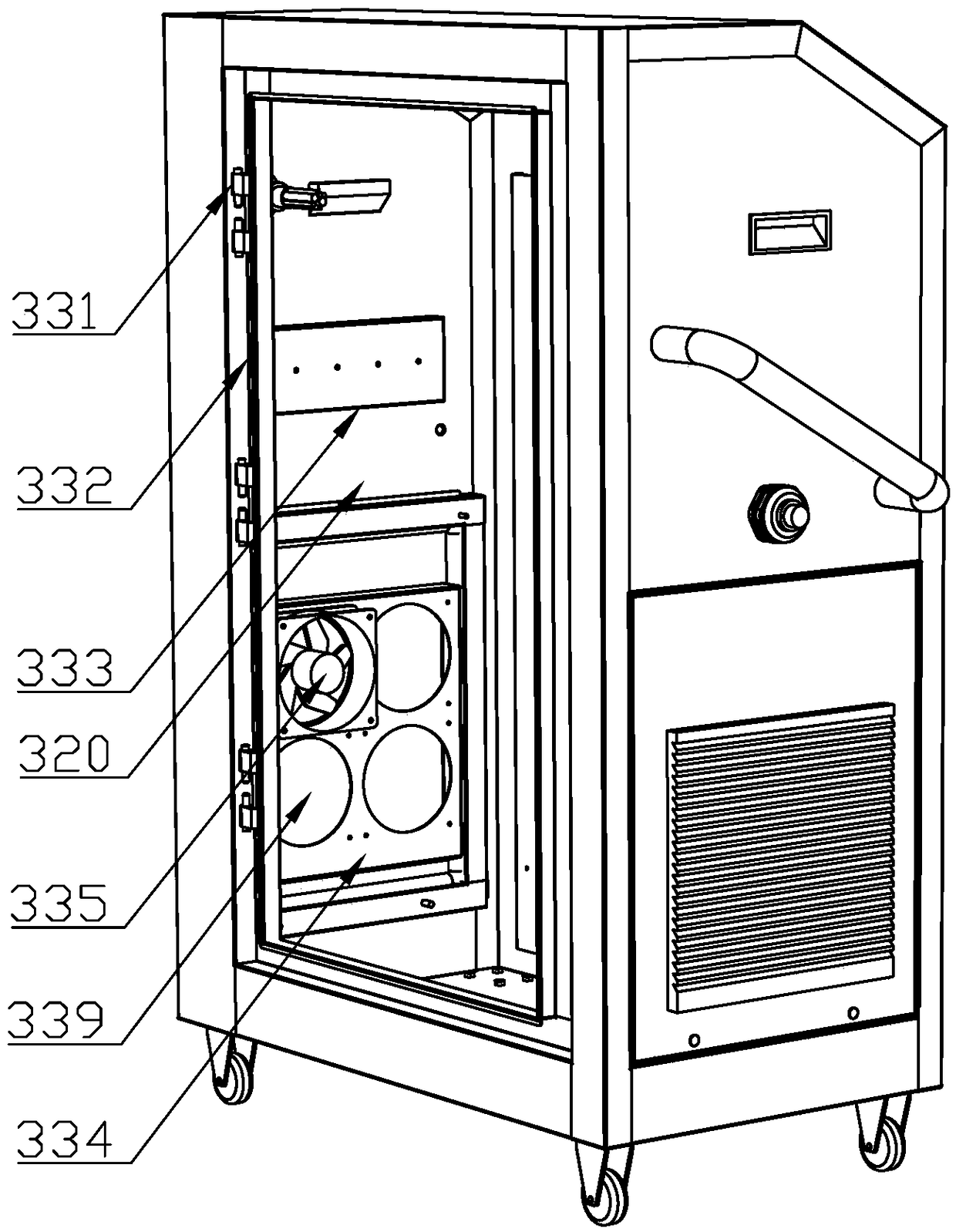

Portable charger

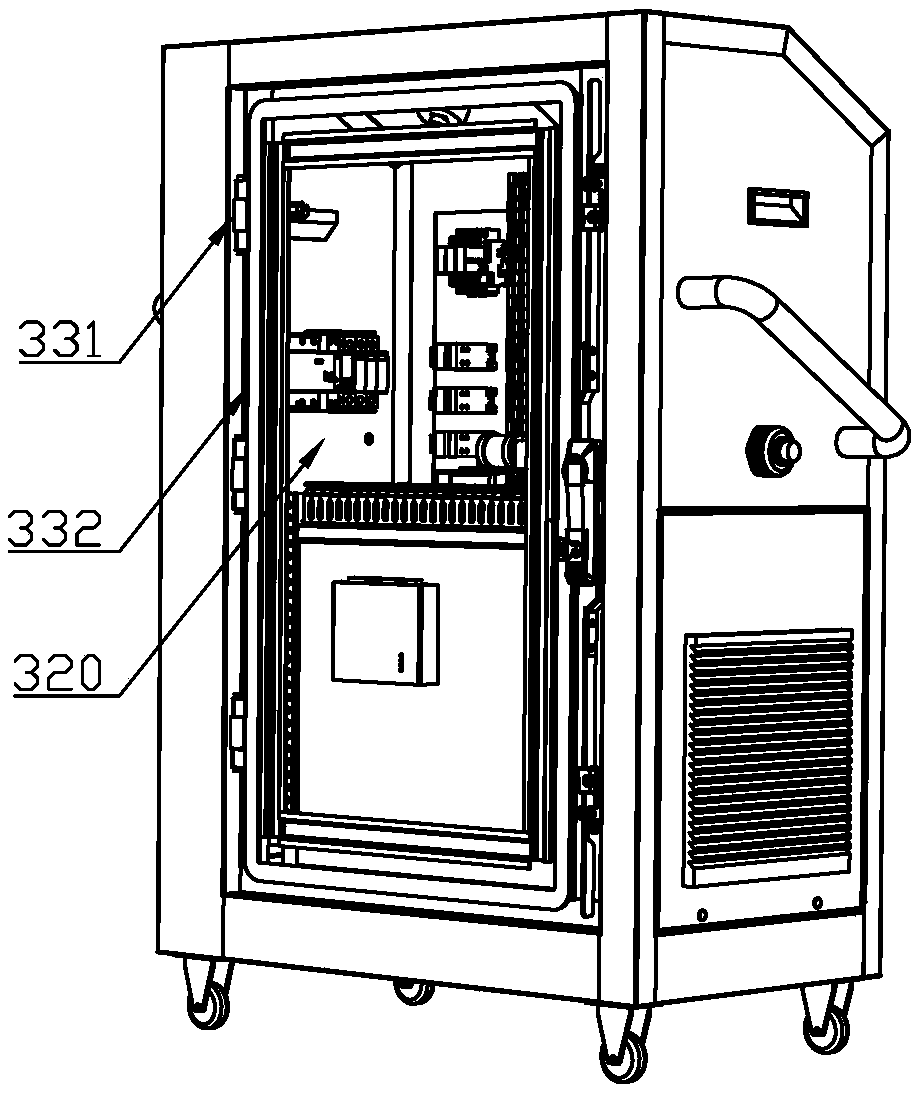

ActiveCN109017361AReduce loadLose weightModifications for power electronicsVehicular energy storageEngineeringDirect current

The invention discloses a portable charger, comprising a support mechanism, a ventilation module and a direct current output module built in the support mechanism. The support mechanism includes a body frame. The ventilation module comprises a ventilation module side plate, a ventilation module front cover plate, a ventilation module rear cover plate and at least one ventilation plug assembly. A portable charger is disclosed in which side plate restraints located on both sides and at the same relative height divide the receiving chamber into vent plug assembly slots consistent with the numberof vent plug assemblies to quickly plug or unload the vent plug assemblies as required. While meeting ventilation and heat dissipation requirements, minimize the load and dead weight of portable chargers. The main frame is in a flat stereoscopic configuration, which saves the floor area of the portable charger as much as possible, makes full use of the stereoscopic space, and improves the mobilityand flexibility of the portable charger.

Owner:AIA ELECTRIC PINGHU CO LTD

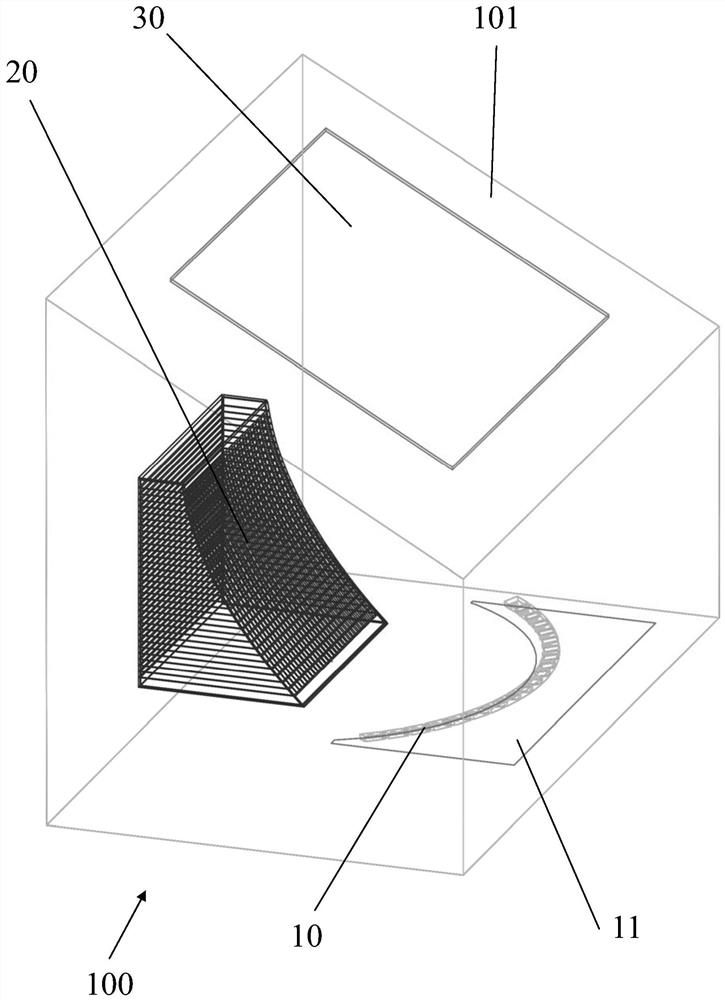

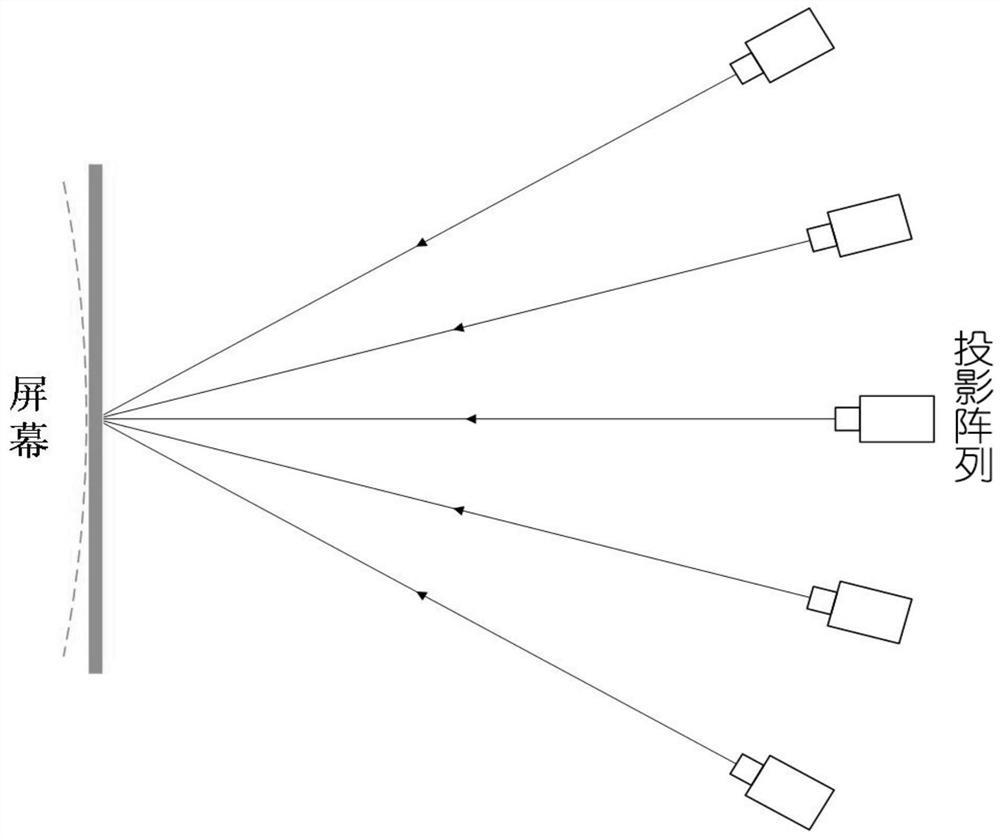

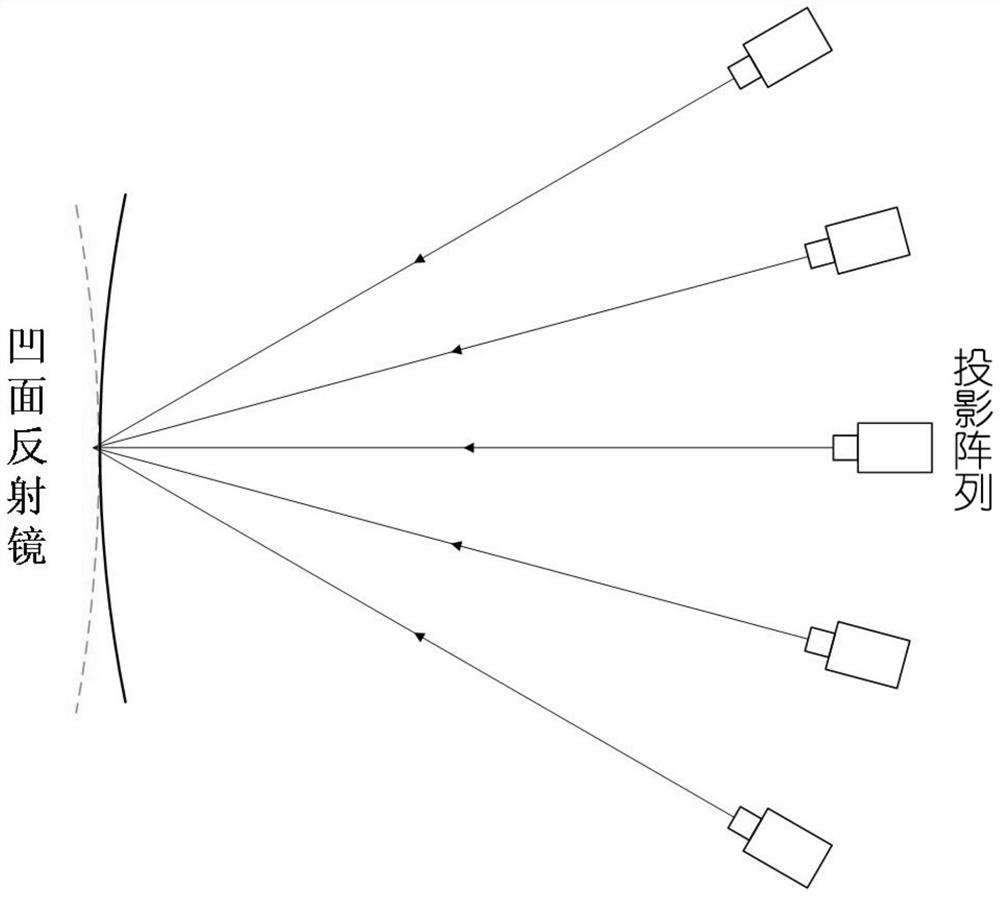

Curved surface transmission type 3D light field display system based on projection array

The invention relates to a curved surface transmission type 3D light field display system based on a projection array. The system comprises a projection array, a curved surface reflector and a screen; the projection array comprises a plurality of projectors mounted on an arc section bracket, the curved surface reflector is arranged on a light path of the projection array, and light emitted by the projectors is reflected to the screen through the curved reflector and is transmitted to the other side of the screen to be projected to generate a three-dimensional image. According to the curved surface transmission type 3D light field display system, the curved surface reflecting mirror is arranged on the light path of the projection array, the light emitted by the projectors is reflected to the screen and transmitted to the other surface of the screen to be projected to generate a three-dimensional image, the projection distance is increased, the breadth of the display system is expanded under the condition that the occupied area is not increased, the three-dimensional space is fully utilized, the size is small, and the system is convenient to carry and use.

Owner:深圳臻像科技有限公司

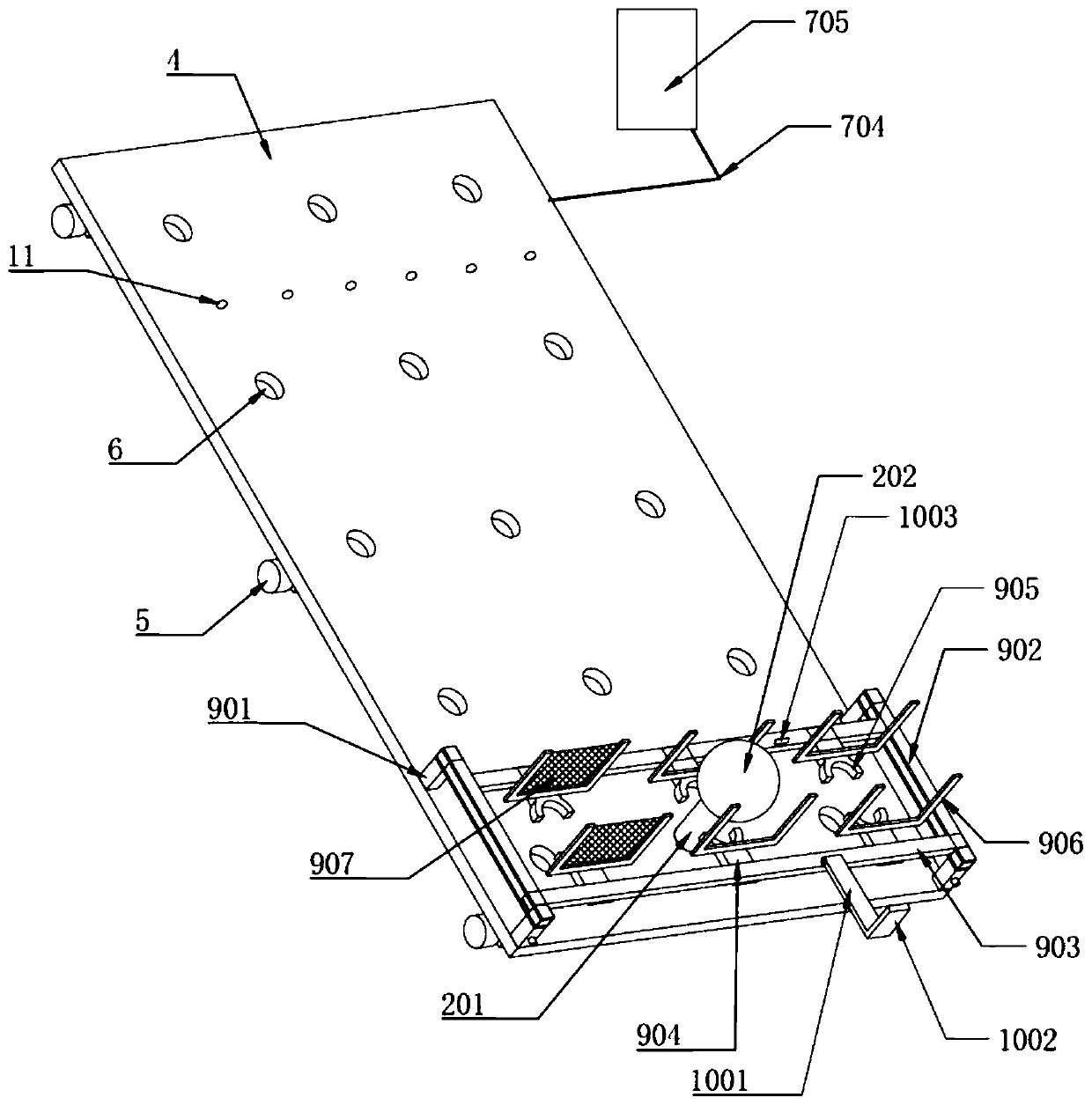

Placement rack for broccoli transportation

ActiveCN110921048AAvoid damageIncrease volumeLiving organism packagingRefrigerated goods vehicleAgricultural engineeringAgricultural science

The invention discloses a placement rack for broccoli transportation. The placement rack comprises a mounting frame, wherein horizontal track sets are evenly arranged on the mounting frame, each trackset comprises two symmetrically-arranged tracks, placing plates are slidably connected into the tracks, and the placing plates are evenly connected with rolling wheels connected with the tracks; uniformly distributed mounting holes are formed in the placing plates, fixed clamping devices for clamping rhizomes are arranged in the mounting holes, and a soilless culturing mechanism is further arranged below a fixed clamping device; the fixed clamping device comprises fixed clamping grooves, a sliding block is arranged in each fixed clamping groove, the sliding blocks are connected with the fixedclamping blocks, a spring is arranged between each sliding block and corresponding fixed clamping groove, and a conical guide part and a cylindrical part are arranged on the fixed clamping block; thesoilless culture mechanism comprises culture cavities arranged at the bottom parts of the mounting holes, a culture medium is arranged in each culture cavity, a nutrient solution is mixed in the culture medium, each culture cavity is connected with a drip irrigation pipe, and the drip irrigation pipe is connected with a drip irrigation mechanism. By means of the arrangement, the placement rack has the advantages of good fresh-keeping effect and convenient operation.

Owner:安徽云中生态农业开发有限公司

Method and apparatus for quickly changing road traffic situation by employing module design

Owner:钟宝驹

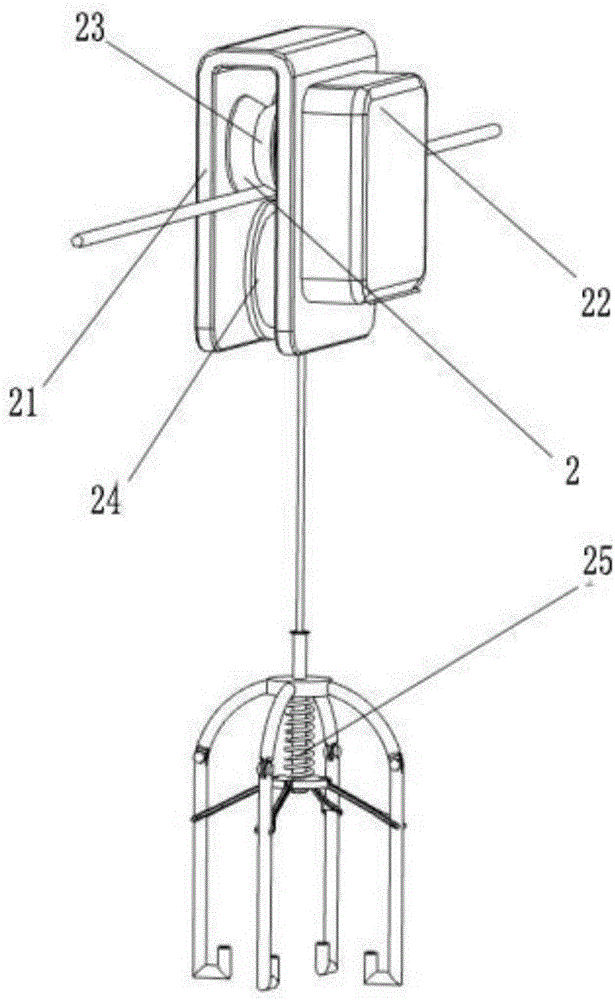

Full-automatic catering aerial conveying system

The invention discloses a full-automatic catering aerial conveying system. The full-automatic catering aerial conveying system comprises an aerial conveying net and hoisting devices, wherein the aerial conveying net covers a whole dining space; a dining table is arranged just below each node of the aerial conveying net; the plurality of hoisting devices are mounted on the aerial conveying net; and each hoisting device comprises a shell body, a control module, a pulley block, a coil and a claw, wherein the control module is arranged at the outer part of the shell body, the pulley block is arranged in the shell body and is connected onto the aerial conveying net in a sliding manner, the coil is arranged on the lower side in the shell body and the lower side of the coil is connected with the claw. The full-automatic catering aerial conveying system is composed of the aerial conveying net and the hoisting devices, is simple in structural design, convenient to operate and high in practicability and has a very good generalization performance.

Owner:GUANGXI UNIV

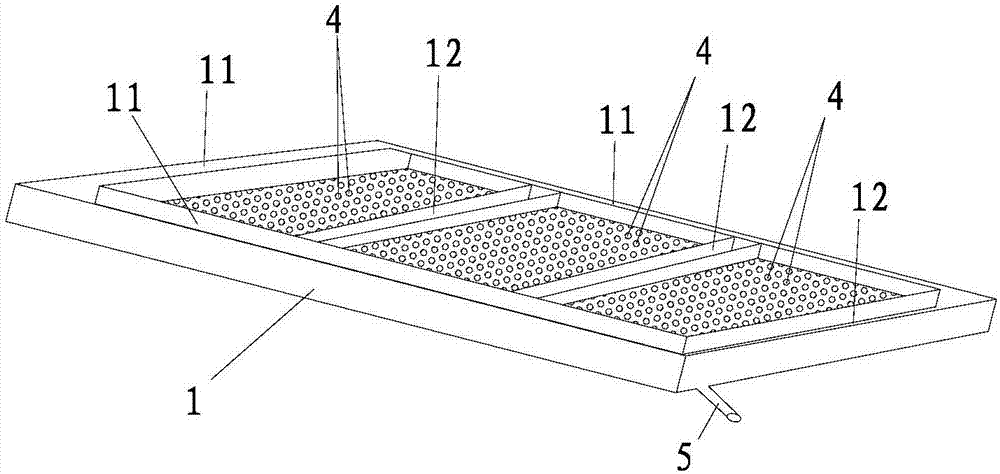

Combined type three-dimensional plant cultivation device

PendingCN107333583ASimple structureFlexible splitSaving energy measuresCultivating equipmentsEngineeringPlant cultivation

The invention discloses a combined type three-dimensional plant cultivation device. The combined type three-dimensional plant cultivation device comprises a bottom plate as well as a plurality of vertical peripheral plates and a plurality of vertical partition plate which are detachably mounted on the bottom plate; a plurality of cultivation grooves with upward openings are defined by the bottom plate, the vertical peripheral plates and the vertical partition plates in an enclosing way; the vertical partition plates are arranged between the adjacent cultivation grooves and can be drawn out from bottom to top; and a plurality of small grooves with root control effects are formed in the plate surface, facing towards the cultivation grooves, of the bottom plate, the plate surfaces, facing towards the cultivation grooves, of the vertical peripheral plates as well as the plate surfaces, facing towards the cultivation grooves, of the vertical partition plates correspondingly. The combined type three-dimensional plant cultivation device is convenient in plant cultivation.

Owner:中山市海枣椰农业科技有限公司

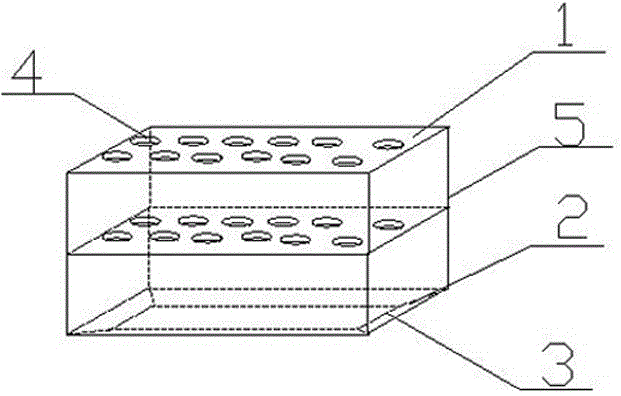

Laminated test tube apparatus convenient for placing test tubes

InactiveCN105854974AMake full use of the three-dimensional spaceSave spaceTest tube stands/holdersBaseboardEngineering

The invention discloses a laminated test tube apparatus convenient for placing test tubes. The apparatus comprises a top board, a baseboard and a middle board which are sequentially arranged in a laminated manner from top to bottom, the four corners of each of the top board, the baseboard and the middle board are provided with connecting portions, the connecting portions of the top board are connected with the connecting portions of the middle board through connecting rods, and the connecting portions of the middle board are connected with the connecting portions of the baseboard through connecting rods; and the connecting portions are cylindrical cavities, and the middle portion of every connecting portions is provided with a separator board. The top board, the middle board and the baseboard can be arranged in a laminated manner, the quantity of the middle board can be one or above, the middle board, the top board and the baseboard are respectively provided with through holes for placing test tubes, and the test tube apparatus can be designed to have a multilayer structure as needed in order to realize placement of a large amount of test tubes.

Owner:CHENGDU EMPEROR MEDICAL TECH CO LTD

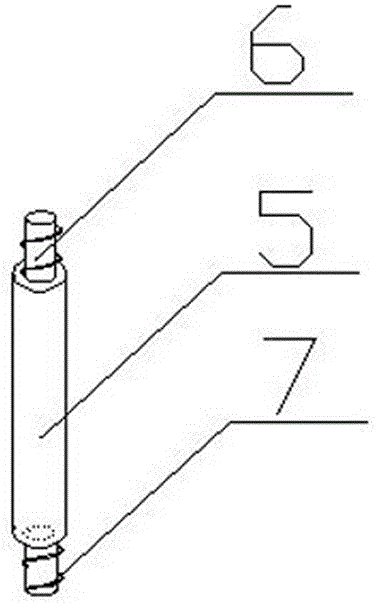

Supporting mechanism for portable charger

PendingCN108790904ASmall footprintImprove mobility and flexibilityElectric propulsionEngineeringCaster

Owner:AIA ELECTRIC PINGHU CO LTD

Micro-nano porous bismuth electrode and preparation method thereof

InactiveCN102706937BAchieve recyclingThe preparation method is simple and environmentally friendlyMaterial electrochemical variablesMicro nanoAlloy

The invention discloses a micro-nano porous bismuth electrode and a preparation method thereof. The preparation method for the micro-nano porous bismuth electrode comprises the following steps: preparing a tin bismuth alloy, wherein a mass ratio of tin to bismuth in the tin bismuth alloy is 1:(0.5-6); processing appearance of the tin bismuth alloy, thereby obtaining a tin bismuth alloy electrode; performing alloy tin-melting treatment on the tin bismuth alloy electrode according to an electrochemical method, and arranging a tin-melting potential between corrosion potentials of metal tin and bismuth, thereby obtaining the micro-nano porous bismuth electrode; and if necessary, performing anodic oxidation treatment on the micro-nano porous bismuth electrode, thereby obtaining the micro-nano porous bismuth electrode with suitable pores and size. The preparation method provided by the invention has the advantages of simple technology, environmental protection and zero pollution; the production cost of the micro-nano porous bismuth electrode is low; and the obtained micro-nano porous bismuth electrode has the advantages of strong adjustability of microstructure, flexible and controllable macroscopic shape and size, big specific surface area, high detection sensitivity and application to the detection for trace heavy metal ions and trace organic matters in liquid.

Owner:SUN YAT SEN UNIV

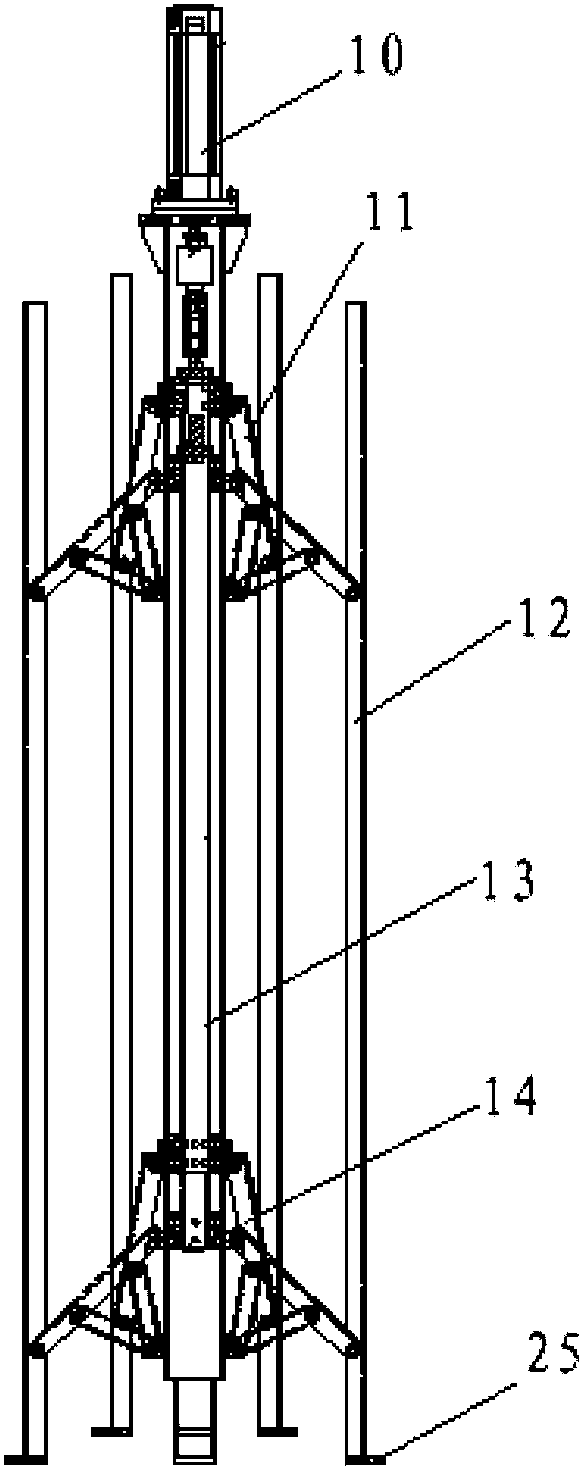

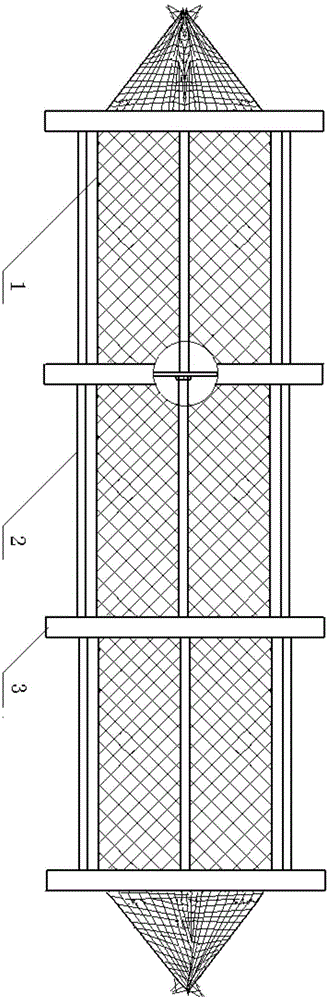

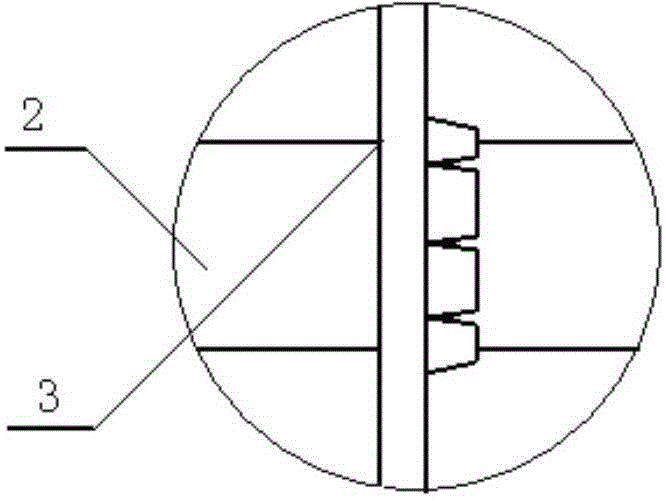

Raising method for sea cucumber by using net cage under the sea

InactiveCN104938366AReduce manufacturing costMake full use of the three-dimensional spaceClimate change adaptationPisciculture and aquariaReciprocating motionEngineering

The invention provides a raising method for a sea cucumber by using a net cage under the sea. A net cage frame is composed of an annular net cage support plate and rod-shaped bodies such as bamboo rods or sealed plastic pipes, the outer ring of the net cage frame is sewed with cylindrical netting, and the net cage frame with two open ends is formed. A base curtain is hung in a net cage inner chamber, two ends of the frame-type net cage are tightened by using connecting ropes and are connected with a raft body, a sandbag is arranged on the raft body, and a sea cucumber raising device under the sea is formed. By means of the device, impact force of tides on the frame-type net cage can be effectively used, horizontal reciprocating motions in two directions under the sea can be achieved every day, various kinds of nutritive materials under the sea can be acquired by the sea cucumber in a large-area mode, the frame-type net cage can be effectively prevented from being caught in silt, a certain distance between the outer ring of a net cage support plate and the netting is formed, and the netting is prevented from being broken due to friction of the undersea silt.

Owner:敖志辉

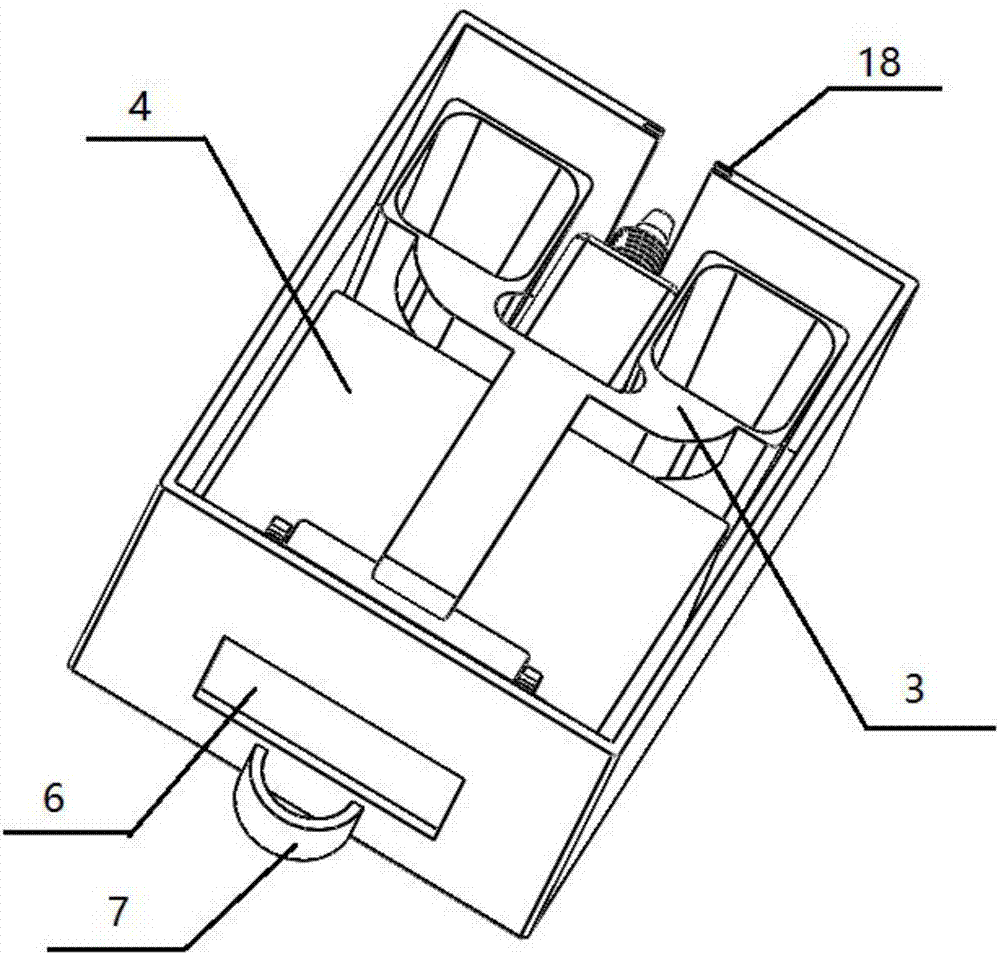

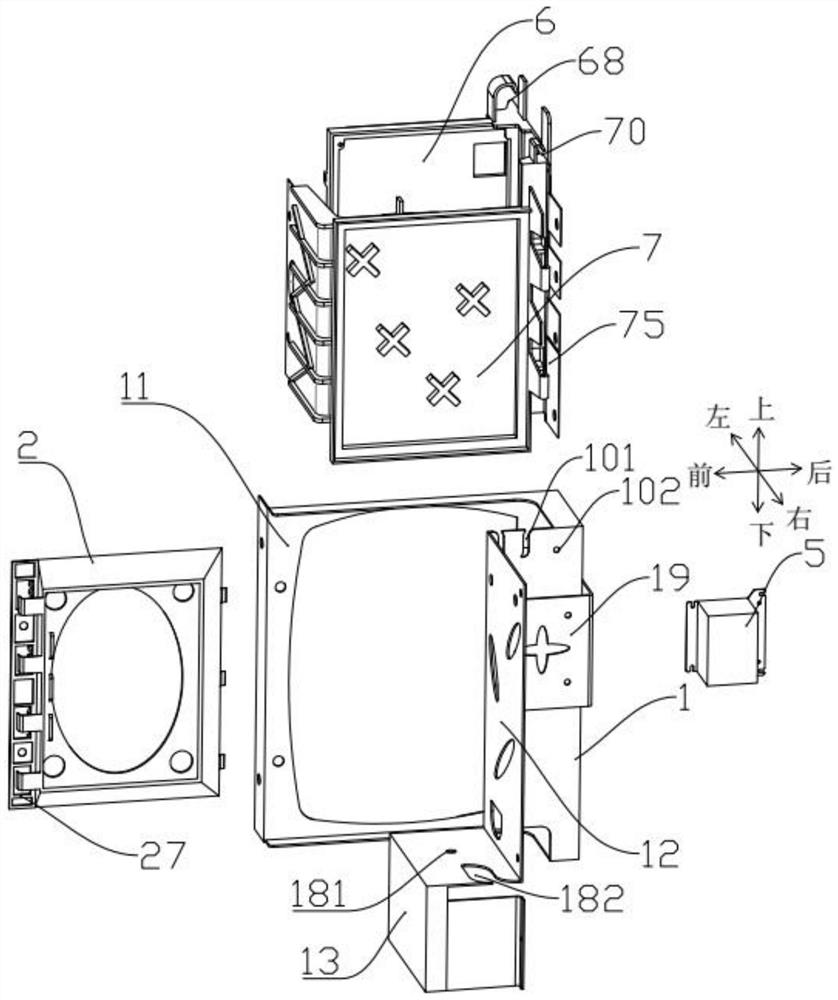

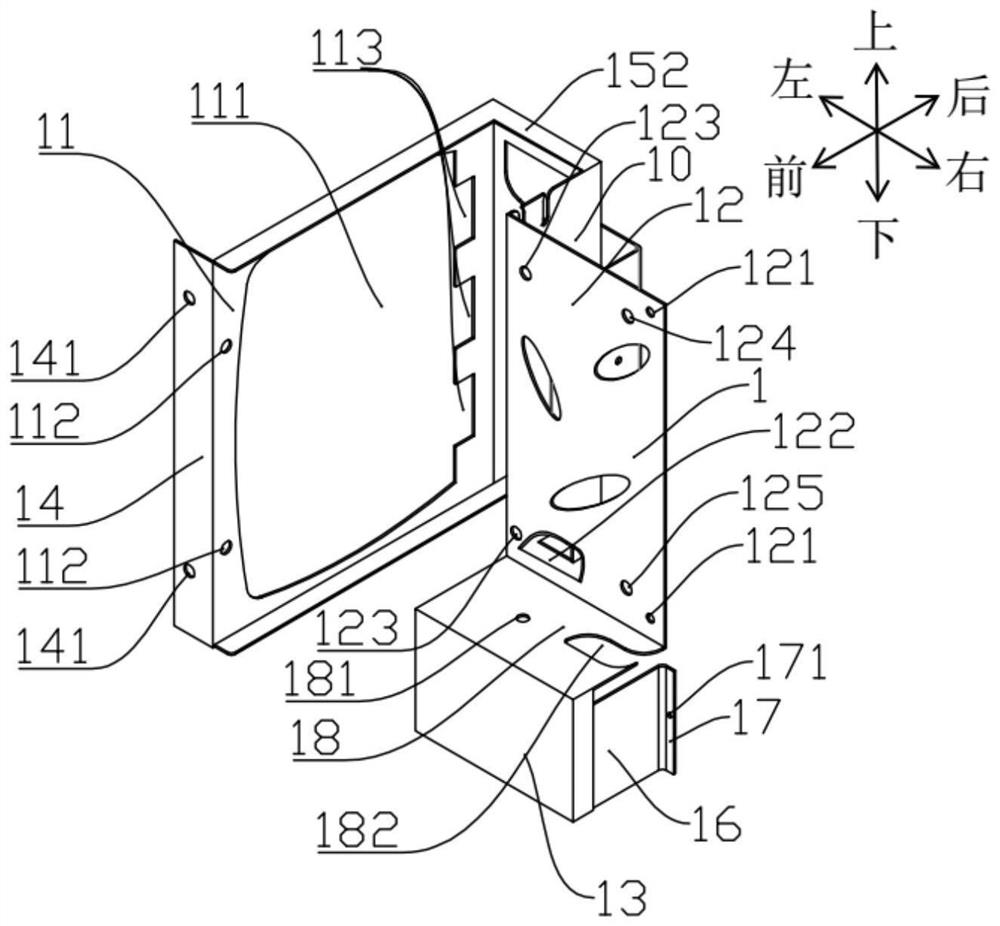

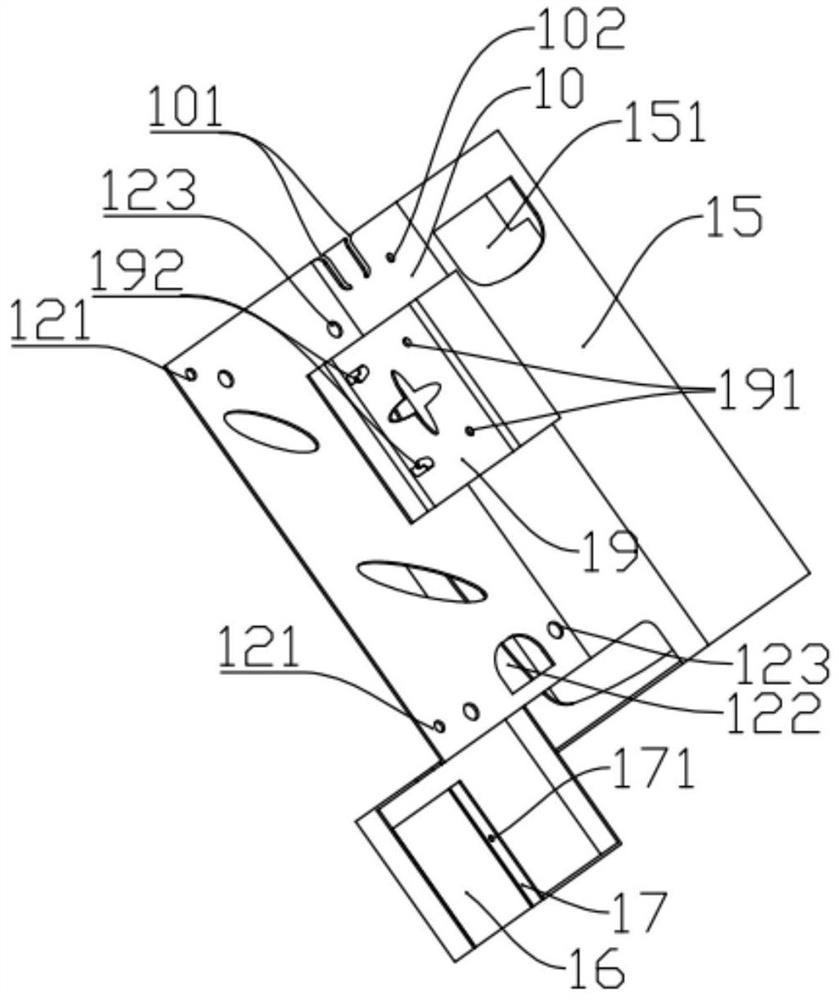

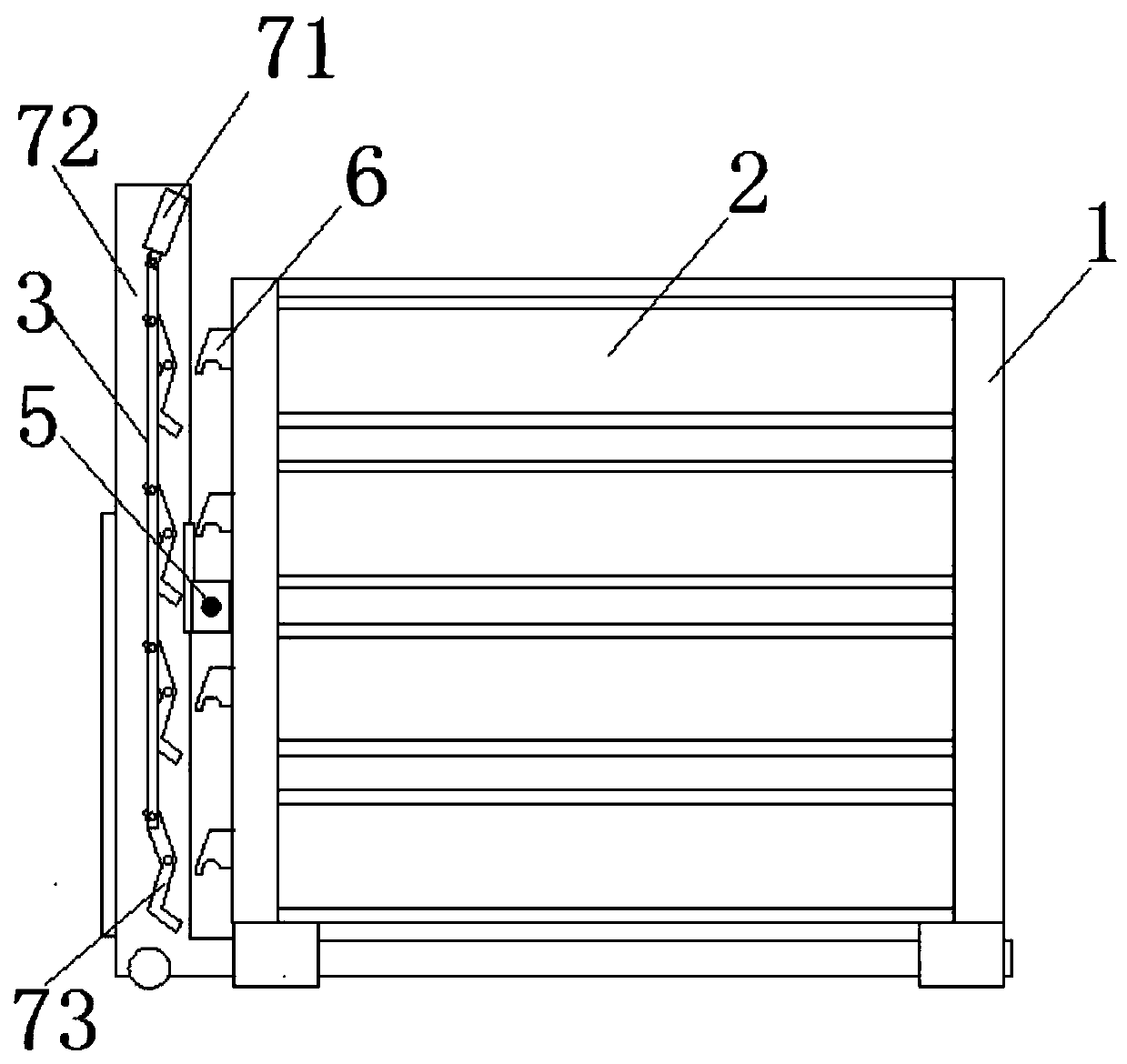

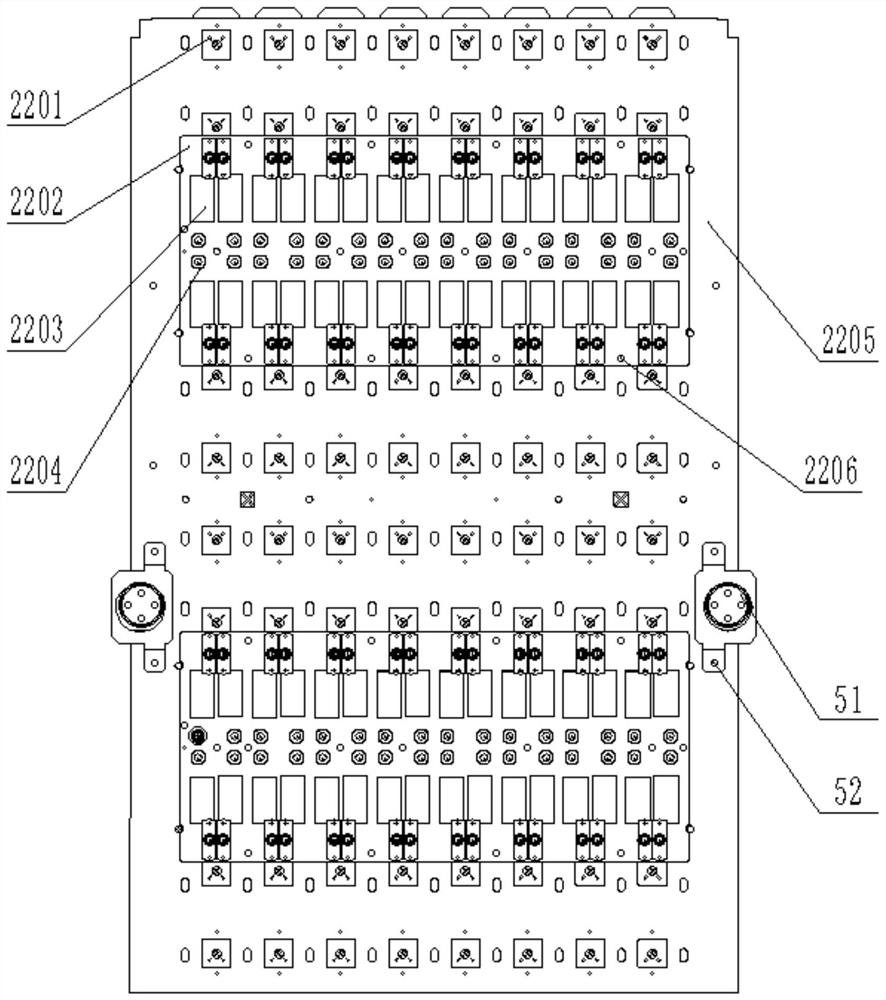

Electric control box and air conditioner

ActiveCN111219860BMake full use of the three-dimensional spaceReduce floor areaMechanical apparatusElectric controlElectrical and Electronics engineering

The present invention provides an electric control box, the electric control box includes a first angular installation box and a second angular installation box, the first angular installation box is provided with a second installation cavity for installing electrical components; The second angular installation box is provided with a third installation cavity for installing electrical components; the first angular installation box is connected with the second angular installation box to form a ring-shaped installation box, and the second installation cavity and the third The installation cavities are parallel; the electric control box of the present invention includes a first angular installation box and a second angular installation box, the first angular installation box and the second angular installation box are connected to form a ring-shaped installation box, and the installation The second installation cavity with electrical components is parallel to the third installation cavity. The electric control box of the present invention can install circuit components in layers, on the one hand, it can make full use of the three-dimensional space of the electric control box, and reduce the plane area of the electric control box; Stable installation.

Owner:NINGBO AUX ELECTRIC +1

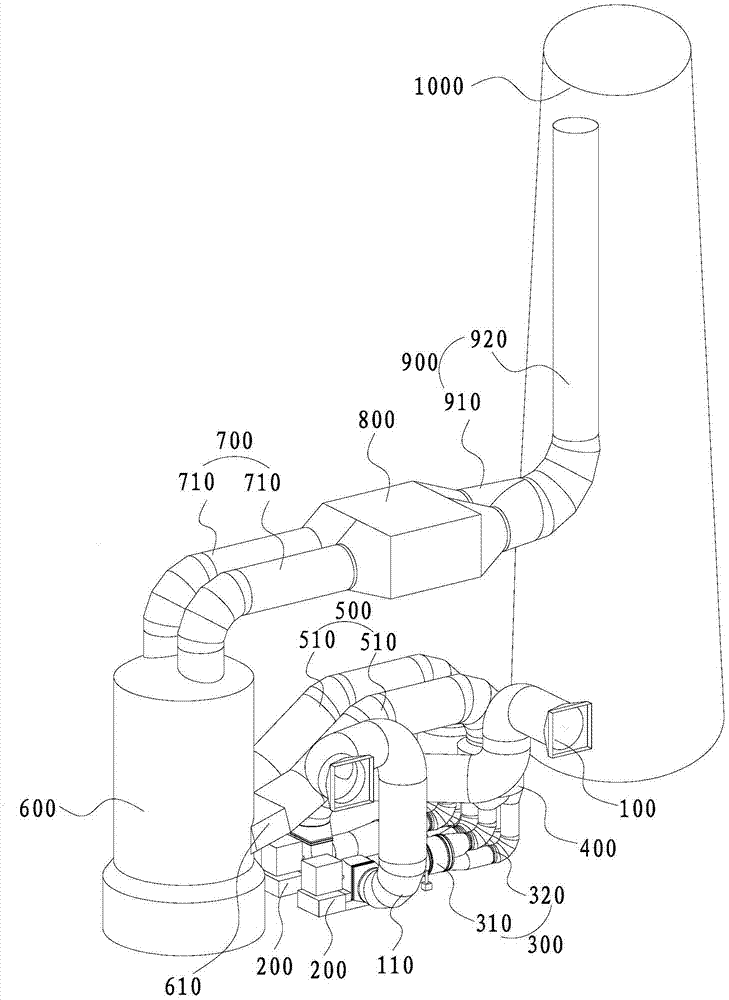

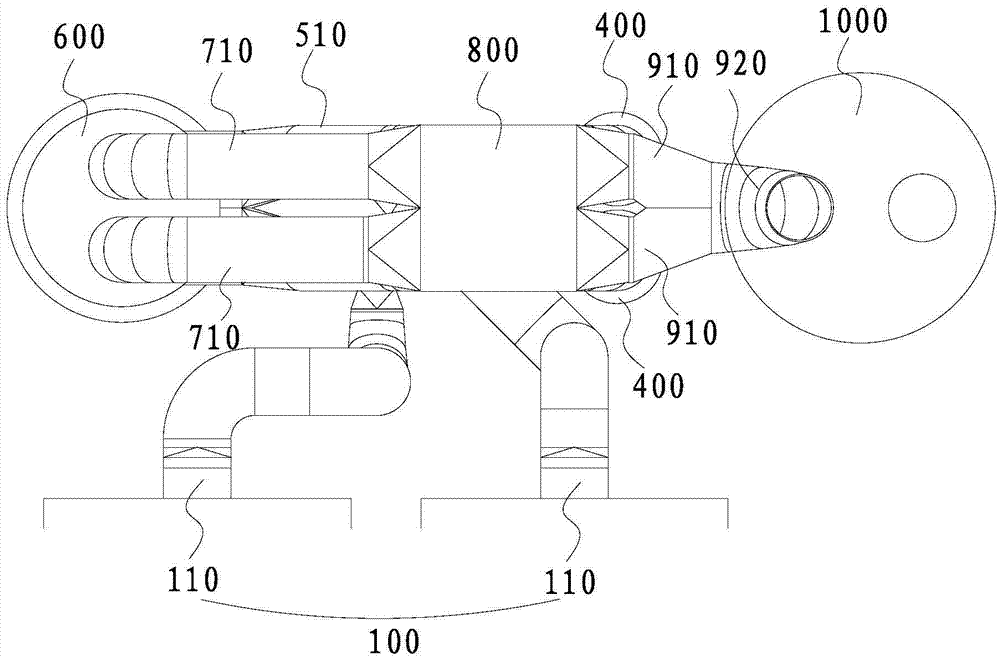

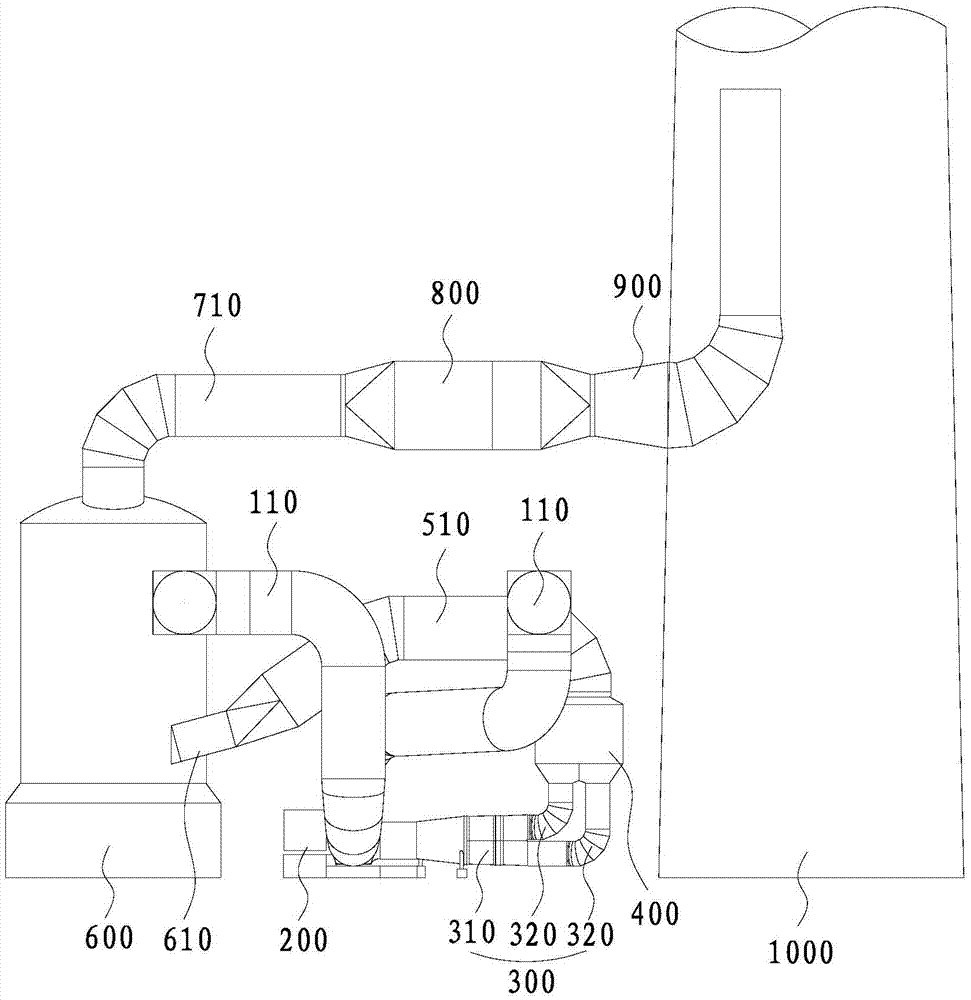

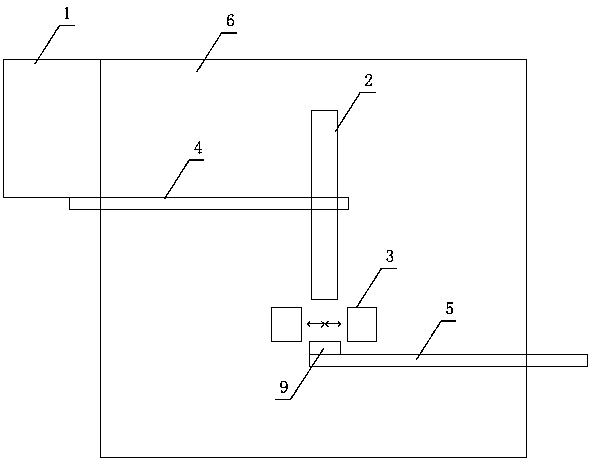

Rear flue gas system combined arrangement structure of two outlets of dust collector and double rows of induced draft fans

The invention discloses a rear flue gas system combined arrangement structure of two outlets of a dust collector and double rows of induced draft fans. The combined arrangement structure comprises the double rows of induced draft fans connected with the two outlets of the dust collector, two flue gas waste heat recovering devices correspondingly connected with the double rows of induced draft fans, a desulfurizing absorption tower connected with the two flue gas waste heat recovering devices, a wet electric dust collector connected with the desulfurizing absorption tower, and a chimney connected with the wet electric dust collector; the center lines of the double rows of induced draft fans, the two flue gas waste heat recovering devices, the desulfurizing absorption tower, the wet electric dust collector and the chimney which are sequentially connected are all positioned on the same plane; and the wet electric dust collector is arranged over the induced draft fans. The devices behind the dust collector are arranged in a space combined manner linearly, so that the devices are arranged more compactly, the occupied area is reduced, and the lengths of connecting flues are reduced.

Owner:CHINA ENERGY ENG GRP GUANGDONG ELECTRIC POWER DESIGN INST CO LTD

A filling food forming machine

ActiveCN105724510BAvoid occupyingMake full use of the three-dimensional spaceDough shaping and dividing combinationDough processingVertical planeMolding machine

The invention relates to the field of food processing and particularly relates to a stuffed product molding machine. The stuffed product molding machine comprises a wrapper feeding device, a stuffing filling device, a molding device and a conveyor belt, wherein the conveyor belt comprises a wrapper conveyor belt and a finished product conveyor belt; the wrapper conveyor belt and the finished product conveyor belt are mounted on a bracket; a height difference is formed between the wrapper conveyor belt and the finished product conveyor belt; the stuffing filling device and the molding device are arranged between the wrapper conveyor belt and the finished product conveyor belt; the stuffing filling device and the molding device are arranged on the same vertical plane; a stuffing filling station is formed on the stuffing filling device and a molding station is formed on the molding device; and horizontal projections of the stuffing filling station and the molding station are mutually overlapped. The stuffing filling device and the molding device are arranged on the same vertical plane, namely the horizontal projections of the stuffing filling station and the molding station are mutually overlapped. The stuffed product molding machine has the advantages that the two stations can be overlapped in space and the stereoscopic space is sufficiently utilized, so that a condition that excessive stations of equipment exist and more space is occupied is avoided.

Owner:CHENGDU SOONTRUE MECHANICAL EQUIP CO LTD

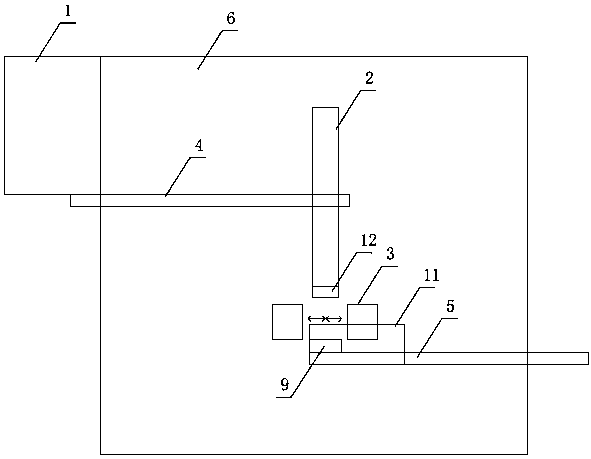

Method for pruning tomato bearing branch leaning to one side

ActiveCN102273375BIncrease the number of spikesIncrease productionHorticultureThree-dimensional spaceEngineering

The invention discloses a method for pruning tomato bearing branches leaning to one side, comprising the following steps of: arranging a lifting rope vertical to ground surface beside rhizome of each plant; cultivating 5-8 bearing branches on each plant from down to up by adopting a continuous pinching and swapping method, and dragging each bearing branch onto the lifting rope of a northward adjacent plant of the plant to cause the included angle between each bearing branch and the ground surface to be 30-45 degrees. By adopting the method, the total inflorescence number of an individual plant can be improved, sunlight can be ensured to directly irradiate onto a tomato plant, photosynthesis is carried out more fully, carbohydrate accumulated on leaves of the bearing branches is easy to return into fruits, the fruits can get larger, and yield is improved. The phenomenon that the bearing branches drop and then are broken as the fruits expand and weight is increased in the later expanding stage of the fruits can be avoided. Plant height can be controlled, three-dimensional space in a shed can be fully utilized, the problem of falling seedling for multiple times can be solved, and labour can be reduced. Field transmitting condition can be improved, morbidity of the fruits can be reduced, the fruits also can be ensured to uniformly develop and be bright and glossy, and high-qualityfruit rate is improved.

Owner:SHANDONG SHOUGUANG VEGETABLE IND GRP

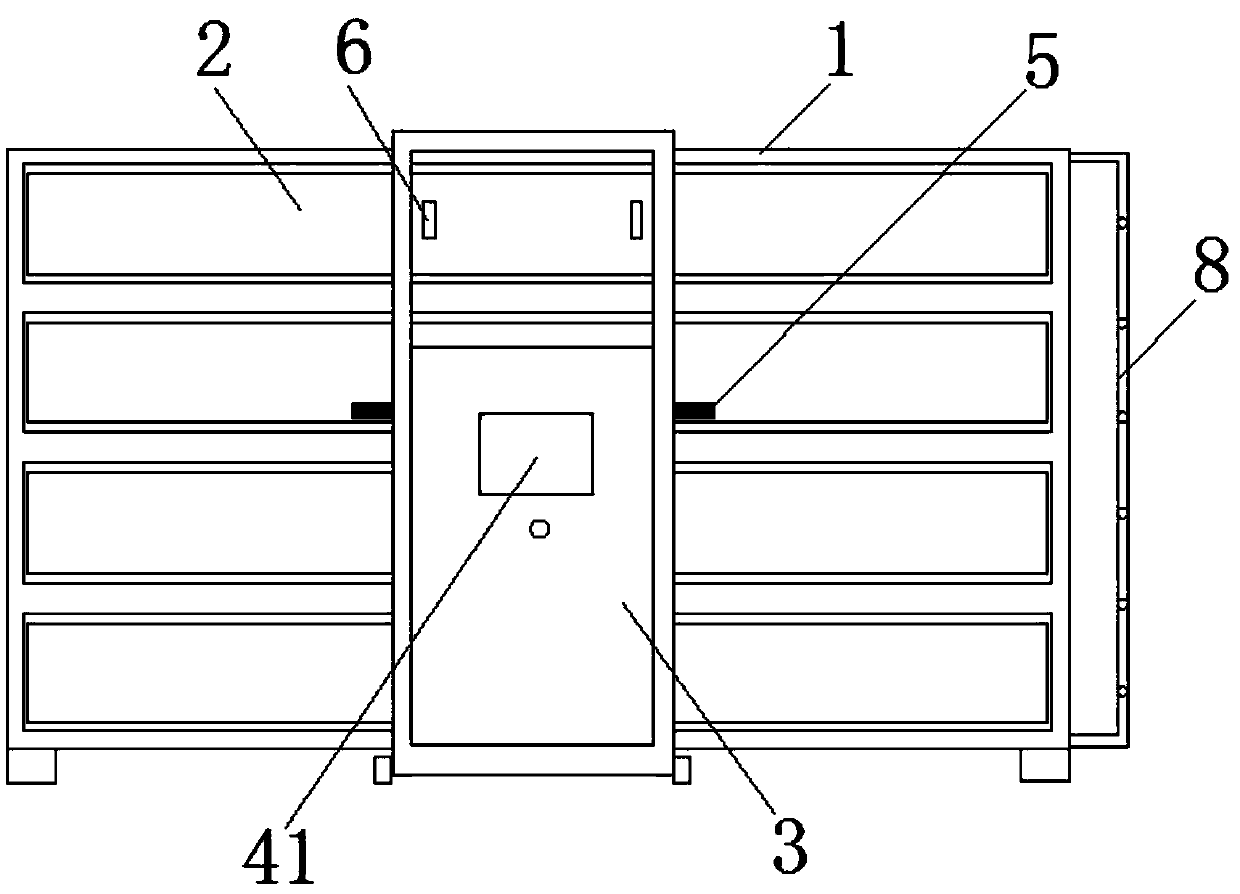

Three-dimensional bottle washing machine and bottle washing method

The invention discloses a stereoscopic bottle washing machine and a bottle washing method, which have a good bottle washing effect and occupy a small area. The bottle washing machine comprises a first chain wheel and a second chain wheel which are horizontally arranged; the second chain wheel is positioned below the first chain wheel; one group of chain wheels also comprises a third chain wheel and a fourth chain wheel which are vertically arranged; a bottle feeding mechanism and a bottle discharging mechanism are respectively arranged outside the first chain wheel; a chain between the first chain wheel and the third chain wheel is a bottle body soaking section; a rack corresponding to the bottle body soaking section is provided with a first water spraying mechanism for spraying water into a bottle body; a chain between the third chain wheel and the second chain wheel is a bottle body water pouring section; the rack corresponding to the second chain wheel is provided with a second water spraying mechanism for spraying water to the outer wall of the bottle body and spraying water into the bottle body. The method mainly applies the bottle washing machine to wash the bottle body. The bottle washing machine disclosed by the invention has a simple structure, is reasonably laid out and saves the space.

Owner:LUZHOU HUIJIANG MACHINERY MFG

Tire handling and depalletizing system and palletizing method for tire storage

ActiveCN103434850BFully automated processingLarge storage capacityStacking articlesDe-stacking articlesEngineeringHandling system

The invention discloses a tire carrying and destacking-stacking system, which comprises a support mechanism, a carrying mechanism and a power device, wherein the support mechanism comprises a first longitudinal beam and a second longitudinal beam which are arranged in parallel, and a support vertical column for supporting the first longitudinal beam and the second longitudinal beam; the carrying mechanism comprises a movable transverse beam and a carrying manipulator; the movable transverse beam stretches across the first longitudinal beam the second longitudinal beam, and is in slide fit with the first longitudinal beam and the second longitudinal beam along the longitudinal directions of the two longitudinal beams; the carrying manipulator is arranged on the movable transverse beam, and is in slide fit with the movable transverse beam along a transverse direction; the carrying manipulator comprises a grasping part used for grasping a tire, and a lifting assembly for controlling the grasping part to move vertically; the power device comprises a longitudinal power device used for driving the movable transverse beam to move along a longitudinal direction, and a transverse power device used for driving the carrying manipulator to move along a transverse direction. According to the tire carrying and destacking-stacking system, full automation of tire carrying and destacking-stacking is realized.

Owner:青岛科捷机器人有限公司

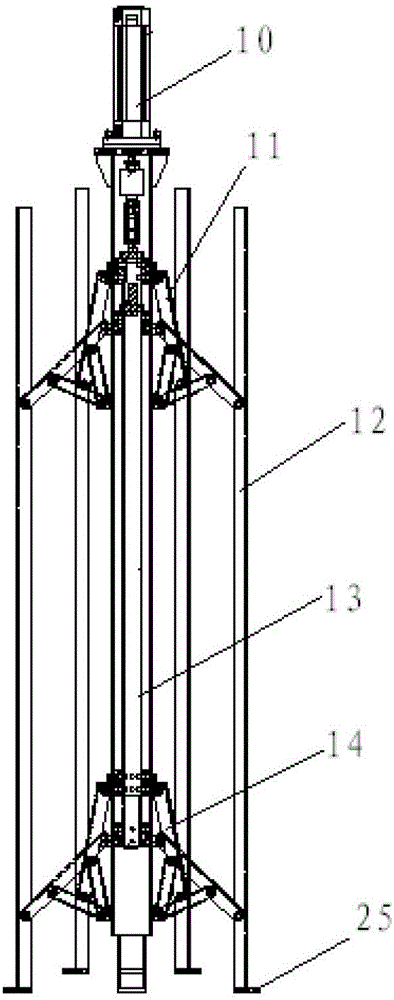

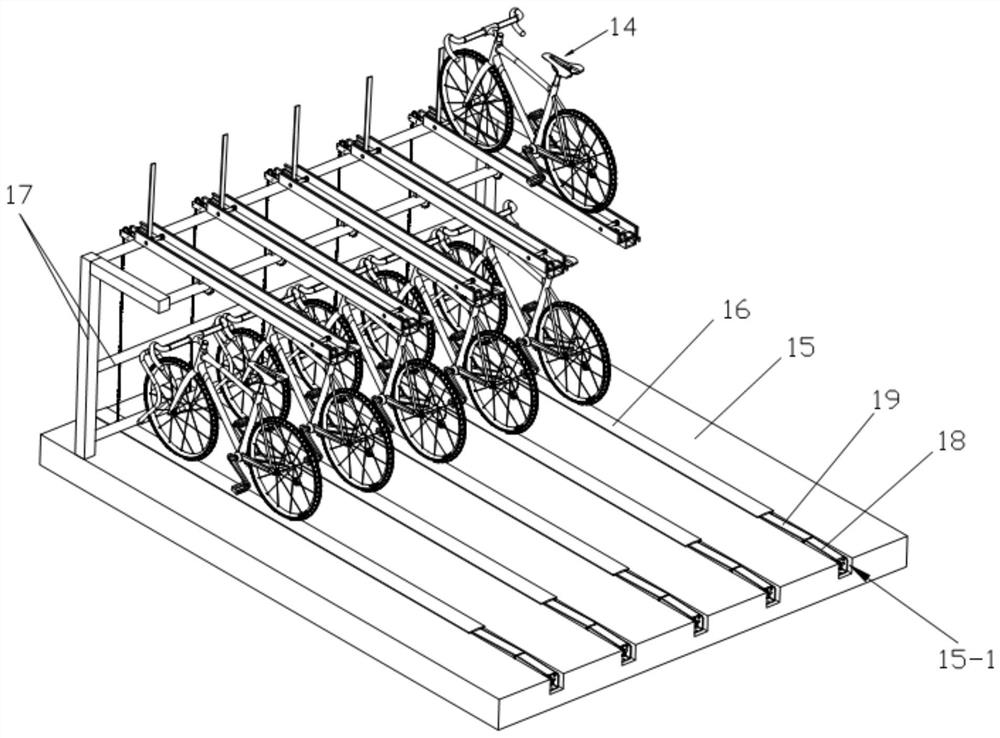

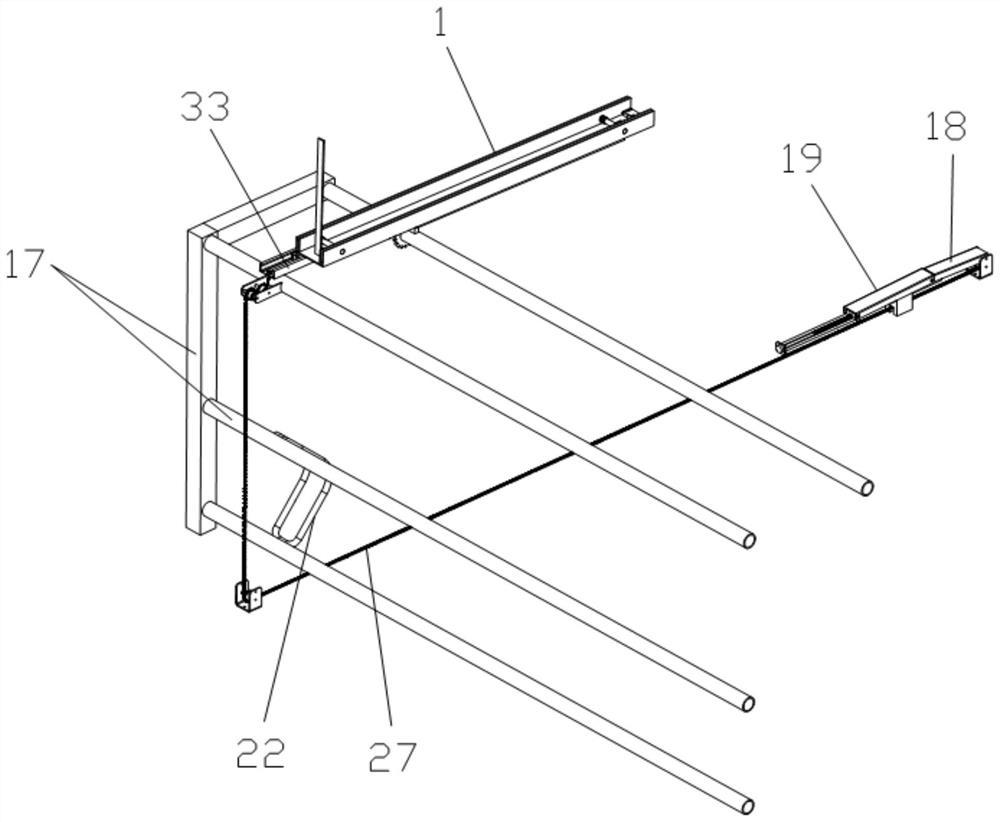

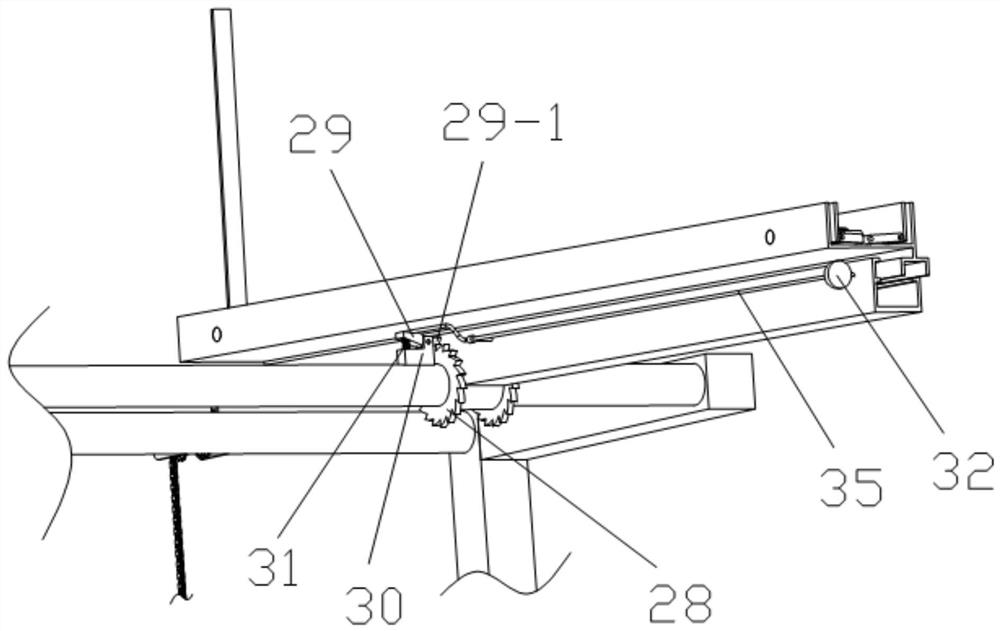

A three-dimensional parking device for bicycles

ActiveCN107119938BSolve the problem of shortage of parking spaceMake full use of the three-dimensional spaceCycle standsElectric vehicle charging technologySprocketControl theory

The invention discloses a bicycle three-dimensional parking device, which comprises a frame, a lower parking device and an upper parking device, the upper parking device includes a bicycle fixing mechanism and a bicycle lifting mechanism; the bicycle fixing mechanism includes a base and a clamping mechanism; The bicycle lifting mechanism includes a lifting seat that is rotatably connected to the frame, a lifting control mechanism that controls the lifting seat to move up and down around the center of rotation, and a control mechanism; the base is arranged on the lifting seat through a linear sliding structure. The sliding direction is parallel to the length direction of the lifting seat and the base; the lifting control mechanism includes a chain and a buffer mechanism, wherein the buffer mechanism is arranged on the ground, one end of the chain is connected with the lifting seat, and the other end bypasses several The sprocket is connected with the buffer mechanism behind. The three-dimensional parking device for bicycles of the present invention can realize parking and picking up the bicycle by manual operation without power supply, and the operation is simple and fast.

Owner:GUANGZHOU HEINER ELECTRIC MFR

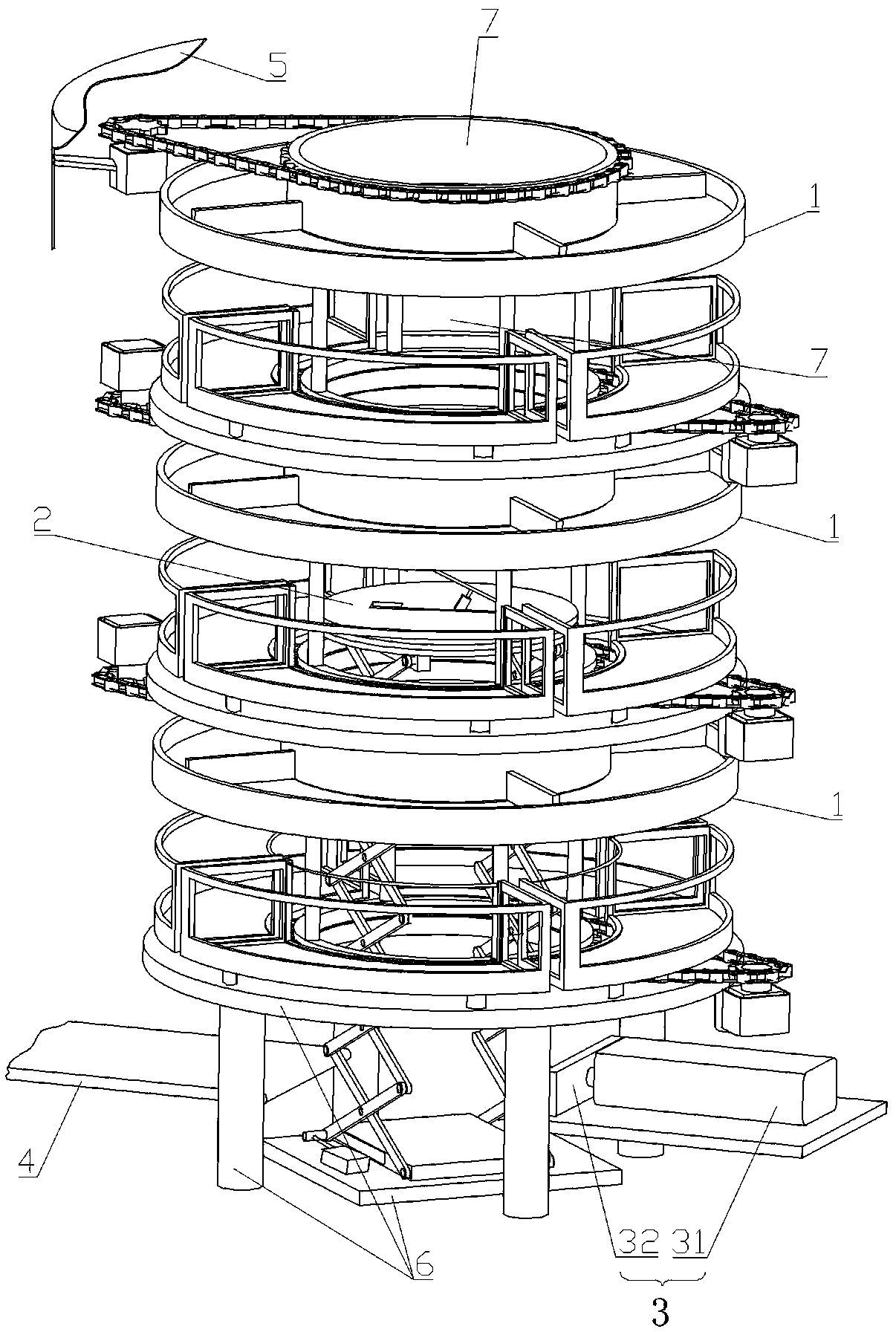

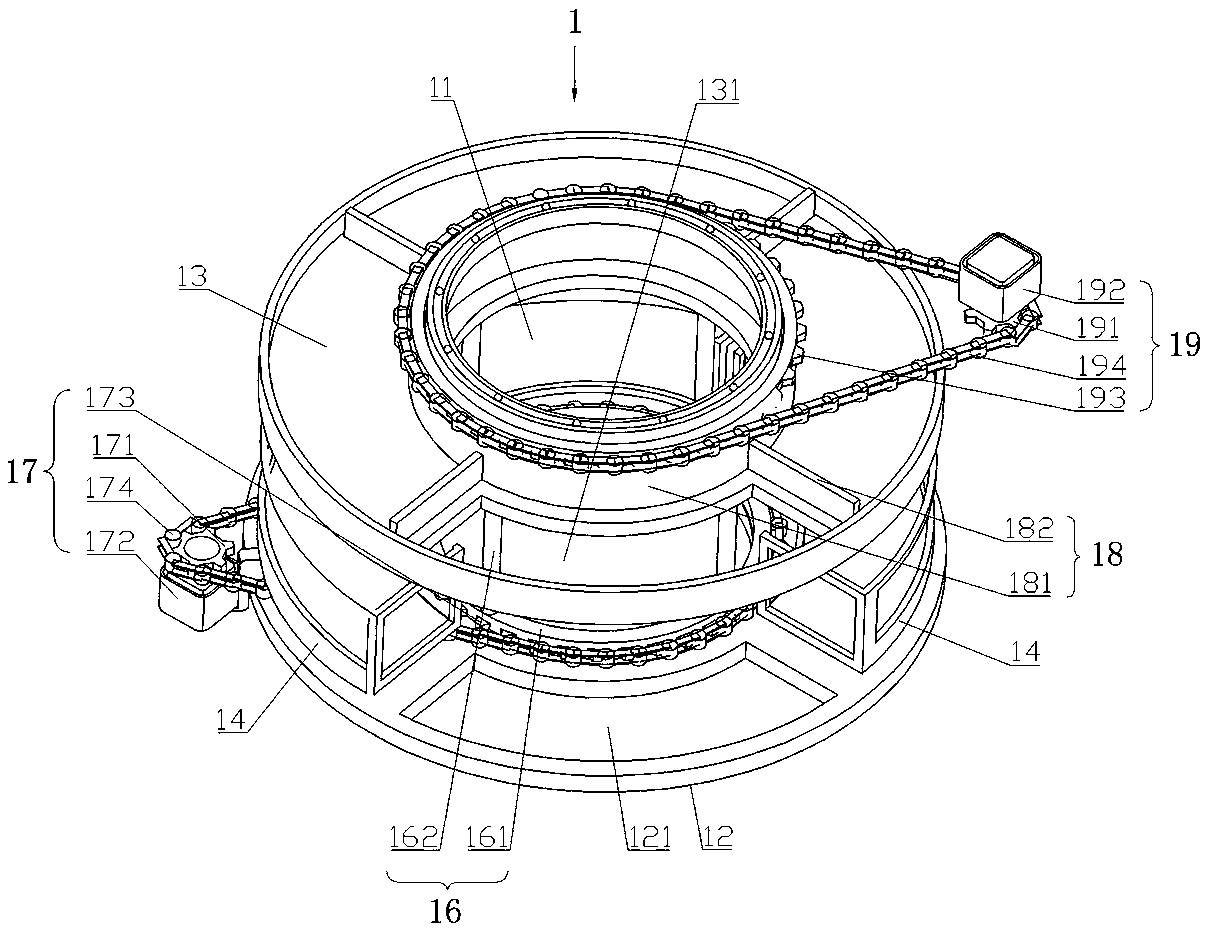

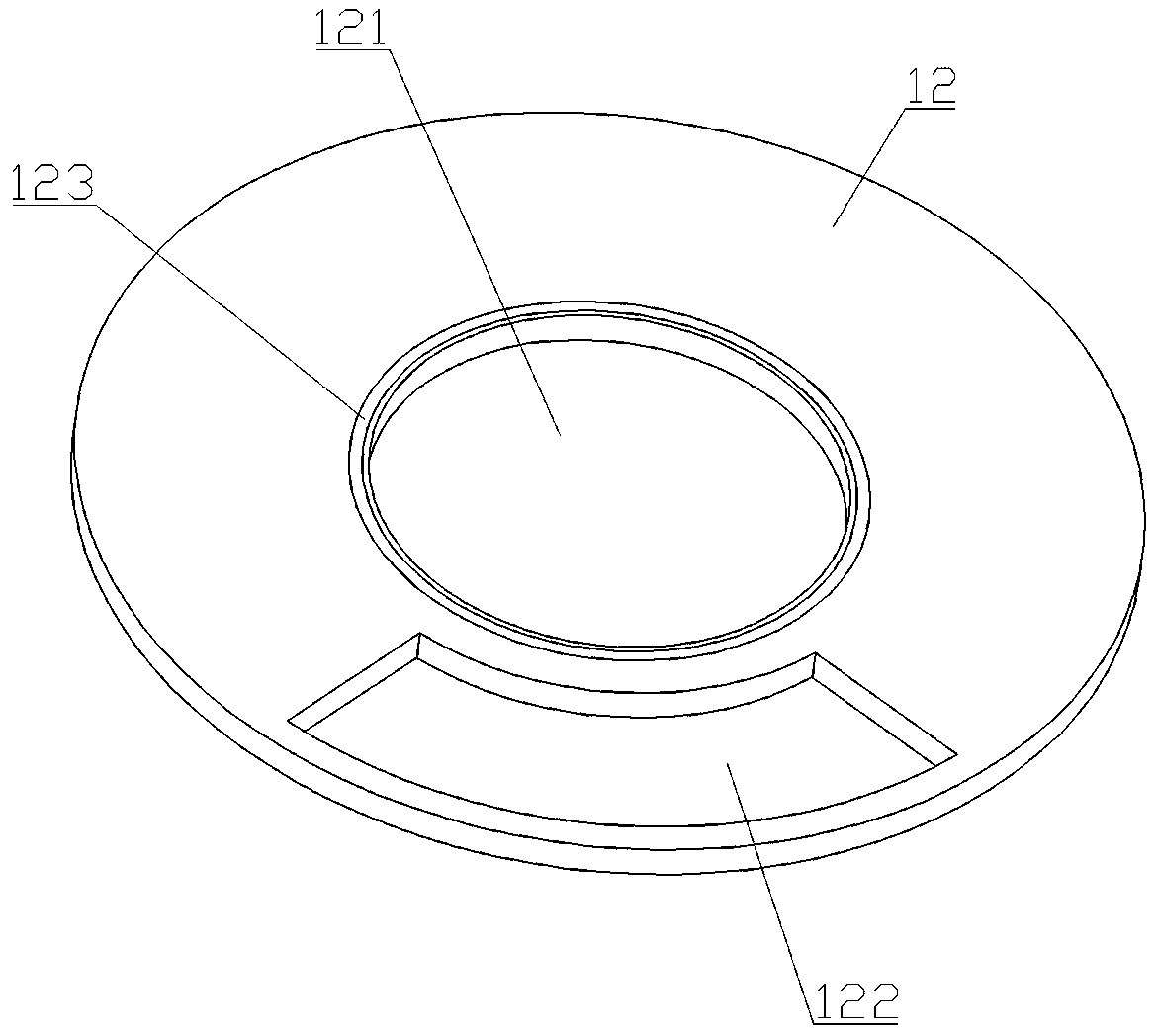

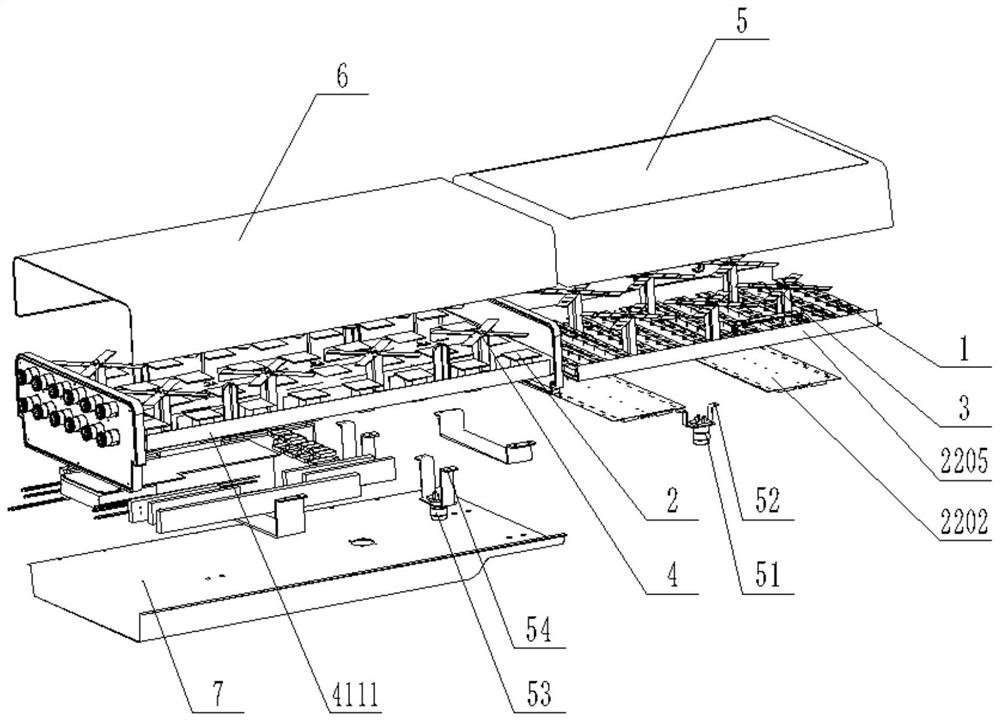

Multi-level stacking combined package sorting-packing-conveying device

ActiveCN108502246BIncrease or decrease the number of stacked layersSmall footprintPackaging automatic controlEngineeringSmall footprint

The invention provides a multi-level stacking combination type parcel sorting, packaging and conveying device which comprises sorting devices, a parcel taking device, a parcel output mechanism and a base. The multiple sorting devices are stacked in the vertical direction. A cylindrical center passage is arranged on the center area of each sorting device. The center passages of all the sorting devices communicate sequentially to form a vertical coherent parcel conveying passage. All the sorting devices are fixedly installed on the base directly or indirectly. The parcel taking device is arranged in the parcel conveying passage and comprises a lifting driver, an object carrying table and a goods taking mechanical hand. The parcel output mechanism comprises a pushing device and a conveying belt. The multi-level stacking combination type parcel sorting, packaging and conveying device is used for sorting, packaging and conveying parcels, the device is formed by stacking the multiple sortingdevices in the vertical direction, the occupied area is small, the number of stacking layers of the sorting devices can be increased or decreased according to the actual use, the sorting device on each layer is provided with a collecting box used for containing the parcels, the three-dimensional space is utilized fully, and the device can contain a large number of parcels.

Owner:NANHUA UNIV

Automatic drawer cabinet

PendingCN109698474AMake full use of the three-dimensional spaceSwitchgear detailsThree-dimensional spaceEngineering

Owner:扬中凯悦铜材有限公司

Fusion antenna

PendingCN113708087AConducive to integrated miniaturization designMake full use of the three-dimensional spaceParticular array feeding systemsRadiating elements structural formsSoftware engineeringThird generation

The invention provides a fusion antenna which comprises a first PCB, a first metal reflecting plate and a second metal reflecting plate. The first PCB is arranged on the first metal reflecting plate, and the first metal reflecting plate and the second metal reflecting plate are sequentially arranged in the length direction; the third antenna array comprises a first branch and a second branch, the first PCB is provided with a first antenna array and a first branch, and the second metal reflecting plate is provided with a second antenna array and a second branch; the first branch is embedded into the first antenna array, the second branch is embedded into the second antenna array, feeding of the first branch is achieved through the first cluster connector and the second cluster connector, the first antenna array works in a 5G network system, and the second antenna array and the third antenna array respectively work in one of a 2G network system, a 3G network system and a 4G network system. The integrated miniaturized design of the fusion antenna is facilitated, and wide-area coverage of 5G signals can be realized.

Owner:WUHAN HONGXIN TELECOMM TECH CO LTD

Method and apparatus for quickly changing road traffic situation by employing module design

ActiveCN100491635CPassage does not affectTraffic will not affectSingle unit pavingsRoad surfaceEngineering

Owner:钟宝驹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com