Micro-nano porous bismuth electrode and preparation method thereof

An electrode, micro-nano technology, applied in the field of bismuth electrodes, can solve the problems that the preparation method needs to be improved and innovated, it is difficult to adapt to large-scale production, and there are many influencing factors, so as to achieve strong microstructure tunability, low market price, and simple process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

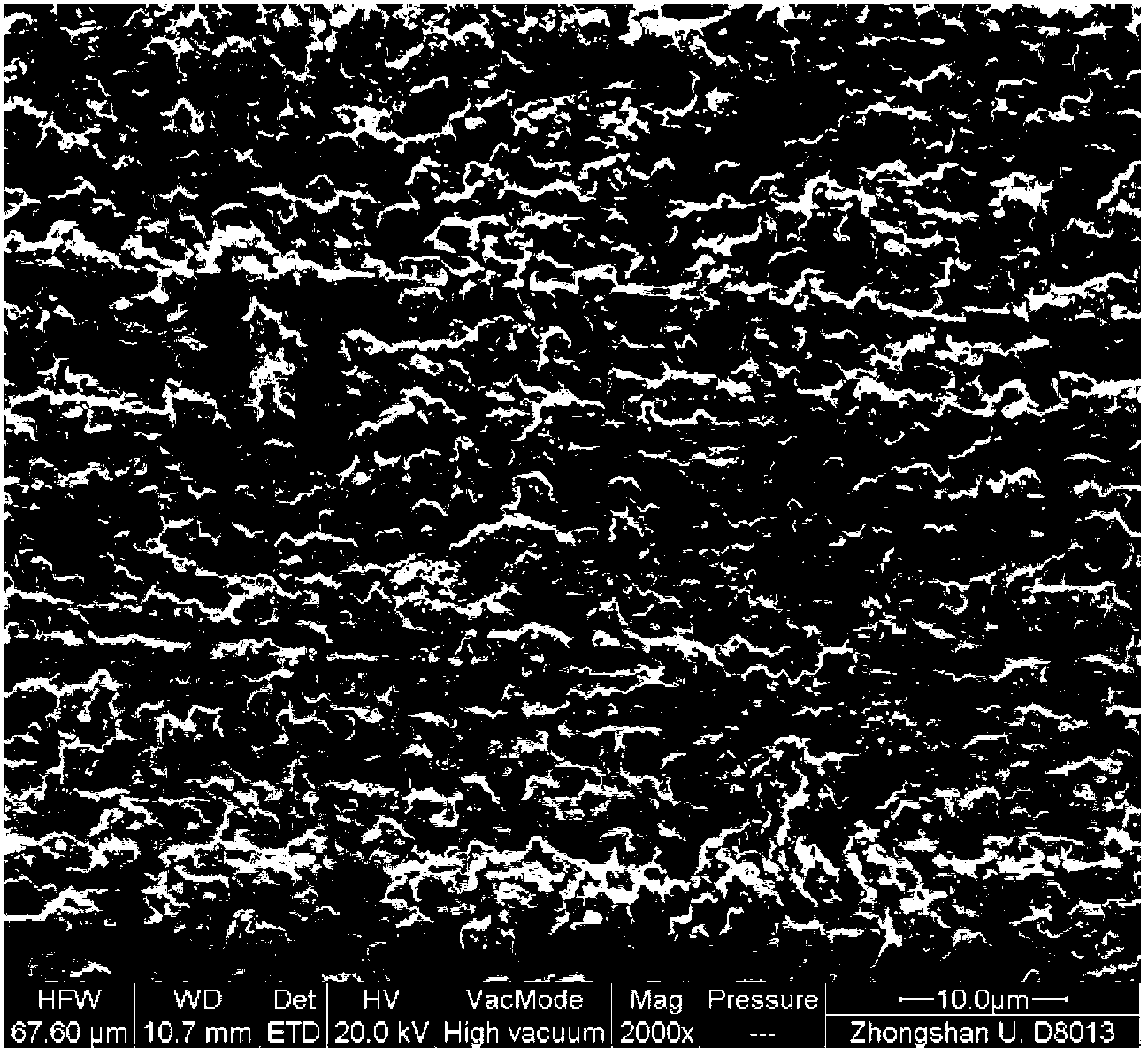

[0052] A micro-nanoporous bismuth electrode is prepared by the following steps:

[0053] (1) Preparation of tin-bismuth alloy electrodes: Weigh 2.657g of metal bismuth (purity: 99.5%) and 0.646g of tin (purity: 99.5%), put them into a quartz glass tube, move them to a resistance furnace and heat for 30 minutes. The internal temperature is 450°C. During the heating process, the quartz glass tube is constantly shaken to fully mix the metal bismuth and tin melts. Finally, the melts are cooled and solidified to form an alloy. Cut the alloy with a saw blade and use 4 in sequence # and 6 # Grinding with metallographic sandpaper to make it flake in shape, the specific size is 0.50cm×0.50cm×0.112mm. Put the alloy into acetone, absolute alcohol, and deionized water for 15 minutes for ultrasonic cleaning, and dry it with nitrogen to obtain a tin-bismuth alloy electrode.

[0054] (2) Tin dissolving treatment: AUTOLAB electrochemical workstation is used to carry out constant potential ...

Embodiment 2

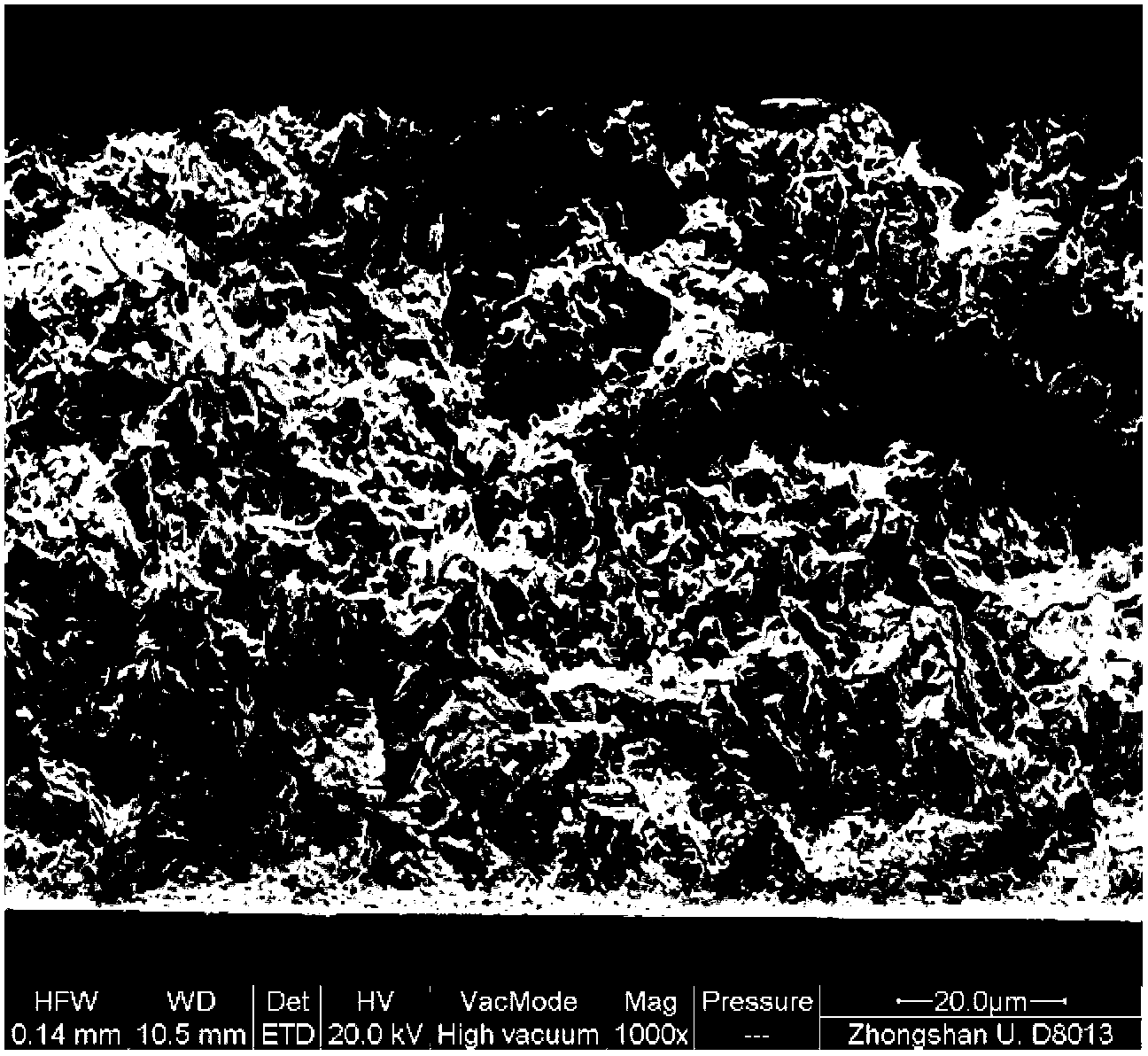

[0057] A micro-nanoporous bismuth electrode is prepared by the following steps:

[0058] (1) Preparation of tin-bismuth alloy electrode: Weigh 1.380g of metal bismuth (purity 99.5%) and tin (purity 99.5%) 1.827g, put them into a quartz glass tube, move to a resistance furnace and heat for 30 minutes, the furnace The internal temperature is 450°C. During the heating process, the quartz glass tube is constantly shaken to fully mix the metal bismuth and tin melts. Finally, the melts are cooled and solidified to form an alloy. Cut the alloy with a saw blade and use 4 in sequence # and 6 # Grinding with metallographic sandpaper to make it flake in shape, the specific size is 0.50cm×0.50cm×0.112mm. Put the alloy into acetone, absolute alcohol, and deionized water for 15 minutes for ultrasonic cleaning, and dry it with nitrogen to obtain a tin-bismuth alloy electrode.

[0059] (2) Tin dissolving treatment: AUTOLAB electrochemical workstation is used to carry out constant potential...

Embodiment 3

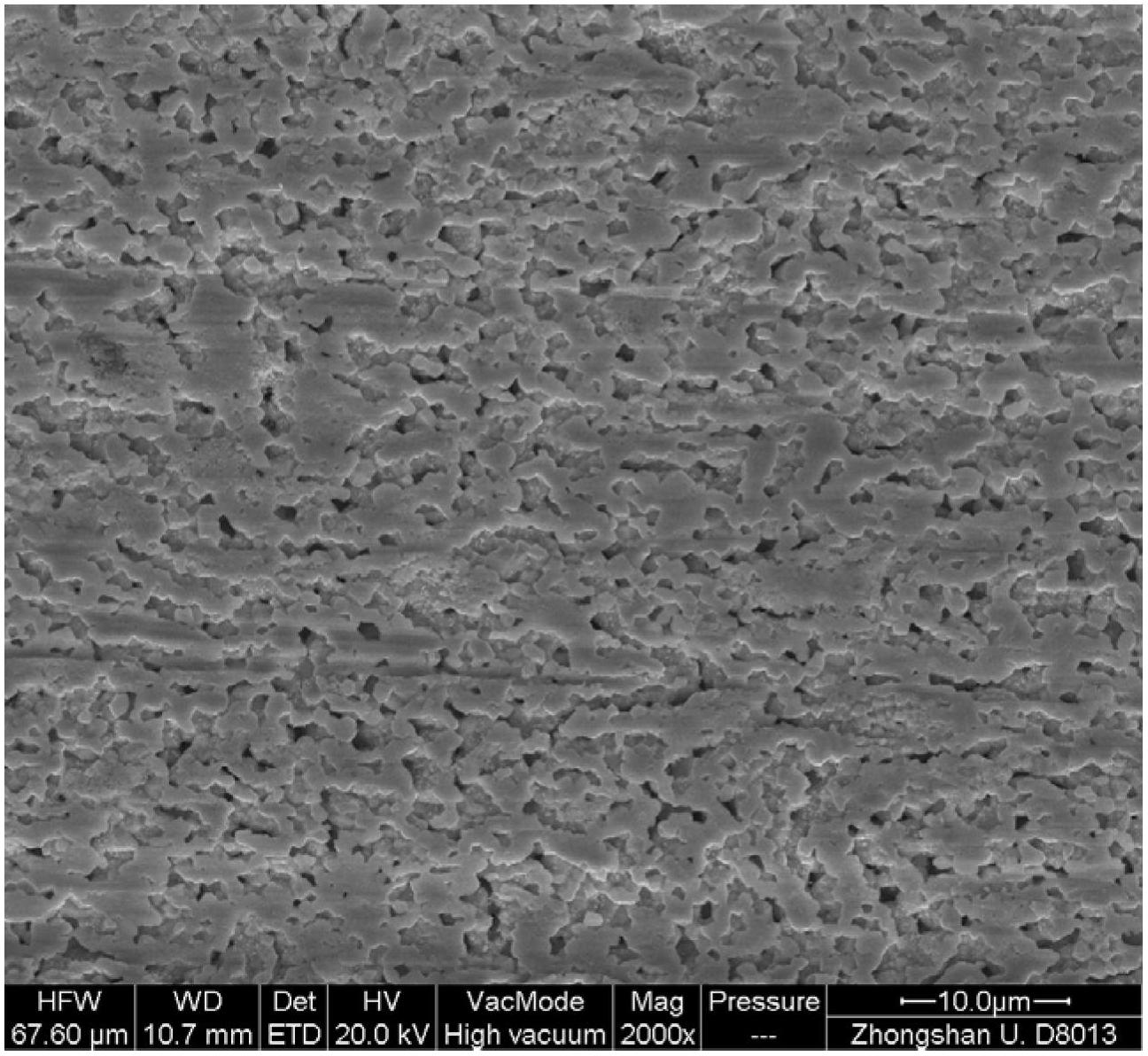

[0062] A micro-nanoporous bismuth electrode is prepared by the following steps:

[0063] (1) Preparation of tin-bismuth alloy electrodes: Weigh 2.657g of metal bismuth (purity: 99.5%) and 0.646g of tin (purity: 99.5%), put them into a quartz glass tube, move them to a resistance furnace and heat for 30 minutes. The internal temperature is 450°C. During the heating process, the quartz glass tube is constantly shaken to fully mix the metal bismuth and tin melts. Finally, the melts are cooled and solidified to form an alloy. Cut the alloy with a saw blade and use 4 in sequence # and 6 # Grind with metallographic sandpaper to make it strip-shaped, with a specific size of 0.10cm×0.10cm×1.00cm. Put the alloy into acetone, absolute alcohol, and deionized water for 15 minutes for ultrasonic cleaning, and dry it with nitrogen to obtain a tin-bismuth alloy electrode.

[0064] (2) Tin dissolving treatment: AUTOLAB electrochemical workstation is used to carry out constant potential tin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Hole wall thickness | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com