A filling food forming machine

A forming machine and food technology, which is applied in dough forming and cutting combination, food science, dough processing, etc. It can solve the problems of insufficient space utilization and large equipment occupation area, so as to save floor space and work stations The effect of occupying space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

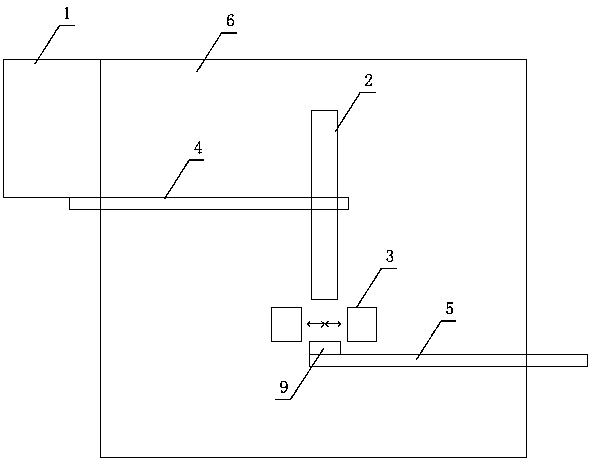

[0035] A filling food forming machine comprises a dough input device 1, a filling device 2, a molding device 3 and a conveyor belt, the conveyor belt includes a dough conveyor belt 4 and a finished product conveyor belt 5, and the dough conveyor belt 4 and a finished product conveyor belt 5 are all installed on the bracket 6, and there is a height difference between the dough conveyor belt 4 and the finished product conveyor belt 5, the filling device 2 and the Forming device 3, described filling device 2, forming device 3 are arranged on the same vertical plane, described filling device 2 is filling station 7, described forming device 3 is forming station 8, described The horizontal projections of filling station 7 and forming station 8 overlap each other.

[0036] After the dough is processed by the dough input device 1, as the dough conveyor belt 4 is conveyed to the bottom of the filling device 2, the filling device 2 moves downwards to convey the fillings down to the doug...

Embodiment 2

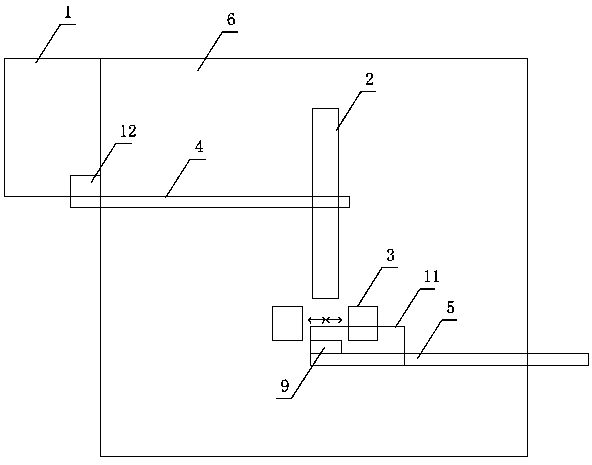

[0039] A filling food forming machine comprises a dough input device 1, a filling device 2, a molding device 3 and a conveyor belt, the conveyor belt includes a dough conveyor belt 4 and a finished product conveyor belt 5, and the dough conveyor belt 4 and a finished product conveyor belt 5 are all installed on the bracket 6, and there is a height difference between the dough conveyor belt 4 and the finished product conveyor belt 5, the filling device 2 and the Forming device 3, described filling device 2, forming device 3 are arranged on the same vertical plane, described filling device 2 is filling station 7, described forming device 3 is forming station 8, described The horizontal projections of filling station 7 and forming station 8 overlap each other.

[0040] At least one molding die 9 is arranged on the finished product conveyor belt 5 . The forming device 3 is located above the forming mold 9 . The finished product conveyor belt 5 located below the forming device 3 ...

Embodiment 3

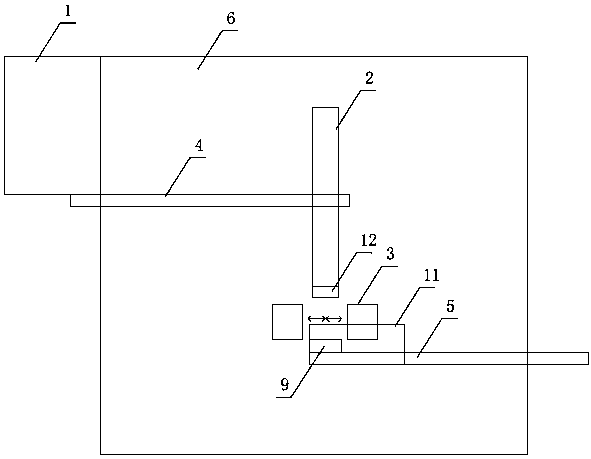

[0046] A filling food forming machine comprises a dough input device 1, a filling device 2, a molding device 3 and a conveyor belt, the conveyor belt includes a dough conveyor belt 4 and a finished product conveyor belt 5, and the dough conveyor belt 4 and a finished product conveyor belt 5 are all installed on the bracket 6, and there is a height difference between the dough conveyor belt 4 and the finished product conveyor belt 5, the filling device 2 and the Forming device 3, described filling device 2, forming device 3 are arranged on the same vertical plane, described filling device 2 is filling station 7, described forming device 3 is forming station 8, described The horizontal projections of filling station 7 and forming station 8 overlap each other.

[0047] At least one molding die 9 is arranged on the finished product conveyor belt 5 . The forming device 3 is located above the forming mold 9 . The finished product conveyor belt 5 located below the forming device 3 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com